Split type omnibearing take-over laser booster

An all-round and separate technology, which is applied in the direction of combustion method, aerospace vehicle propulsion system device, combustion ignition, etc., can solve the problems of energy loss, limited adjustment range, and failure of optical mirror, so as to achieve small light loss and reduce development The effect of cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

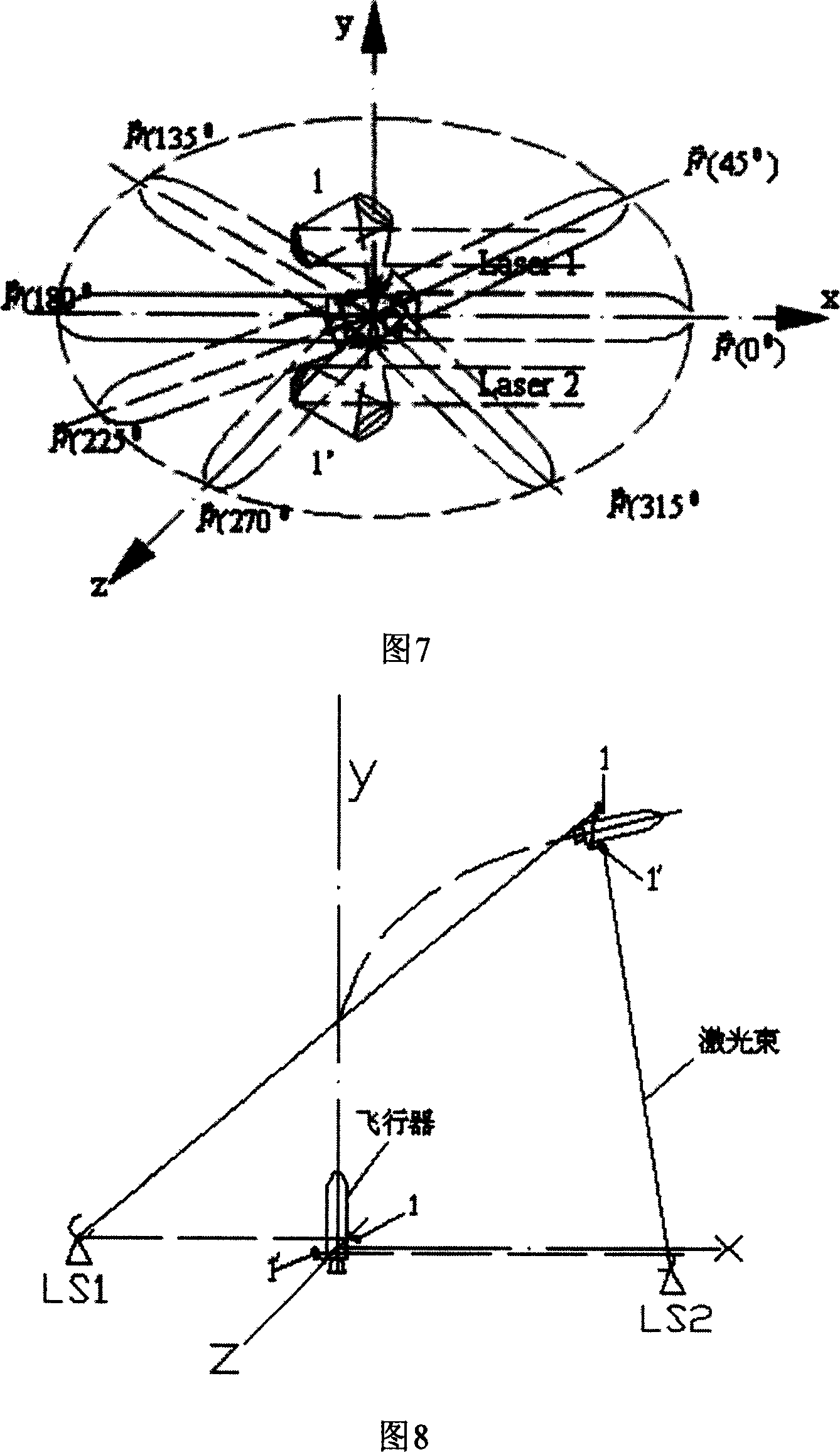

[0027] The present invention has three structural forms, the structure adopting a single beam engine, the structure adopting a double beam single engine and the structure adopting a double beam dual engine, which will be described in detail below.

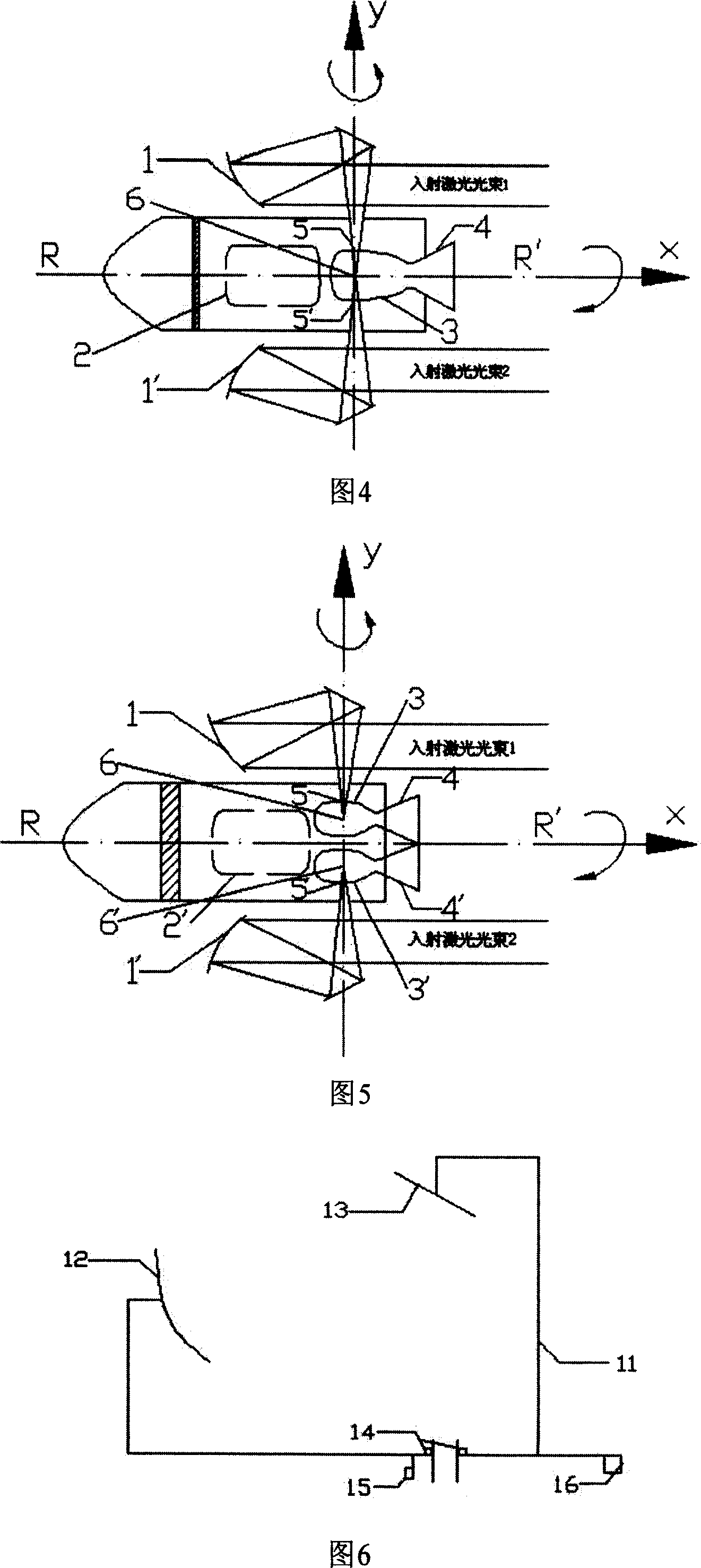

[0028] As shown in Figure 3, it is the thruster that adopts single-beam engine structure of the present invention, and it is made up of optical system 1, propellant tank 2, combustion chamber 3 and nozzle 4, and optical system 1 is positioned at the outer side of combustion chamber 3 , and is connected with the solid body of the rocket body. There is a transparent circular laser incident window 5 on the combustion chamber 3. The optical system 1 rotates around the laser incident window to receive all the laser beams in the xz plane. When the laser beam passes through the When the laser incident window 5 is concentrated and incident on the center position 6 of the combustion chamber 3, the propellant in the combustion chamber is igni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com