Method for synthesizing reactive yellow DF 3RS

A technology of DF-3RS and synthesis method, which is applied in the field of chemical synthesis of dyes, can solve problems such as increasing costs, achieve the effects of reducing raw material costs, eliminating sewage discharge, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

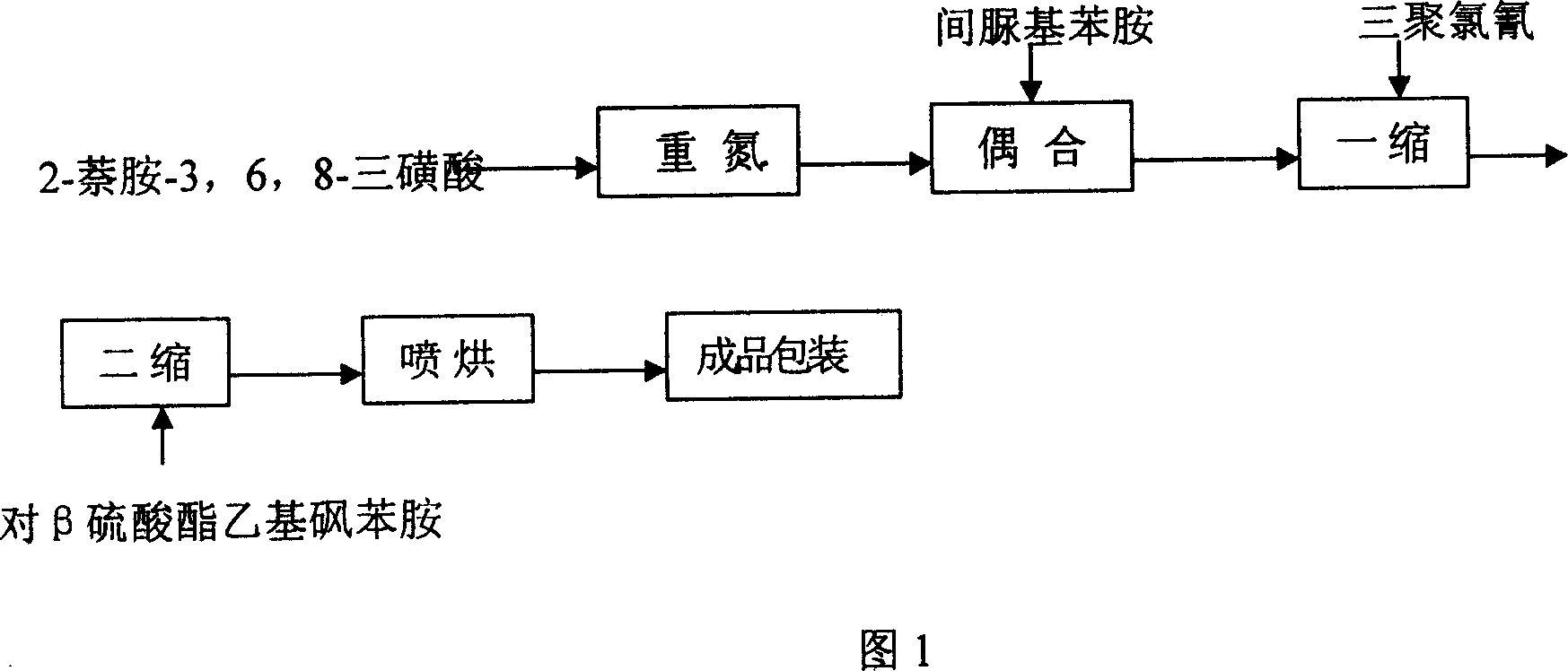

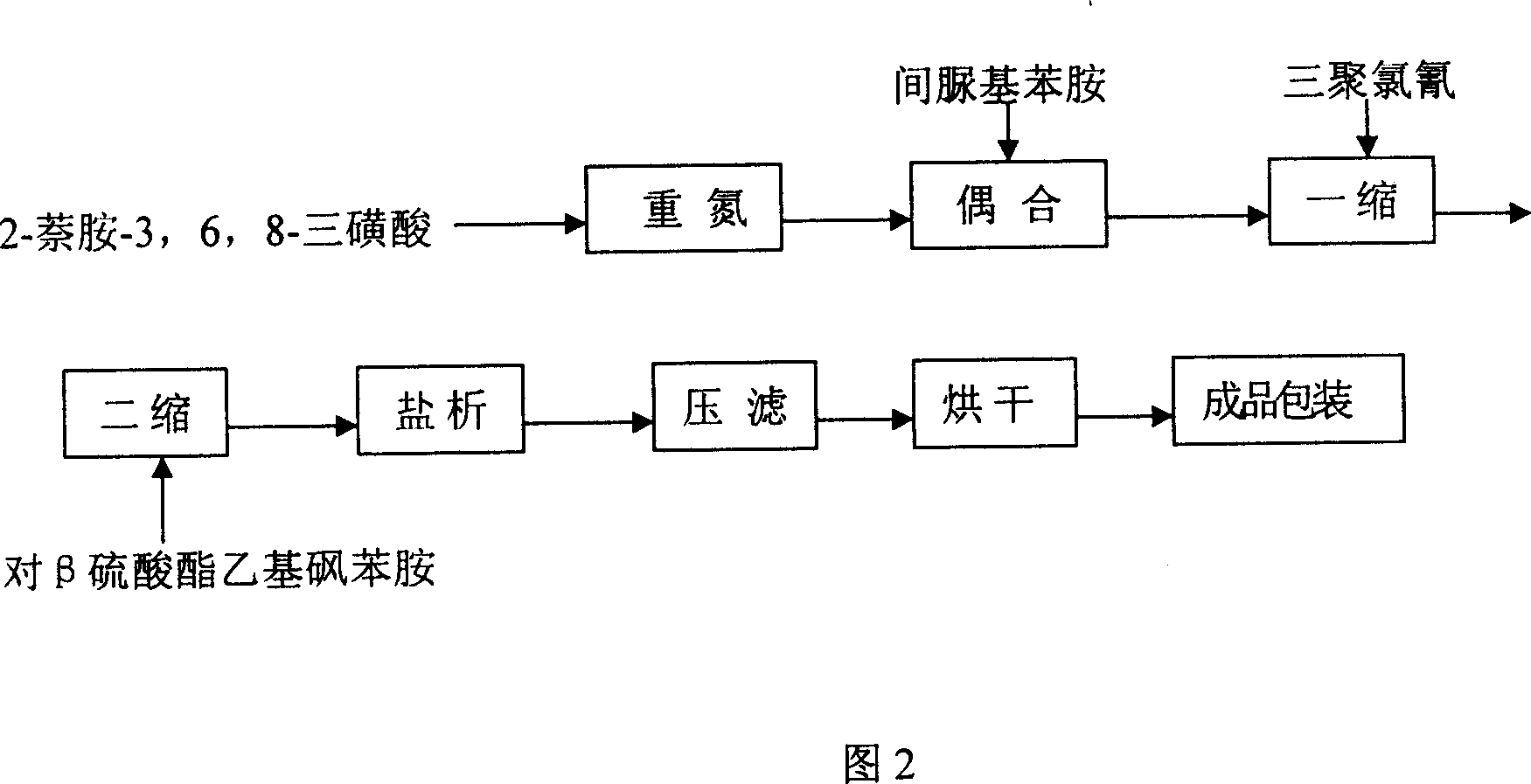

Method used

Image

Examples

Embodiment 1

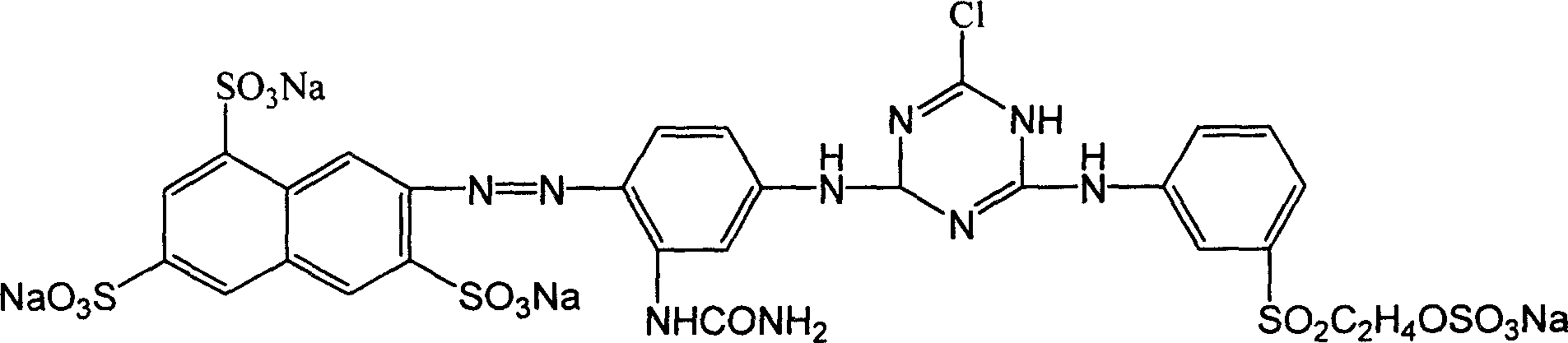

[0053] The synthetic method of reactive yellow DF-3RS of the present invention operates as follows:

[0054] A. Diazo:

[0055] Put 2000L of bottom water, weigh 299kg of 2-naphthylamine-3,6,8-trisulfonic acid, put into beating for 1.5h, add ice, add HCl 28.5kg, temperature T=5℃, add NaNO 2 After adding the solution, keep the KI test paper microscopic blue, and react for 2 hours.

[0056] B. Coupling:

[0057] Put 400L of ice water, throw in 117.8kg of ureidoaniline, beat for 1 hour, add 80kg of NaCO 3 Stir for 10 minutes, put the diazonium solution in step A into the coupling barrel, keep the pH=4, the temperature is 6°C, react for 3h, then adjust the pH=9.5 with soda water, and react for 1.2h to reach the end point.

[0058] C. One condensation:

[0059] Put 200L of bottom water, add ice and put 150kg of cyanuric chloride into ice grinder for beating for 1 hour at 0°C, add the coupling liquid in Step B that has reached the end point into the cyanuric chloride suspe...

Embodiment 2

[0067] A. Diazo:

[0068] Put 2000L of bottom water, weigh 284.1kg of 2-naphthylamine-3,6,8-trisulfonic acid, put it into beating for 2h, add ice, add HCl 29.9kg, temperature T=5℃, add NaNO 2solution, equivalent to NaNO 2 56.5kg, after adding, keep the KI test paper micro-blue, and react for 1h.

[0069] B. Coupling:

[0070] Put 400L of bottom water, throw in 123.7kg of ureidoaniline, beat for 1 hour, add 80kg of NaCO 3 Stir for 10 minutes, put the diazonium solution in step A into the coupling barrel, keep the pH=4, temperature 6°C, react for 1h, then adjust the pH=9 with aqueous sodium carbonate solution, and react for 1h to reach the end point.

[0071] C. One condensation:

[0072] Put 200L of bottom water, add ice and put 156.4kg of cyanuric chloride into ice grinder for beating at 0°C for 1 hour, add the coupling solution in Step B that has reached the end point into the cyanuric chloride suspension within 1 hour, and use soda ash after the addition is completed. A...

Embodiment 3

[0080] A. Diazo:

[0081] Put 2000L of bottom water, weigh 314.0kg of 2-naphthylamine-3,6,8-trisulfonic acid, put it into beating for 1.5h, add ice, add HCl27.1kg, temperature T=5℃, add NaNO 2 solution, equivalent to NaNO 2 51.1kg, after adding, keep KI test paper microscopic blue, and react for 4h.

[0082] B. Coupling:

[0083] Put 400L of bottom water, throw in 111.9kg of ureidoaniline, beat for 1 hour, add 80kg of NaCO 3 Stir for 10 minutes, put the diazonium solution in step A into the coupling barrel, keep the pH=4.5, temperature 7°C, react for 5h, then adjust the pH=10 with aqueous sodium carbonate solution, and react for 1.5h to reach the end point.

[0084] C. One condensation:

[0085] Put 200L of bottom water, add appropriate amount of ice, put 142.0kg of cyanuric chloride into ice grinder for beating at 0°C for 1 hour, add the coupling solution in Step B that has reached the end point into the cyanuric chloride suspension within 1 hour, and add it in about 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com