Drying apparatus for heat-sensitive material

A technology for heat-sensitive materials and drying equipment, applied in lighting and heating equipment, heating to dry solid materials, and no heating to dry solid materials, etc. The effect of improving production efficiency, fast drying and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

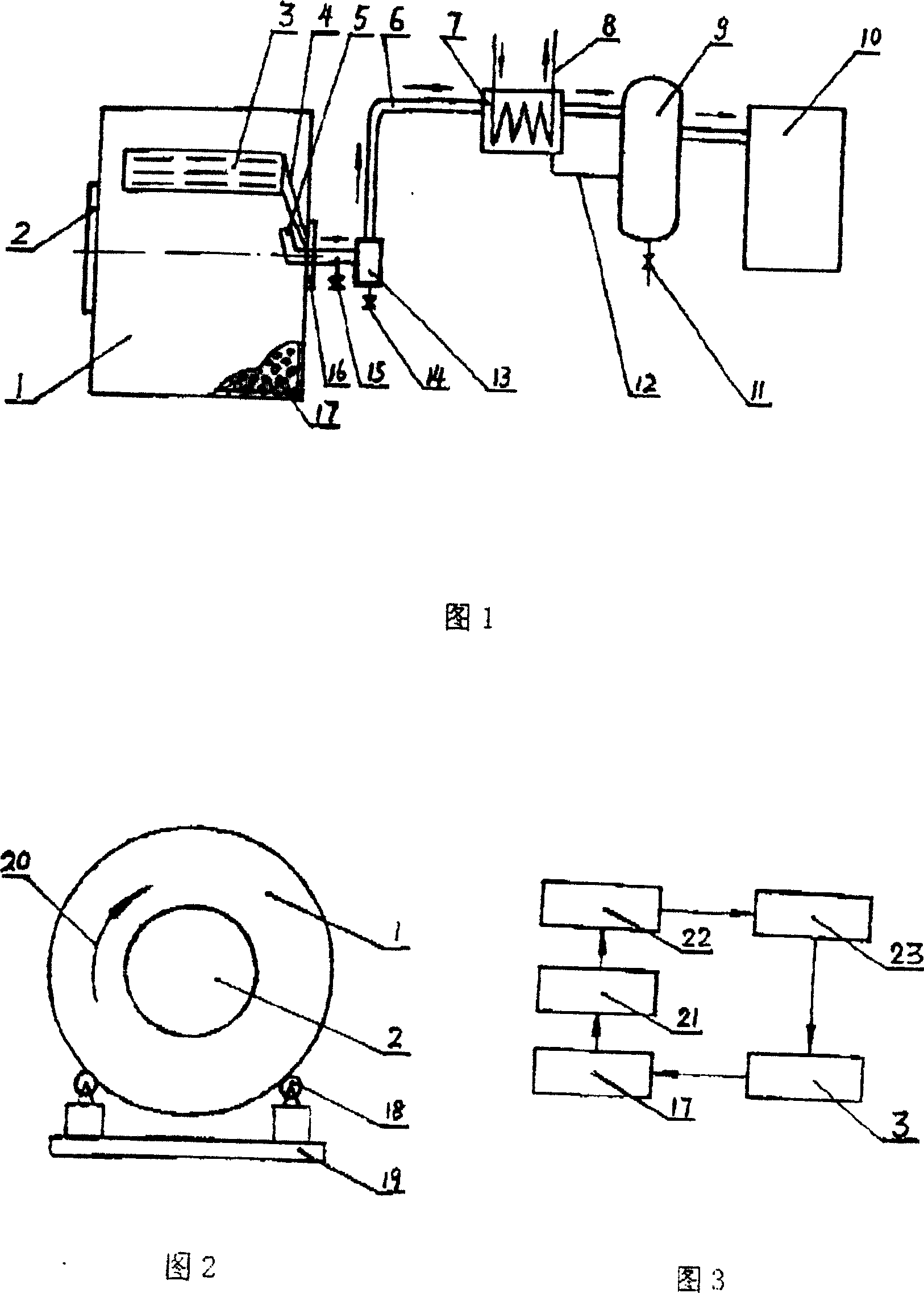

[0009] Further illustrate the specific implementation below in conjunction with the accompanying drawings: rotating cylinder 1, drying chamber door 2, far-infrared radiation heater or microwave generator system 3, heater support 4, vacuum suction port 5, wet steam pipeline 6, steam trap Collector 7, cooling medium circulation system 8, large buffer tank 9, vacuum pump or vacuum unit system 10, drainage pipeline and valve 11, condensate pipe 12, small buffer tank 13, drainage valve 14, return valve 15, dynamic sealing device 16, the material to be dried 17, the support of the rotating cylinder and the driving system 18, 19 the base of the drying chamber is combined, the direction of rotation of the drying chamber 20, the Pt100 thermal resistance temperature sensor (transmitter) 21, the temperature controller 22, the power adjustment device or relay group 23.

[0010] The diameter and length of the rotary cylinder 1 are determined by the volume of the dried material in each batc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com