Epoxy composite of semi-solidified sheet and its use

A technology of epoxy resin and prepreg, applied in epoxy resin glue, adhesive type, chemical instrument and method, etc., can solve the problems of poor construction, low glass transition temperature, poor dimensional stability, etc. Hydrophobicity and insulation, overcoming the effect of low heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The epoxy resin composition is prepared according to the following component ratio (mass ratio):

[0018] The proportions of the composition are as follows:

[0019] Brominated bisphenol A type epoxy resin 79.99%, bromine content 20%, epoxy equivalent 400-450;

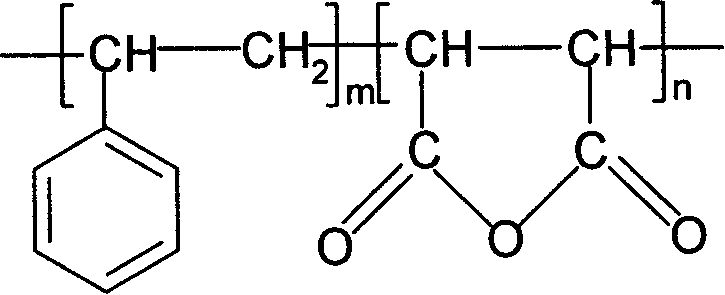

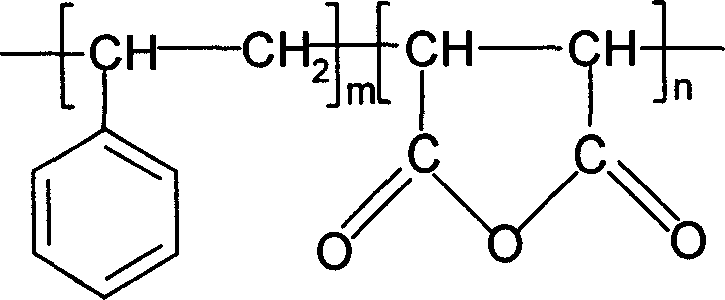

[0020] Styrene-maleic anhydride copolymer (SMA) 10%, weight average molecular weight (MW) = 1,300; maleic anhydride (mass percentage) in SMA copolymer 15.5%; m: n = 4: 1;

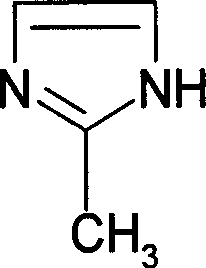

[0021] Accelerator 2-methylimidazole 0.01%;

[0022] The solvent is 10% of the mass of the composition.

[0023] The laminate production process is as follows:

[0024] Epoxy resin and styrene-maleic anhydride copolymer (SMA) added in a certain proportion are dissolved with an appropriate amount of dimethylformamide (DMF) as a solvent, and then 0.01% 2-methylimidazole is added as a curing accelerator to fully Stir evenly to make resin glue, stir for 1 hour, and the gel time measured by a gel time tester is 200s / 170°C.

[0025] Immerse th...

Embodiment 2

[0027] This epoxy resin mixture is prepared according to the following component ratio (mass ratio):

[0028] The proportions of the composition are as follows:

[0029] Brominated bisphenol A type epoxy resin 50%, bromine content 20%, epoxy equivalent 400-450;

[0030] Styrene-maleic anhydride copolymer (SMA) 36%, weight average molecular weight (MW)=10,000; Maleic anhydride (mass percentage composition) 18% in SMA copolymer; m: n=4: 1;

[0031] The accelerator 2-methylimidazole is 4%; the solvent is 10% of the mass of the composition.

[0032] The production process of this laminated board is as embodiment 1. The laminate has good thermal stability, with a Tg of about 175°C (measured by DSC), and when the resin content of the substrate is more than 40%, its dielectric constant (εr) and dielectric loss (tanδ) are: 4.0 and 0.01 or less.

Embodiment 3

[0034] The epoxy resin composition is prepared according to the following component ratio (mass ratio):

[0035] The proportions of the composition are as follows:

[0036] Brominated phenolic resin epoxy resin 10%, bromine content 19%, epoxy equivalent 400-430;

[0037] Styrene-maleic anhydride copolymer (SMA) 74%, weight average molecular weight (MW)=50,000; Maleic anhydride (mass percentage composition) 17.5% in SMA copolymer; m: n=4: 1;

[0038] The accelerator 2-methylimidazole is 6%; the solvent is 10% of the mass of the composition.

[0039] The production process of this laminated board is as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com