Well drilling method of multibranch well

A multi-branched and new technology, applied in wellbore/well components, directional drilling, earth-moving drilling, etc., can solve the problems of unreliable positioning, small main wellbore, can not find, etc., to achieve high operational safety and reliability, construction The effect of obvious signal and low operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Method for a new multilateral well.

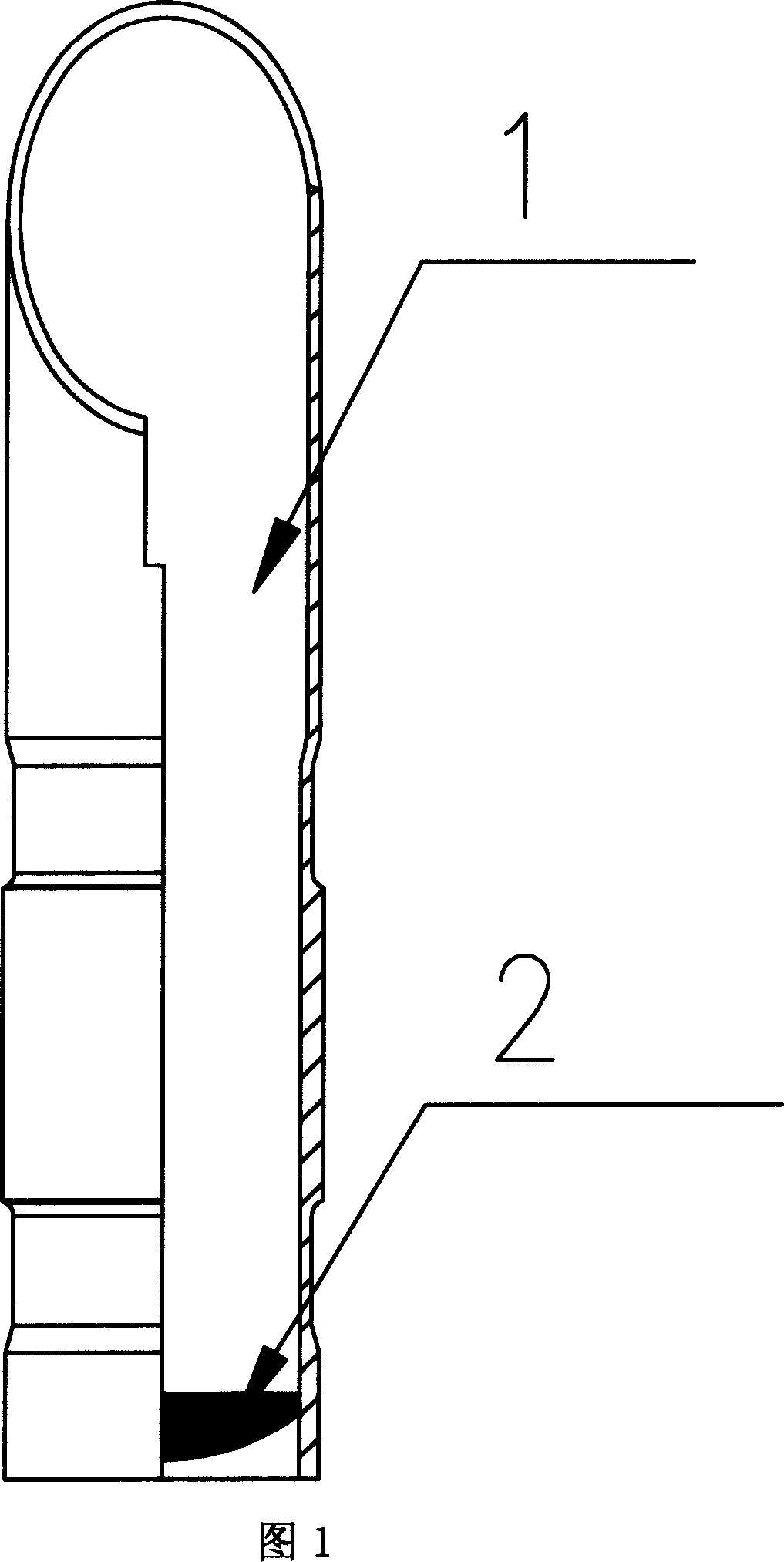

[0039] As shown in Figure 1, it is a positioning device 1 for drilling a multilateral well, which is a permanent positioning device: the positioning device is designed with a sealing part 2 to separate the upper wellbore from the lower wellbore of the main wellbore window; , the diameter of the main wellbore is only reduced by one annular wall thickness of the positioning device 1 .

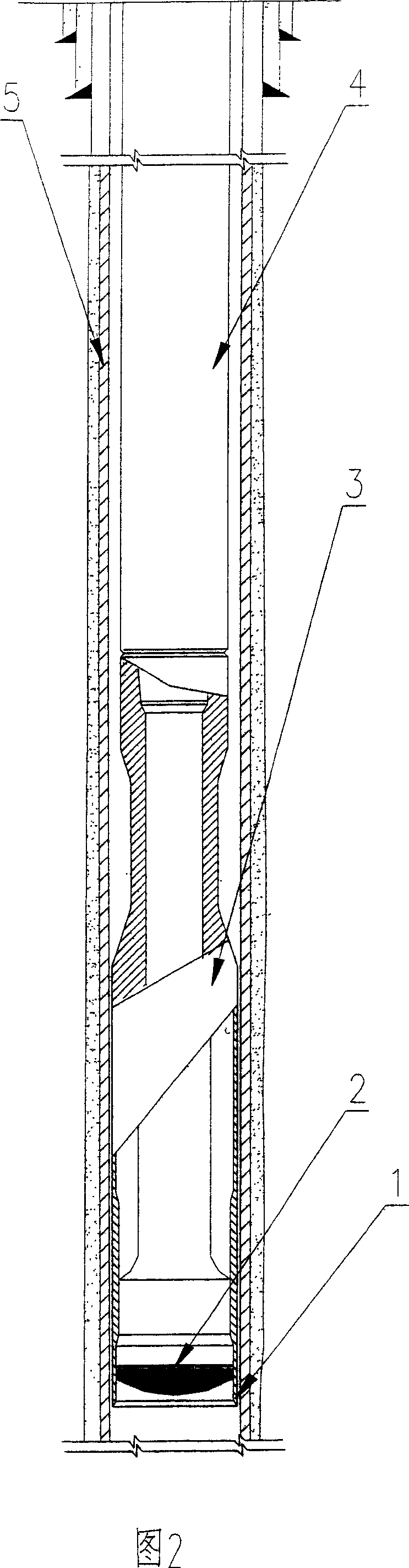

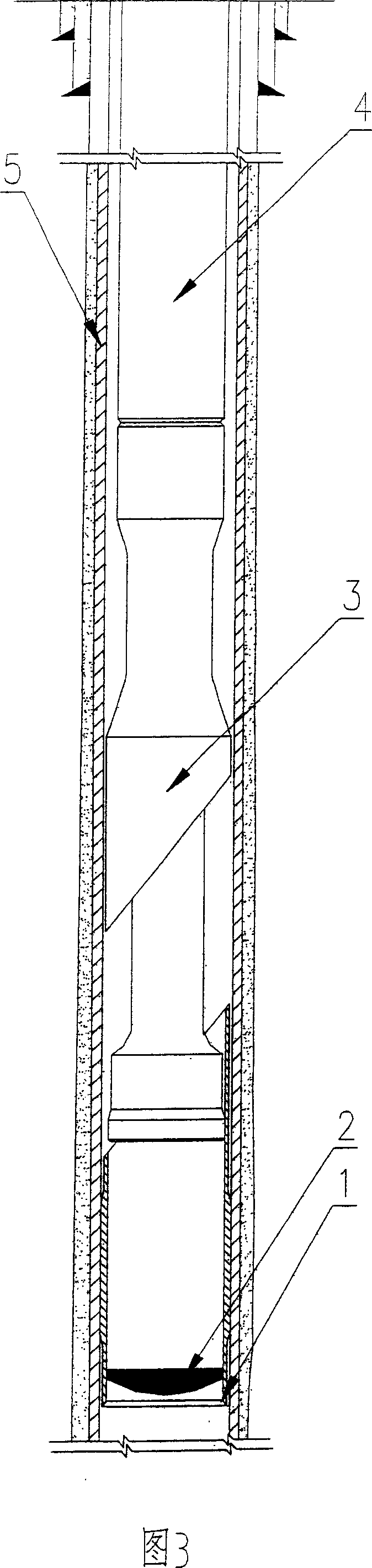

[0040] As shown in Figure 2, it is for going into the permanent positioning device 1 operation. Run and seal a permanent positioning device 1 at the window opening position of the main wellbore, so as to separate the upper part and the lower part of the window opening position of the main wellbore. The positioning device 1 is connected with the downhole pressing tool 3 through the drill pipe 4 and the pressing equipment at the wellhead. After pressing, the positioning device 1 shown in FIG. On the inner wall of the casing 5, the requiremen...

Embodiment 2

[0049] Embodiment 2: Well sidetracking branch well method.

[0050] When the oil (gas) field is in the production process, due to various reasons, it is necessary to drill a new wellbore and complete the well, so that the oil (gas) and water wells can resume production and achieve normal production. It is necessary to seal a permanent positioning device 1 in the depth of the branch well, carry out the operation of positioning device, the operation of the inclined device, the drilling tool for directional window opening, directional drilling, casing cementing and completion Such as conventional construction operations, recovery inclined device operations.

[0051] Since the positioning device 1 is designed with a sealing member 2 separated from the lower part, the upper part and the lower part of the window opening position of the main wellbore are sealed off. Therefore, after the above operations are completed, if it is necessary to seal off the lower wellbore, it is not nece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com