Flexible curtain wall, and aero amphibious preparation, method for continuous laying it in unlimited water area

A water barrier, sea, land and air technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of low construction speed and efficiency, incapable of mechanized manufacturing and laying, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

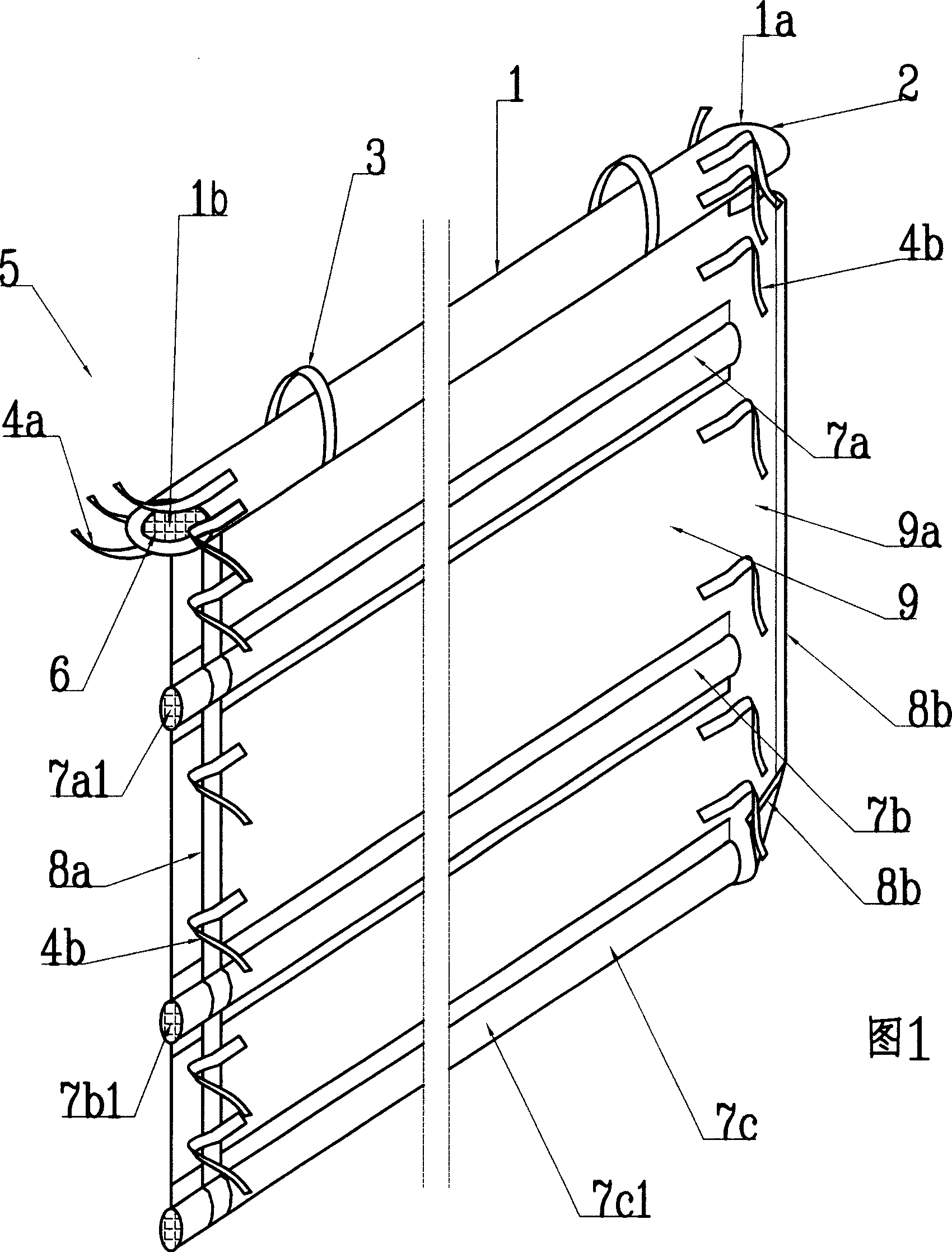

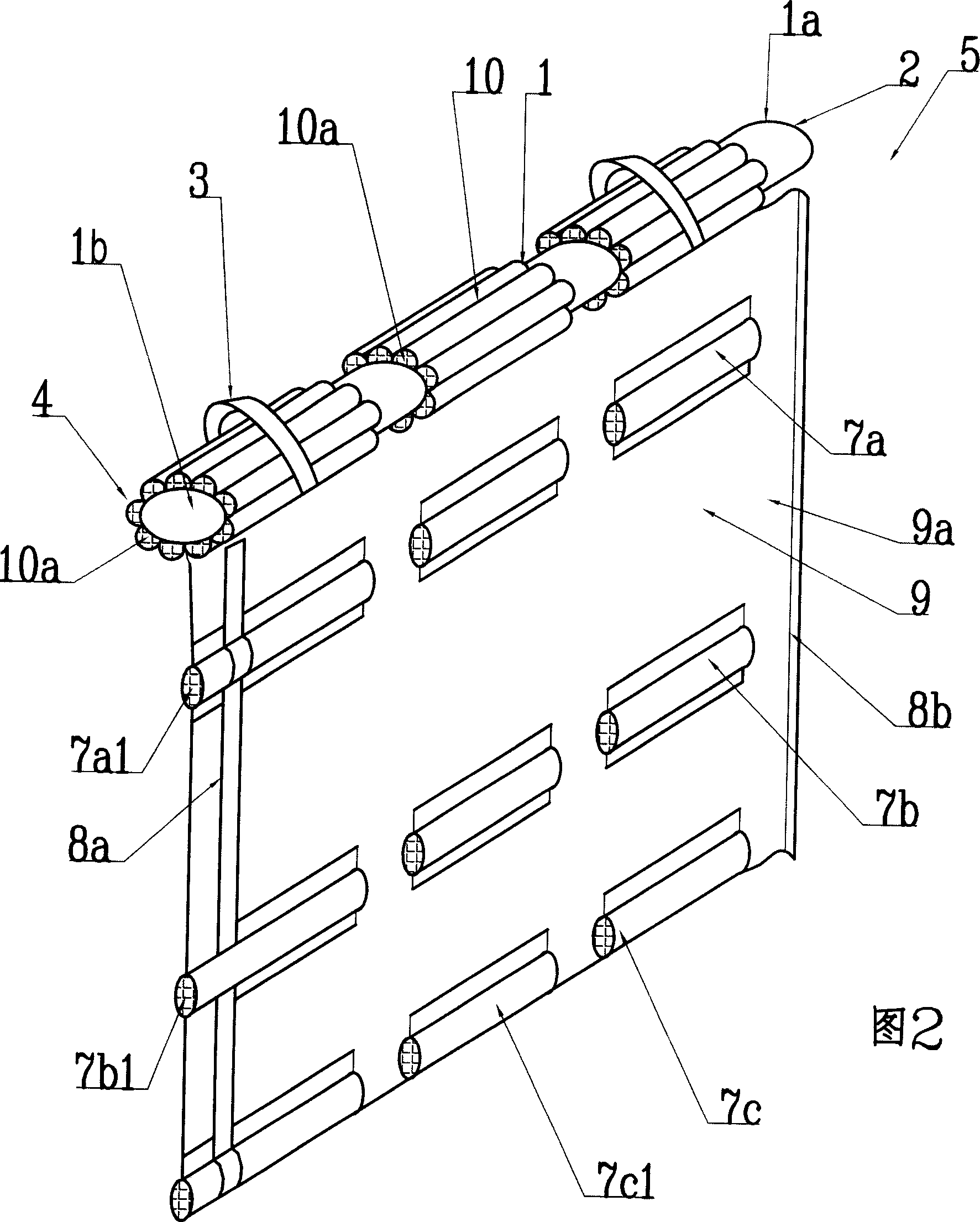

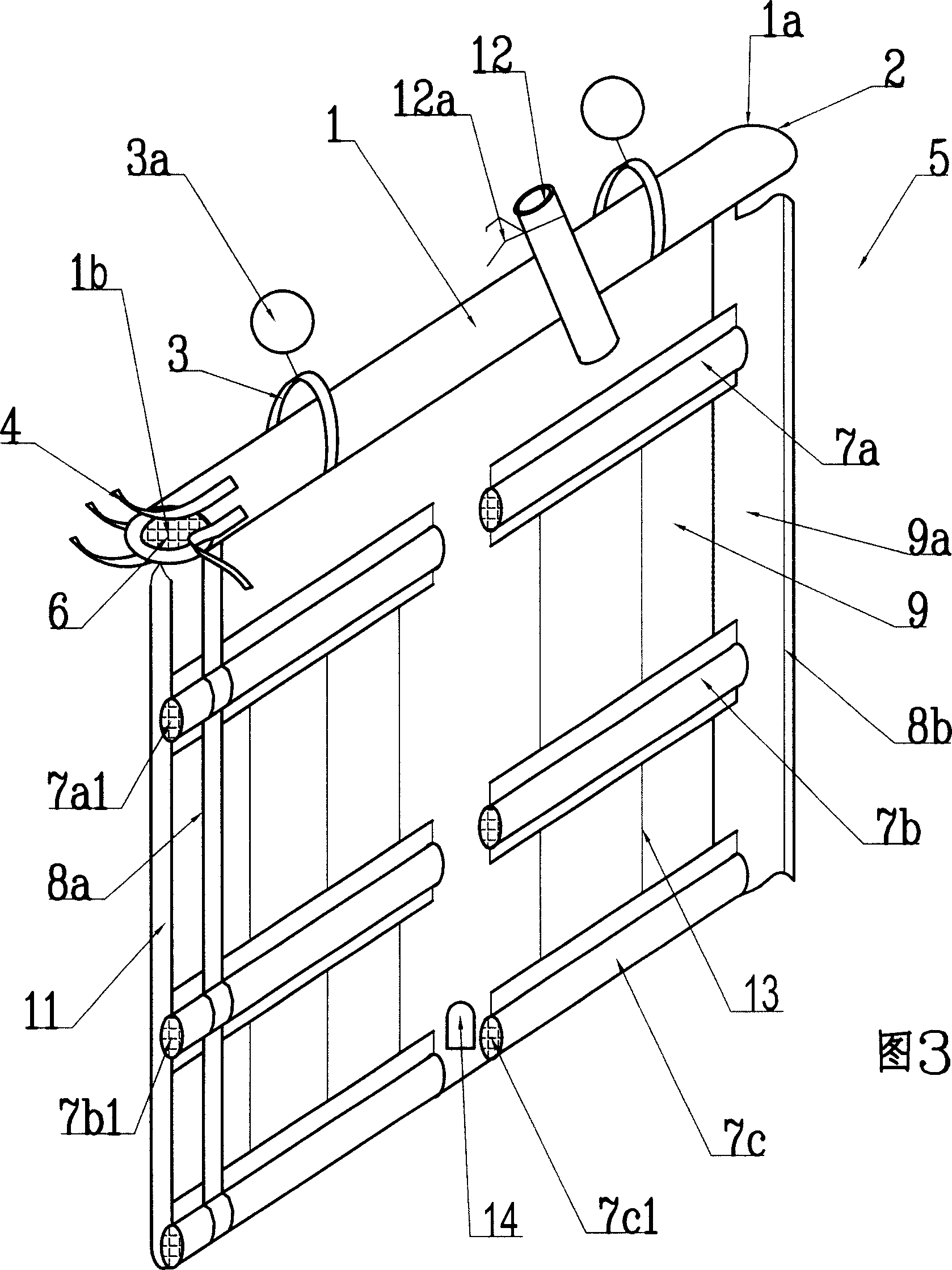

[0058] This water barrier includes floating body header 1, curtain wall body 9, hook and loop 8, lifting lug 3, transverse rib belt 7 and connectors; this water barrier is provided with a floating body header 1, and the floating body header 1 is made of aramid fiber cloth , the axis of the floating body header 1 on the upper part of the curtain wall body is parallel to the horizontal line, and the nozzle 2 of the floating body header 1 is filled with polyurethane foam material 6 with a specific gravity less than 1, and the lower part of each floating body header 1 is connected to a curtain wall body 9; The curtain wall body 9 is made of aramid fiber cloth; three axis-level transverse ribs 7a, 7b and 7c are arranged on the curtain wall body, the transverse rib bands are made of aramid fiber cloth, and the two sides of the transverse rib bands are sewn on the curtain wall body; the transverse rib bands of the curtain wall body 7b and 7c are respectively filled with solidified soi...

Embodiment 5

[0078] In this embodiment, the water partition wall manufacturing assembly described in Embodiment 1 is arranged on the engineering vehicle 48 for land operation, processed and manufactured in the engineering vehicle on site, and then directly laid in the infinite waters with a boat; this method is The engineering vehicle 48 is fixed, and the finished water partition wall is thrown behind the engineering vehicle 48 under the traction power guide wheel mechanism 31, and the head end of the infinitely long water partition wall 5 is anchored on the auxiliary operation ship by fasteners 56 , the auxiliary operation ship is towed forward in the polluted water area 55 water bodies, and the infinitely long water barrier is continuously thrown into the water body through the swingable roller mechanism and unfolded by itself, completing the continuous production and laying in the infinite water area emergency The water barrier; the ship's swingable idler mechanism 57 is the same as that...

Embodiment 6

[0081] In this method, the head end of the completed infinitely long water partition wall is anchored on the substrate 41 in the water body by using the connector 42, and the engineering vehicle is continuously dropped into the water body along with the infinitely long water partition wall. 54 or the shore, and the auxiliary operation ship 34 also walks in parallel with the embankment 54 or the bank in the water body. middle.

[0082] Shown in Fig. 10 and 12 is that the overall structure of the bulkhead of embodiment 1 is made on the spot in the transport cabin of helicopter transport aircraft, the embodiment 6 of the method for directly laying continuously over infinite waters;

[0083] This method needs to arrange the water partition wall production assembly in the transport cabin of the helicopter transport aircraft; the head end of the infinitely long water partition wall is thrown into the water body on the heavy object anchored by cables, and the water partition wall after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com