Stepping motor

A technology of stepping motors and rotating shafts, applied in the field of screw rods, can solve the problems of self-starting frequency and drop that have not been raised, and achieve the effects of improving motor characteristics, reducing inertial loads, and preventing the decline of the maximum self-starting frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

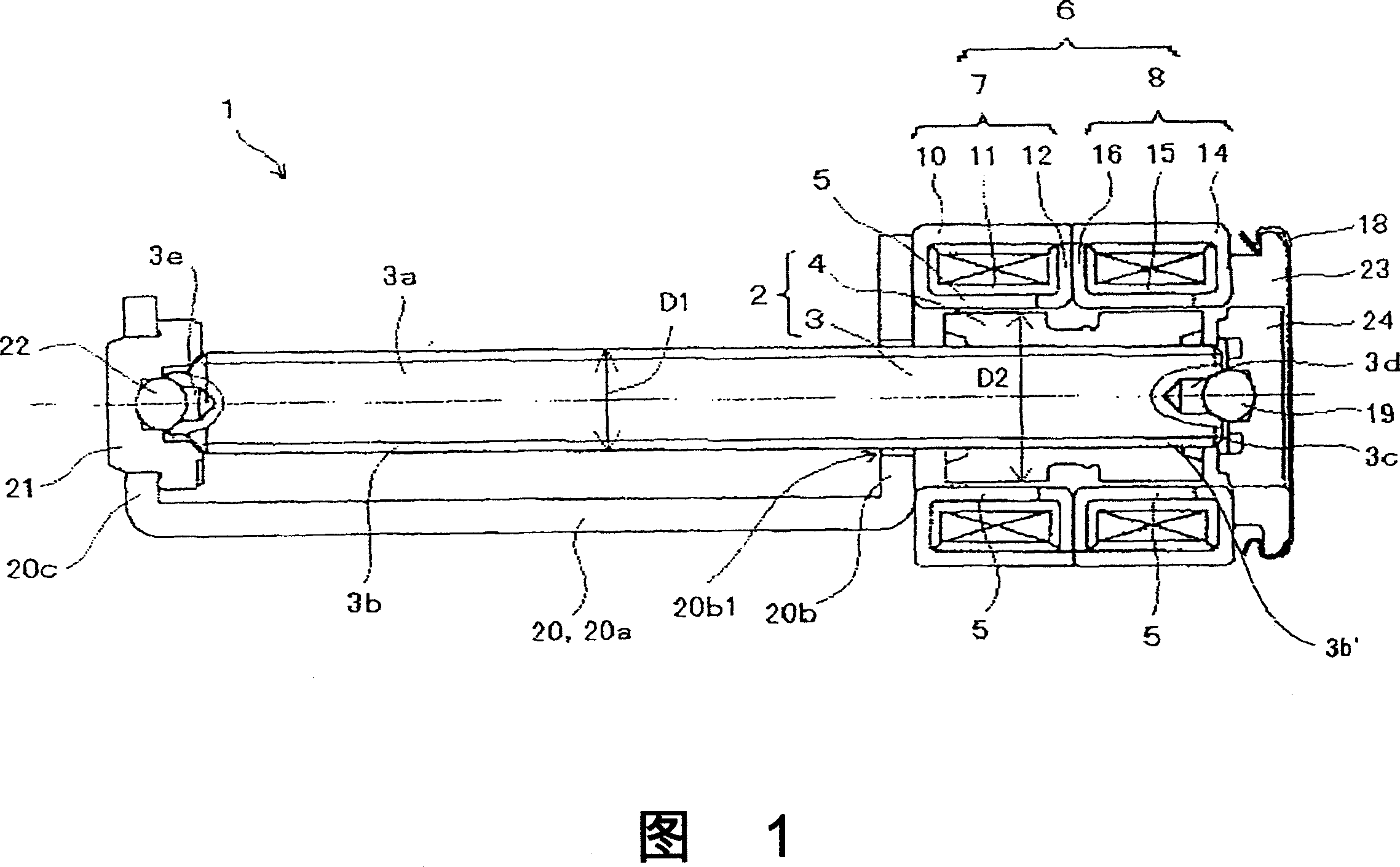

[0049] Fig. 1 is a side sectional view showing a stepping motor according to an embodiment of the present invention.

[0050] (Structure of stepping motor)

[0051] The stepping motor 1 of this form is a so-called PM-type stepping motor, and has a rotor 2, a stator 6 and a frame 20, and the rotor 2 has a rotating shaft 3 and a cylindrical permanent magnet 4, and the stator 6 has a radial direction. The pole teeth 5 opposite to the permanent magnets 4 , the frame 20 are on the output side of the rotating shaft 3 and mounted on the stator 6 . Further, on the output side of the rotary shaft 3, an output shaft 3a protruding from the stator 6 is integrally formed, and a screw part 3b is formed on the output shaft 3a. In addition, a bearing holding member 23 is attached to the opposite output side of the stator 6 (the base end 3 c side of the rotating shaft 3 ), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com