Negative photosensitive composition and negative photosensitive lithography plate

A photosensitive composition and negative-type technology, applied in lithographic printing equipment, printing, printing technology, etc., can solve the problems of reduced sensitivity and poor storage stability, and achieve high sensitivity, excellent printing resistance, and excellent storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0192] As shown in the compounding table of Table 1, 0.2 g (2% by mass) of near-infrared-absorbing cationic dye (A) represented by the following formula (A) (manufactured by Showa Denko, IRT) as (A) infrared absorbing agent 0.6 g (0.6% by mass) of an organoboron compound (B1) represented by the following formula (B1) (manufactured by Showa Denko, P3B) as (B) an organoboron compound, and the above-mentioned [Chem. 15] as a salt 0.9 g (9 mass %) of the indicated salt (manufactured by Wako Pure Chemical Industries, Ltd.), 3.0 g (30 mass %) of dipentaerythritol hexaacrylate (manufactured by Nippon Kayaku) as (C) a compound having a polymerizable unsaturated group ), as (D) binder resin, 4.8 g (48 mass %) of the above-mentioned binder resin (D1), as a surfactant, DC-190 (10%, ethylene glycol monomethyl ether solution, i 0.2 g of ストトマンコダツクカソパニニ) and 0.3 g of crystal violet (manufactured by Hodo Ketani Chemical Co., Ltd.) as a coloring material were dissolved in a solvent consist...

Embodiment 2-5

[0199] [Example 2-5, Comparative Example 1-2]

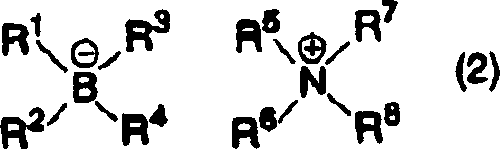

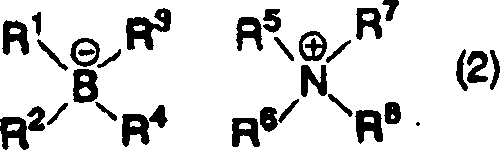

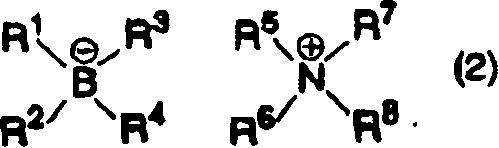

[0200] Except having changed the compounding of the coating liquid like Table 1, it carried out similarly to Example 1, the negative photosensitive planographic printing plate was produced, and it evaluated. Table 2 shows the evaluation results. Here, the organoboron compound (B2) in Table 1 is a compound (manufactured by Showa Denko, NP3B) represented by the following formula (B2), and the salt (2) is the salt represented by the following formula (2) ( manufactured by Wako Pure Chemical Industries, Ltd.), and the salt (3) is a salt represented by the following formula (3) (manufactured by Wako Pure Chemical Industries, Ltd.).

[0201] Element

[0202] [chemical 19]

[0203]

[0204] [chemical 20]

[0205]

[0206] [chem 21]

[0207]

[0208] [chem 22]

[0209]

[0210] [chem 23]

[0211]

[0212] [chem 24]

[0213]

[0214]

[0215] It is clear from the results in Table 2 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com