Petroleum steel tube capable of anti hydrogen sulfide stress corrosion and its manufacturing method

A technology for stress corrosion and petroleum steel pipes, applied in the manufacture of tools, drill pipes, casings, etc., can solve the problems of low threshold value of resistance to hydrogen sulfide stress corrosion, quenching and bending deformation of long steel pipes, and unfavorable resistance to hydrogen sulfide stress corrosion, etc. The effect of good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

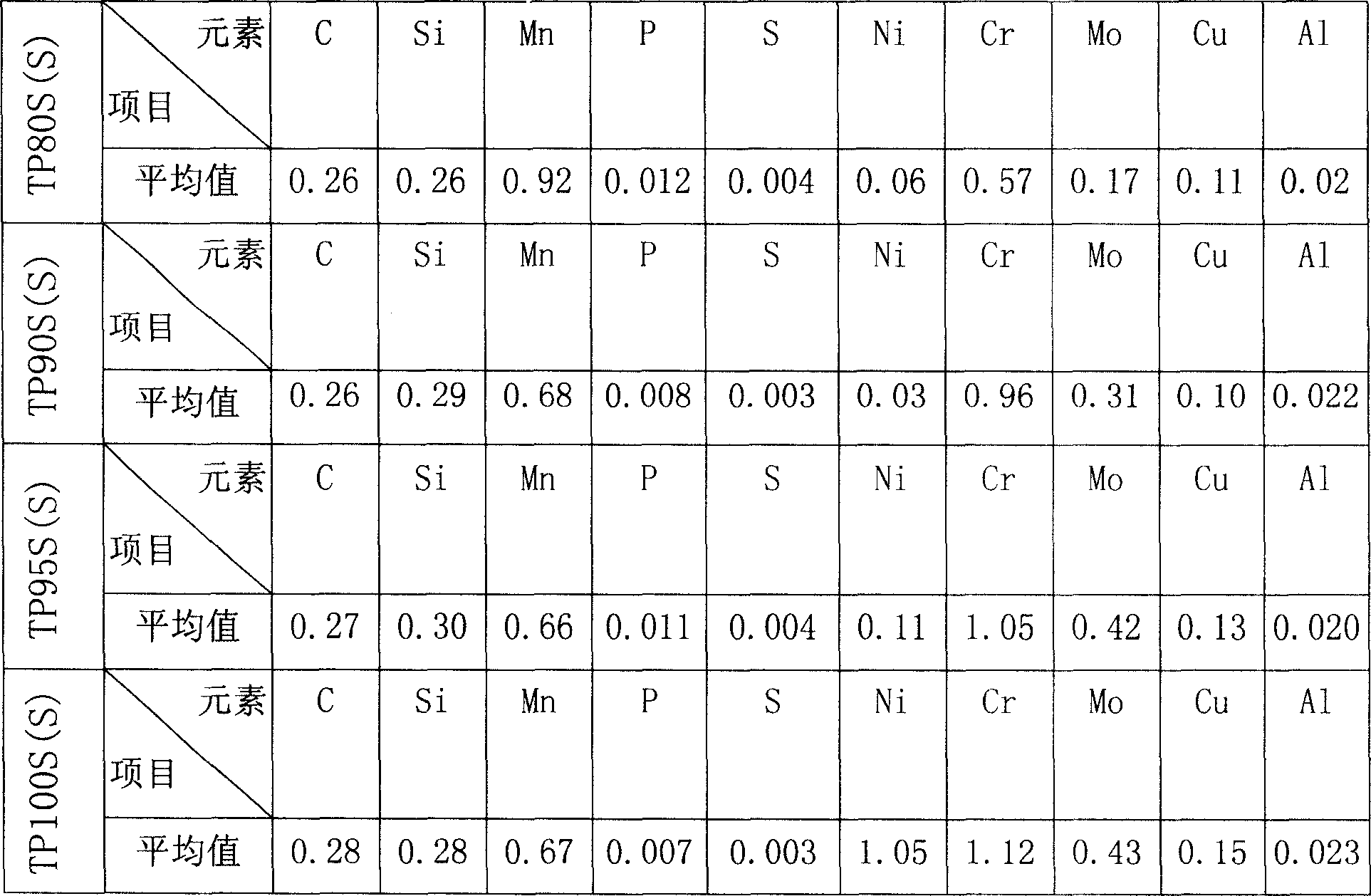

[0018] The present invention is based on the following technical ideas: To solve the technical problem of low threshold value of hydrogen sulfide stress corrosion resistance of high-strength hydrogen sulfide-resistant steel pipes in hydrogen sulfide stress corrosion sensitive areas, harmful elements such as P and S and strip-shaped MnS It has an extremely adverse effect on the steel pipe's resistance to hydrogen sulfide stress corrosion, and at the same time solves the quality problems of quenching, bending deformation and cracks in long steel pipes. According to experimental analysis, sulfide stress corrosion cracking is more likely to occur at normal temperature than at higher or lower than normal temperature. Most researchers believe that the cracking sensitivity is the highest at 24±3°C, and when the temperature is at or above 80°C , Generally, sulfide stress corrosion cracking does not occur. Contains H 2 The solution of S is slightly acidic, and the cracking sensitivity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com