Production method of acryl plate with inner layer pattern paper

A technology of acrylic sheet and manufacturing method, applied in the direction of lamination, lamination device, chemical instrument and method, etc., can solve the problems of inability to make finished products, layer peeling, detachment, damage, simple color change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

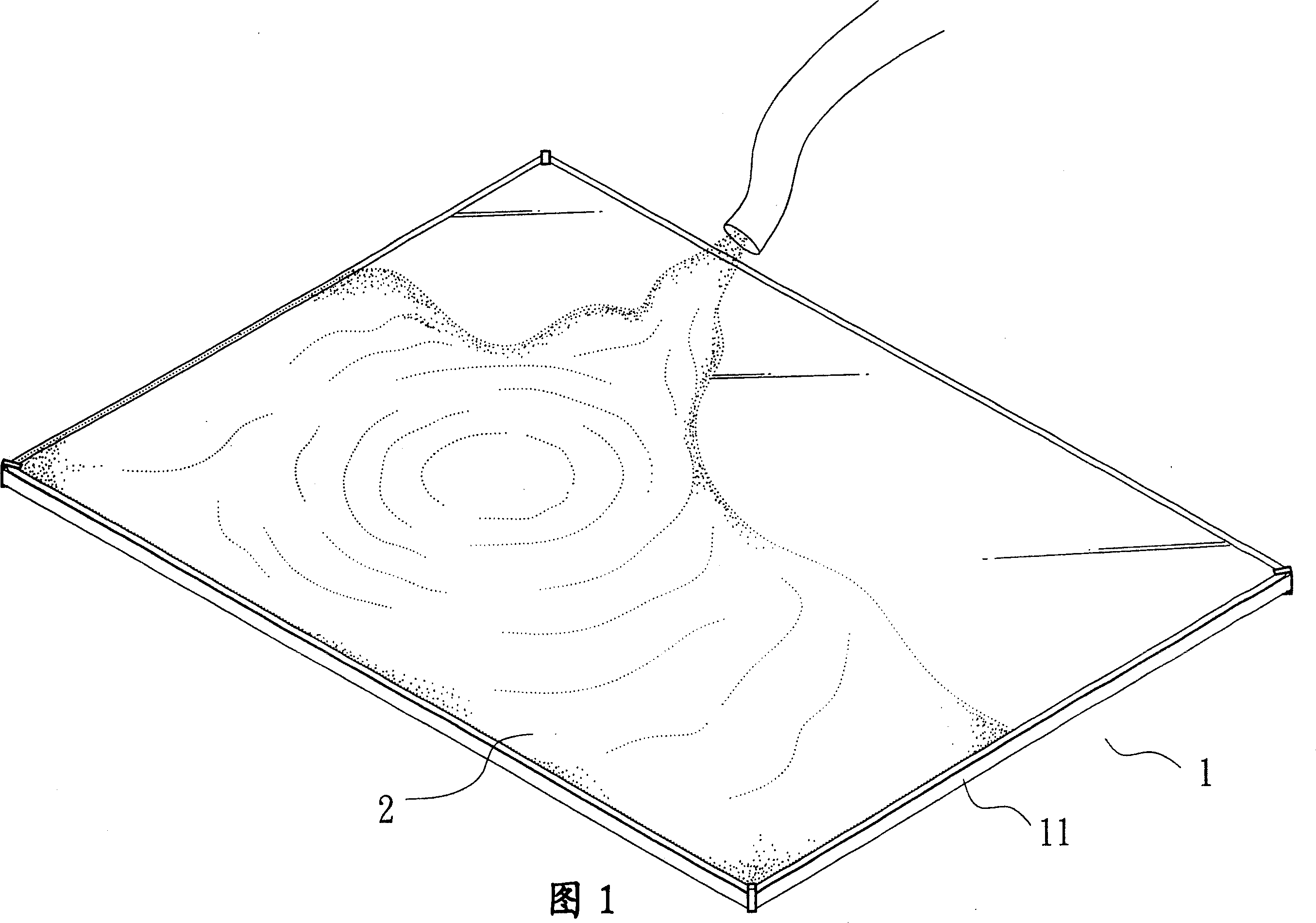

[0022] First, please refer to FIG. 1 , the present invention pours acrylic raw materials into the lower mold part 11 of the mold 1 to form a first layer of acrylic plate 2 in the lower mold part 11 .

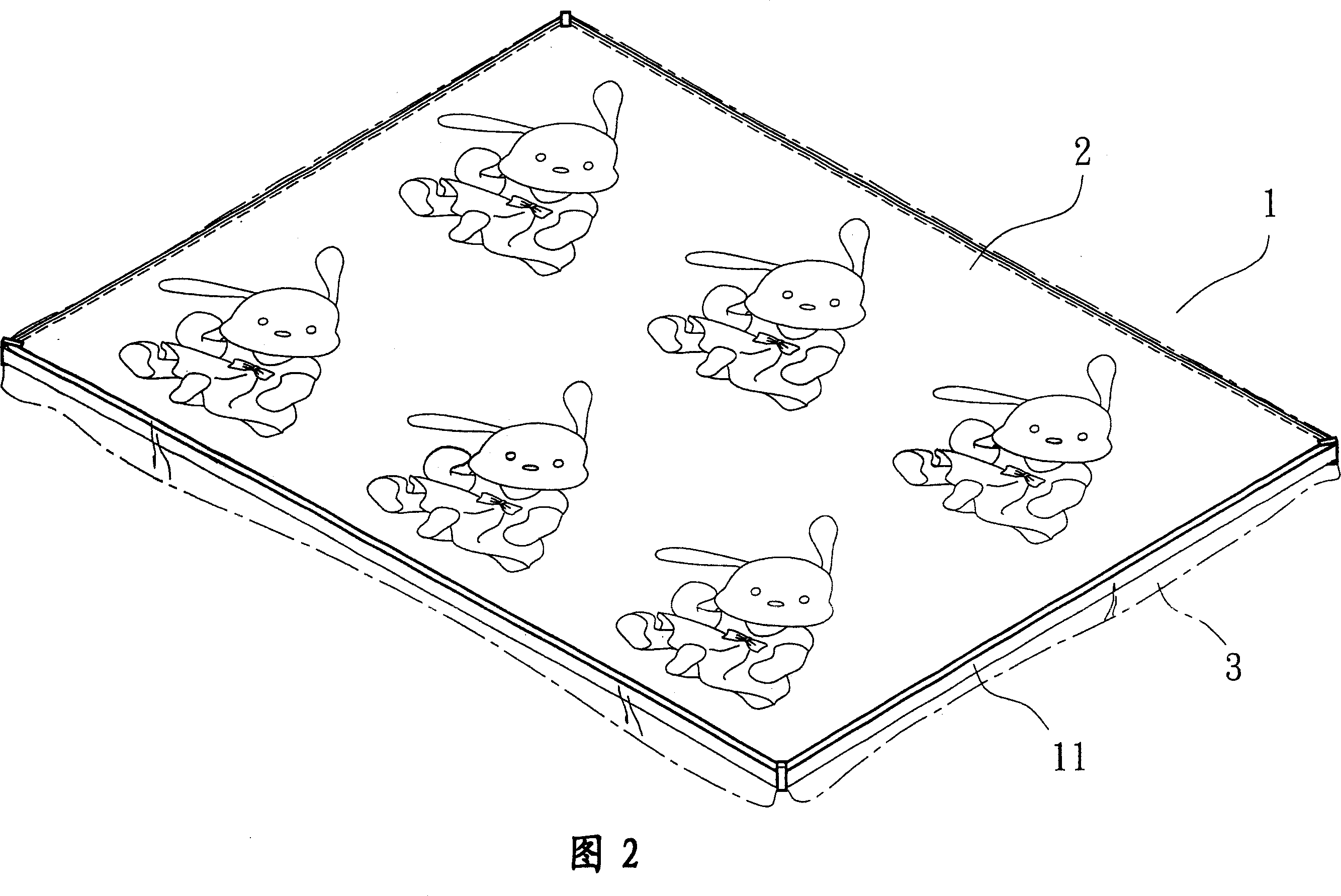

[0023] As shown in Fig. 2 again, above the first layer of acrylic plate 2 in the lower mold part 11 of the mold 1, the ink with characteristics such as heat resistance, fixation, high temperature resistance and light resistance is printed on one side or double side. Masking people, things, objects or landscapes...etc. cold zone fiber mirror copper kraft paper pattern paper3.

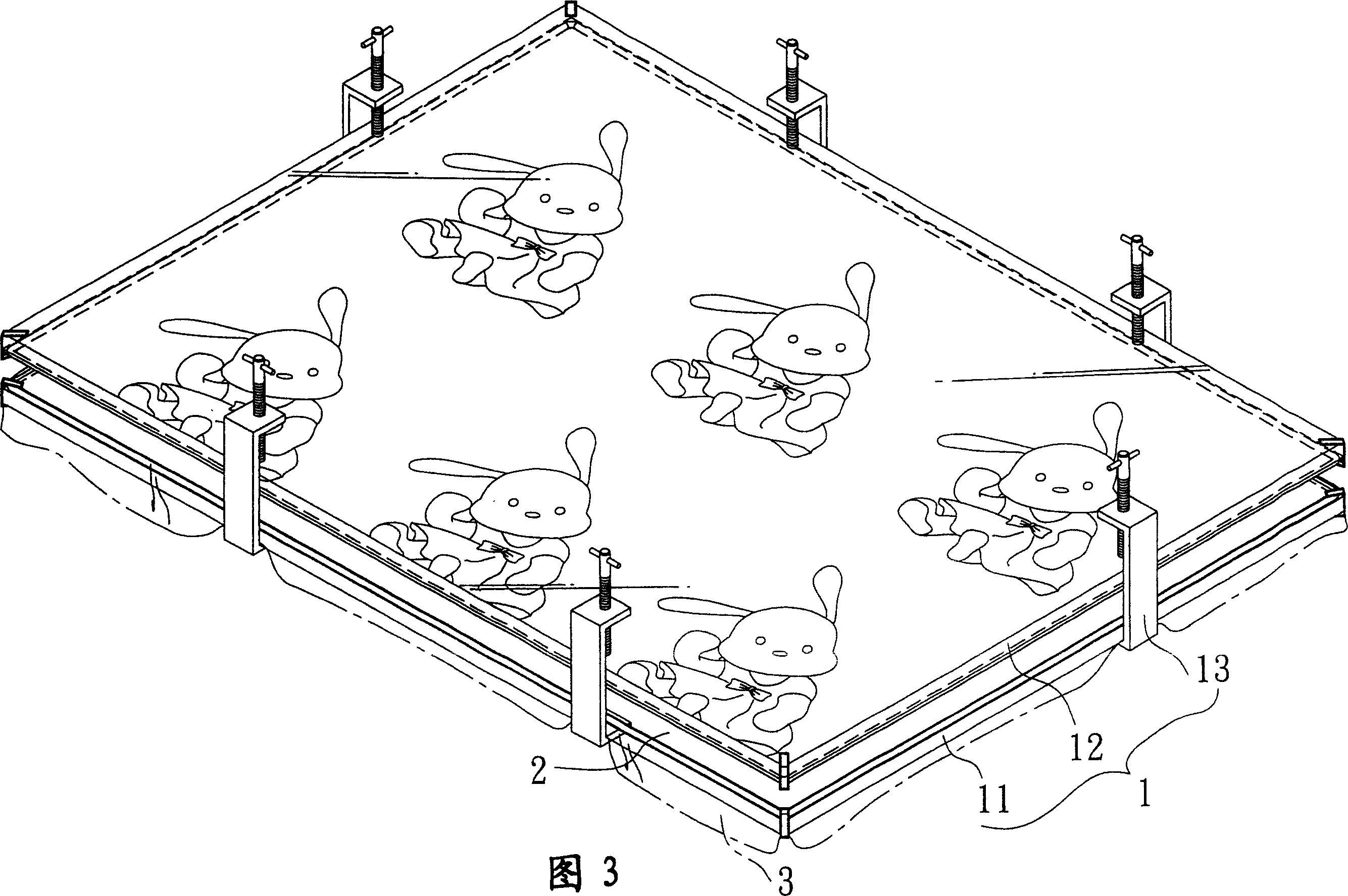

[0024] As shown in Figure 3 again, the upper mold part 12 is clamped on the lower mold part 11 of the mold 1, and the lower and upper mold parts 11, 12 are clamped and fixed by the clamping member 13 so that it will not move and fall off.

[0025] Finally, as shown in Figure 4, pour acrylic raw materials into the upper mold part 12 of the mold 1 to form a second layer of acrylic plate 4 in the upper mold p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com