Plasma treatment device

A plasma and processing device technology, which is applied in the field of substrate devices, can solve problems such as processing chamber pollution, and achieve the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

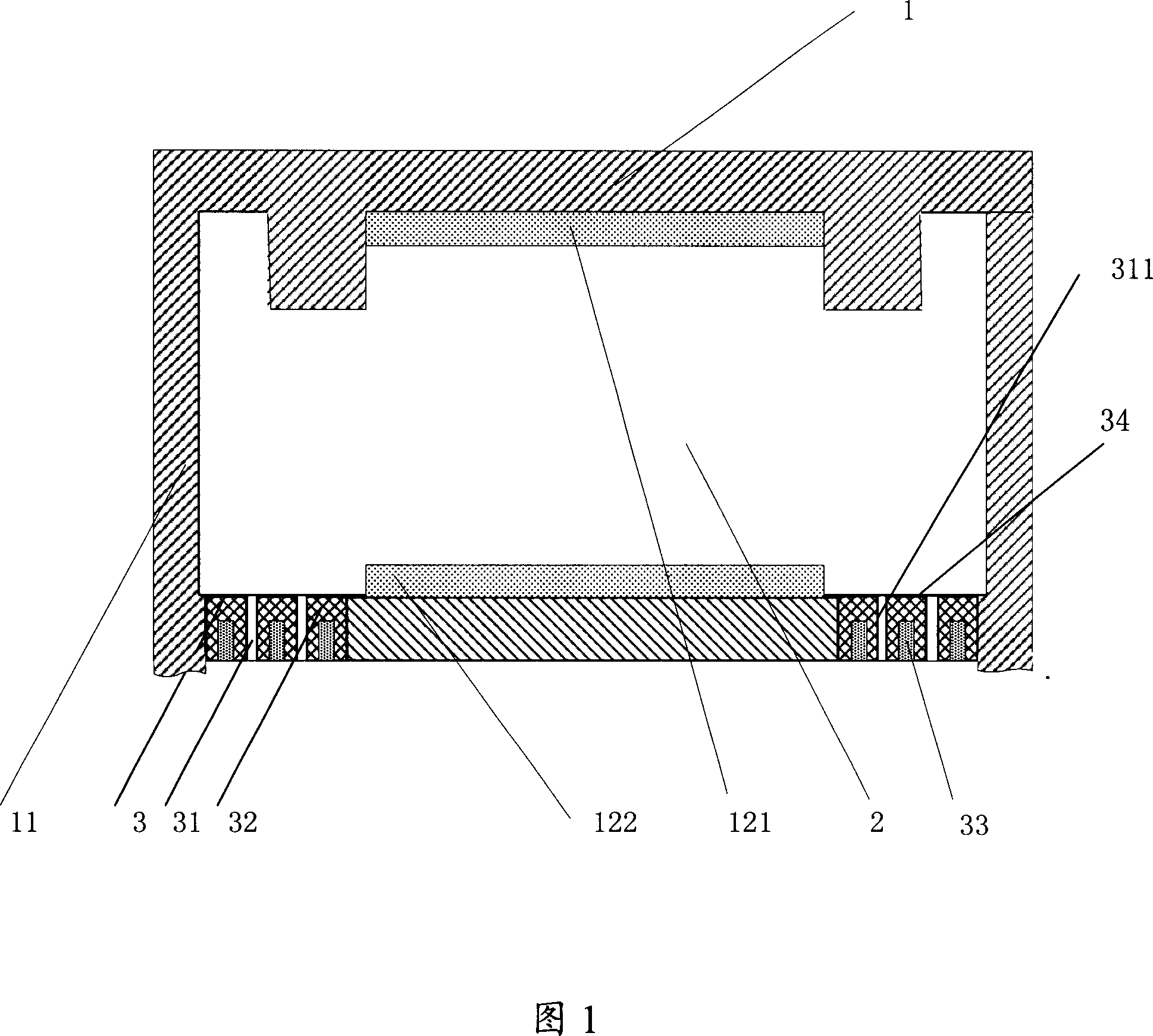

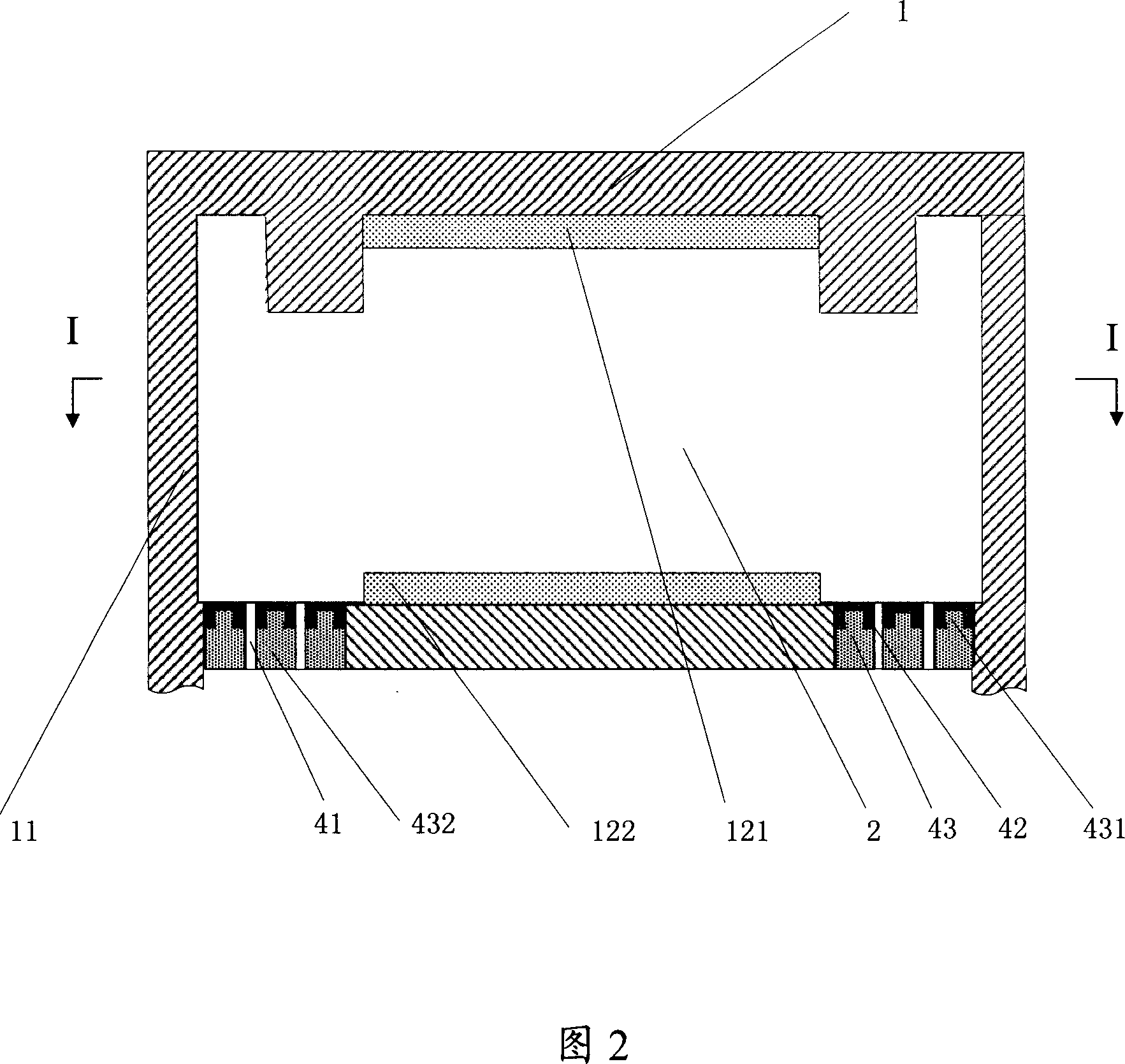

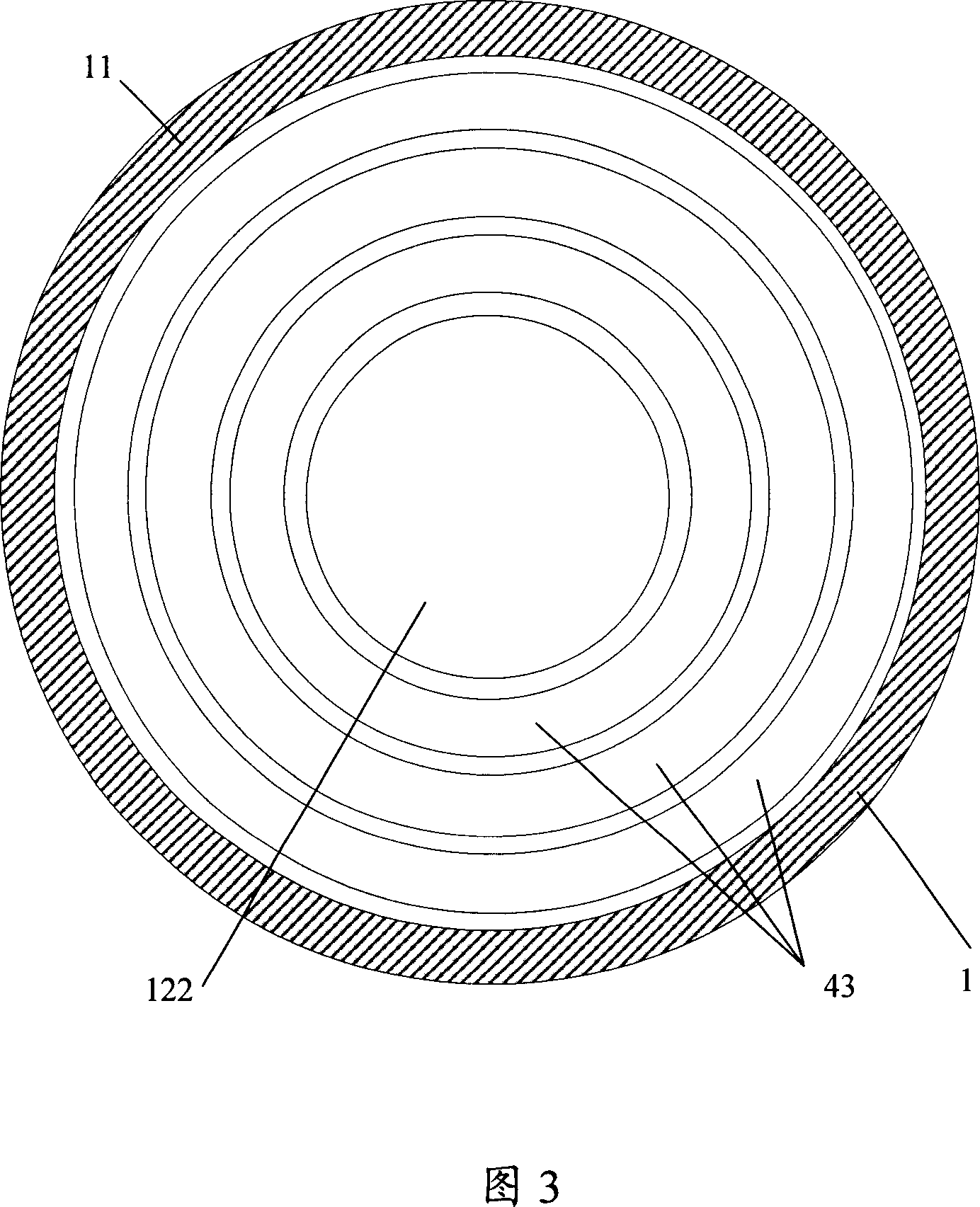

[0050] Please refer to FIG. 1 . FIG. 1 is a schematic structural diagram of an embodiment of the plasma processing apparatus of the present invention. In this embodiment, the plasma processing apparatus 1 has a processing chamber 11, the processing chamber 11 is substantially cylindrical, and the side walls of the processing chamber are substantially vertical, and there are upper electrodes arranged parallel to each other in the processing chamber 11. 121 and the lower electrode 122. Generally, the area 2 between the upper electrode 121 and the lower electrode 122 is the processing area, which will generate high frequency energy to ignite and maintain the plasma. A workpiece to be processed is placed above the lower electrode 122, and the workpiece may be a semiconductor substrate to be etched or processed or a glass plate to be processed into a flat panel display. The reaction gas is input into the processing chamber 11 from a gas injection port (not shown), and one or more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com