Electrolyte, lithium ion cell containing same and preparing process thereof

A technology of electrolyte and electrolyte, applied in the field of electrolyte, can solve the problems of battery overcharge safety and low-temperature discharge performance at the same time, and achieve the effects of enhancing overcharge safety, reducing production costs, and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

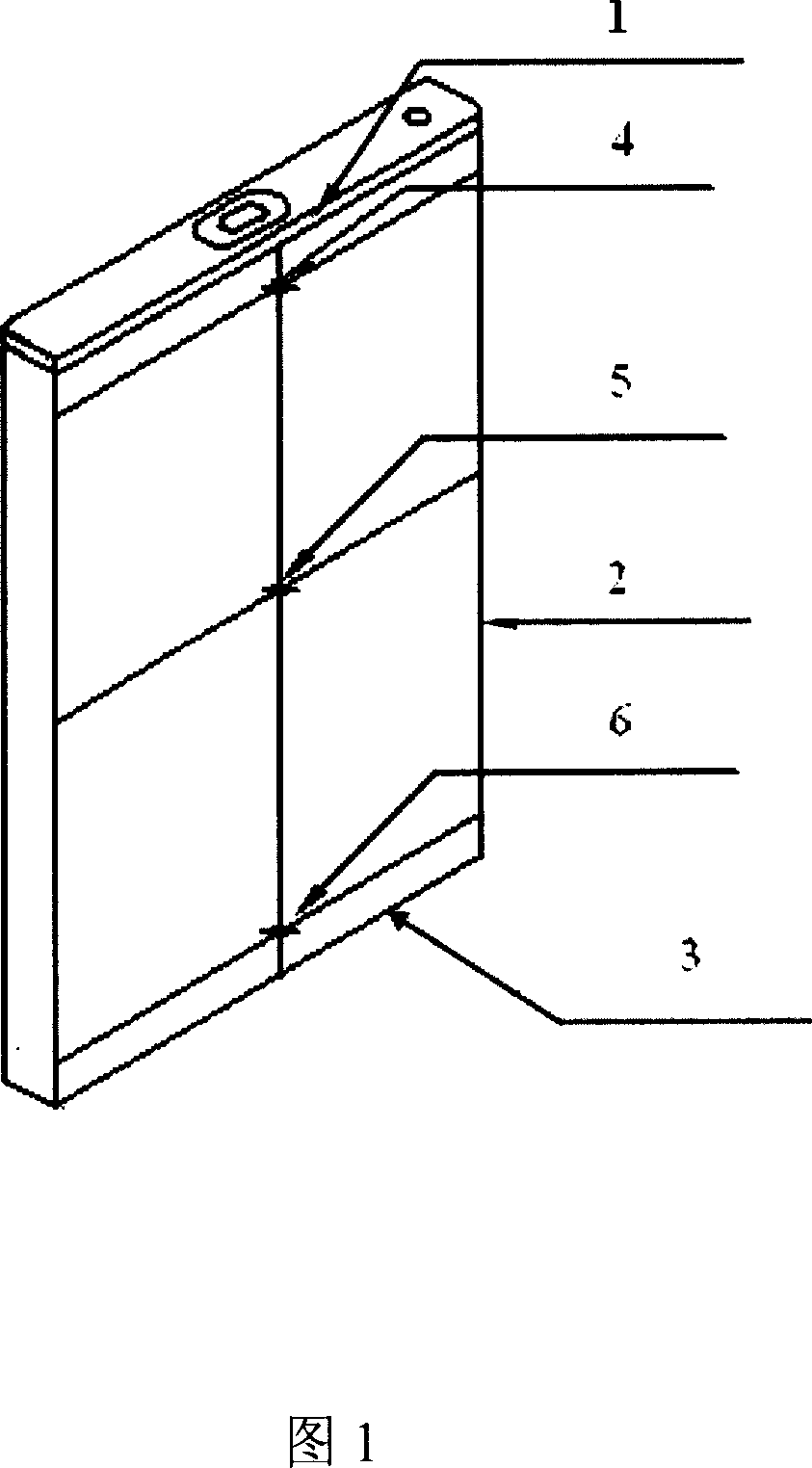

Image

Examples

preparation example Construction

[0025] The preparation method of the electrolytic solution provided by the present invention comprises mixing the lithium salt as the electrolyte, the organic solvent and the additive, wherein the additive is selected from lithium carbonate, lithium sulfate, lithium sulfite, lithium nitric acid One or more of salt, lithium nitrite and lithium aluminate. Based on the total amount of the electrolyte, the additive is added in an amount of 0.1-5.0% by weight, preferably 0.3-2.0% by weight.

[0026] Although the additives with various particle sizes can achieve the purpose of the present invention, preferably, the particle diameter of the inorganic salt used as the additive of the present invention is below 25 microns. Therefore, it is preferable to refine the inorganic salts. The method of the refinement can be various refinement methods. For example, the inorganic salts as additives can be ball milled at 100-250 rpm in a ball mill for 1-8 minutes. Hours, first turn forward for 1...

Embodiment 1

[0038] This example illustrates the electrolyte solution provided by the present invention, batteries containing the electrolyte solution and their preparation methods.

[0039] (1) Preparation of electrolyte

[0040] 50 g Li 2 CO 3 , in a ball mill with a speed of 150 rpm for 4 hours, rotate forward for 10 minutes, then reverse for 10 minutes, repeat this way, and pass through a 200-mesh sieve after ball milling to obtain Li 2 CO 3 powder. The results of particle size analysis of the obtained powder show that the particle diameter is less than 1.562 micron Li 2 CO 3 10% smaller than 3.983 micron Li 2 CO 3 50% Li smaller than 22.24 microns 2 CO 3 95%.

[0041] In 210 ml of ethylene carbonate: ethyl methyl carbonate: diethyl carbonate: dimethyl carbonate = 2: 3: 1: 1 (volume ratio) mixed solvent, add 31.90 grams of LiPF 6 Prepare a solution of 1.0 mol / liter; let it stand for 30 minutes, and wait for the temperature of the solution to cool to ambient temperature, and ...

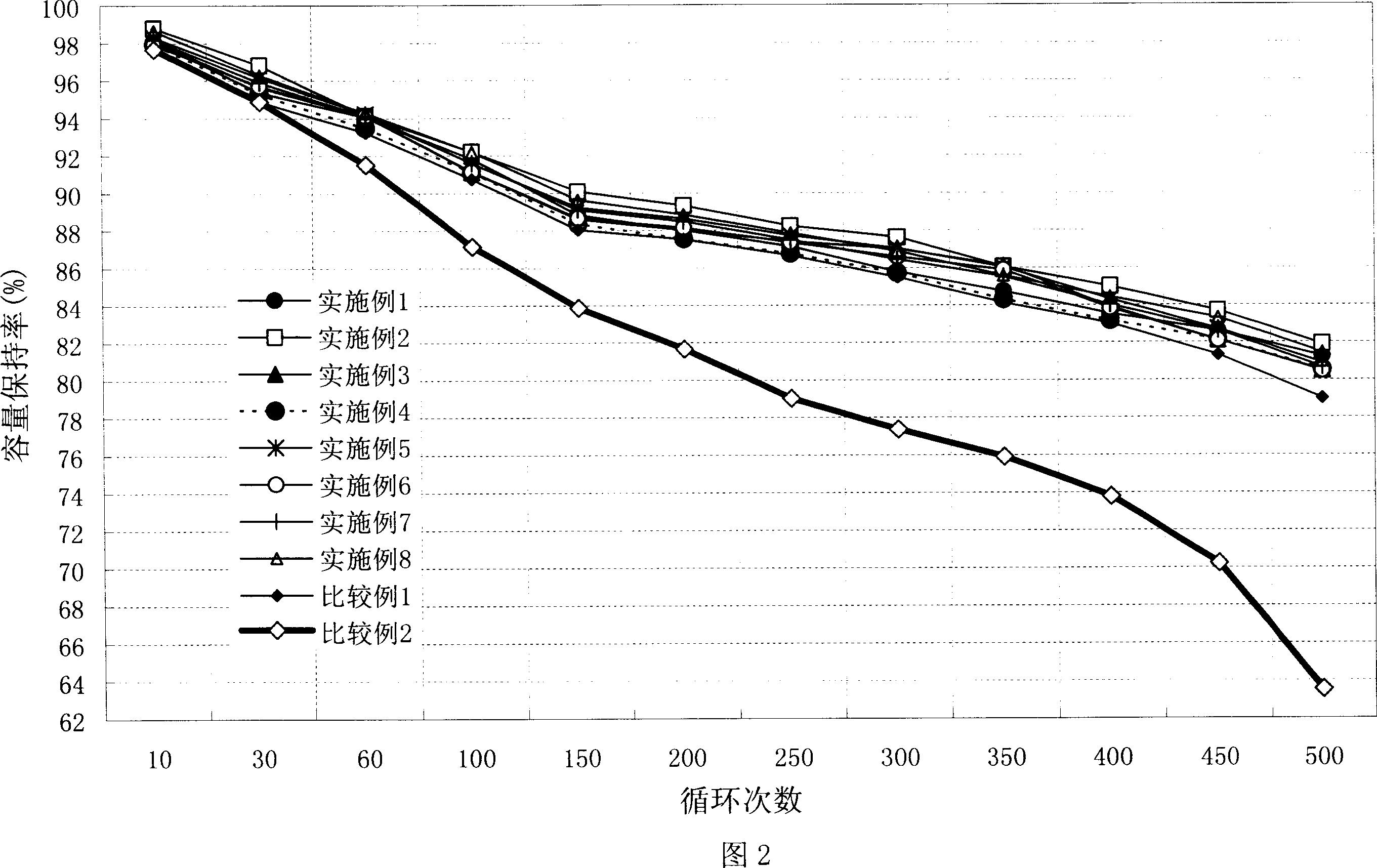

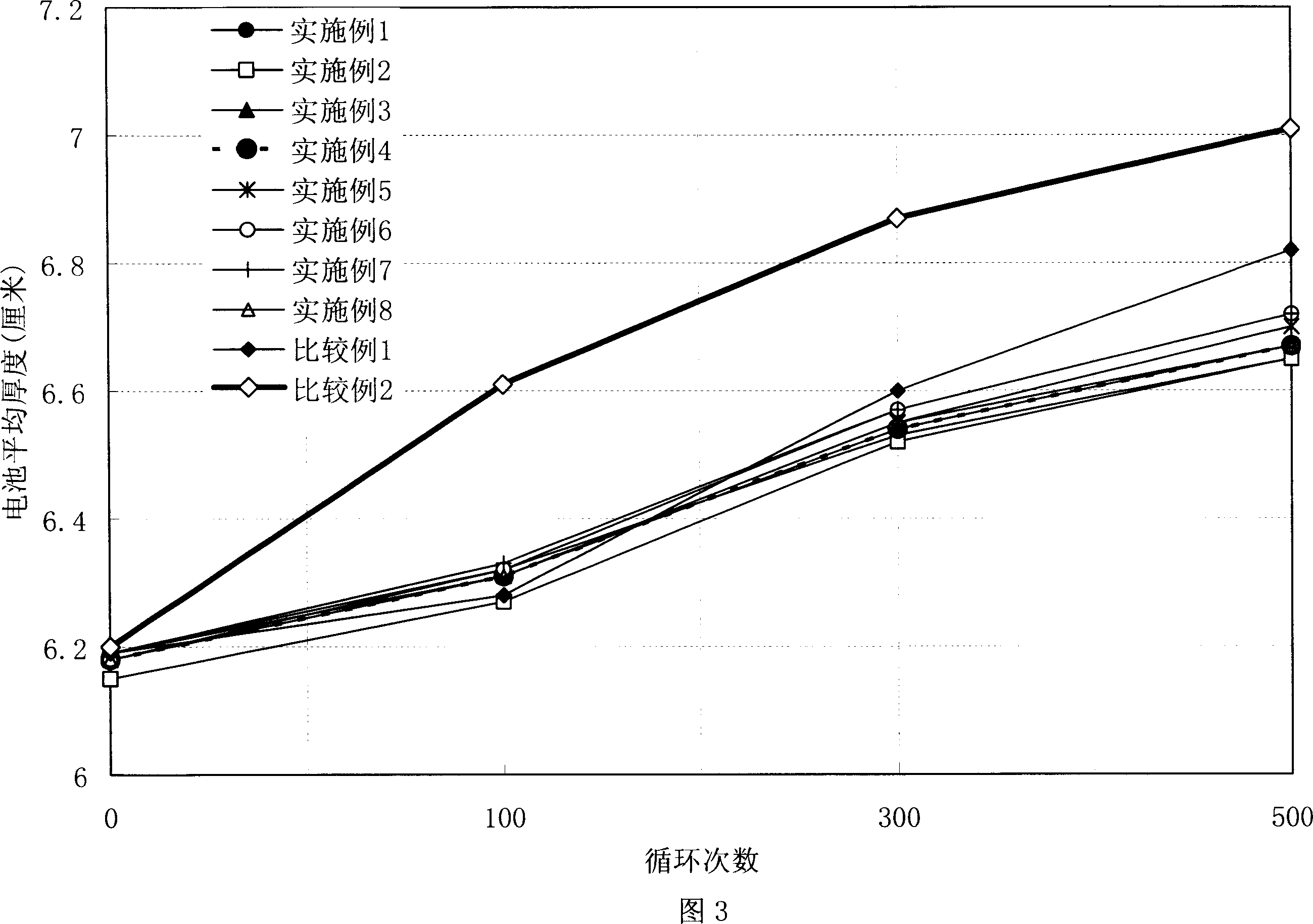

Embodiment 2-8

[0049] Electrolyte and lithium ion battery were prepared according to the method of Example 1, the difference was the type and amount of inorganic additives added and based on the total amount of the electrolyte, the content of additives in the electrolyte was shown in Table 1 below.

[0050] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com