Surface quenching process based on grinding

A surface quenching and grinding technology, applied in the field of surface quenching process based on grinding and grinding and hardening processing technology, can solve problems affecting the uniformity of the depth of the hardened layer on the surface of the workpiece, resource and energy consumption, ecological environment pollution, and increase heat treatment. Equipment and personnel investment, etc., to achieve the effect of reducing the investment in heat treatment equipment and personnel, reducing processing procedures, and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

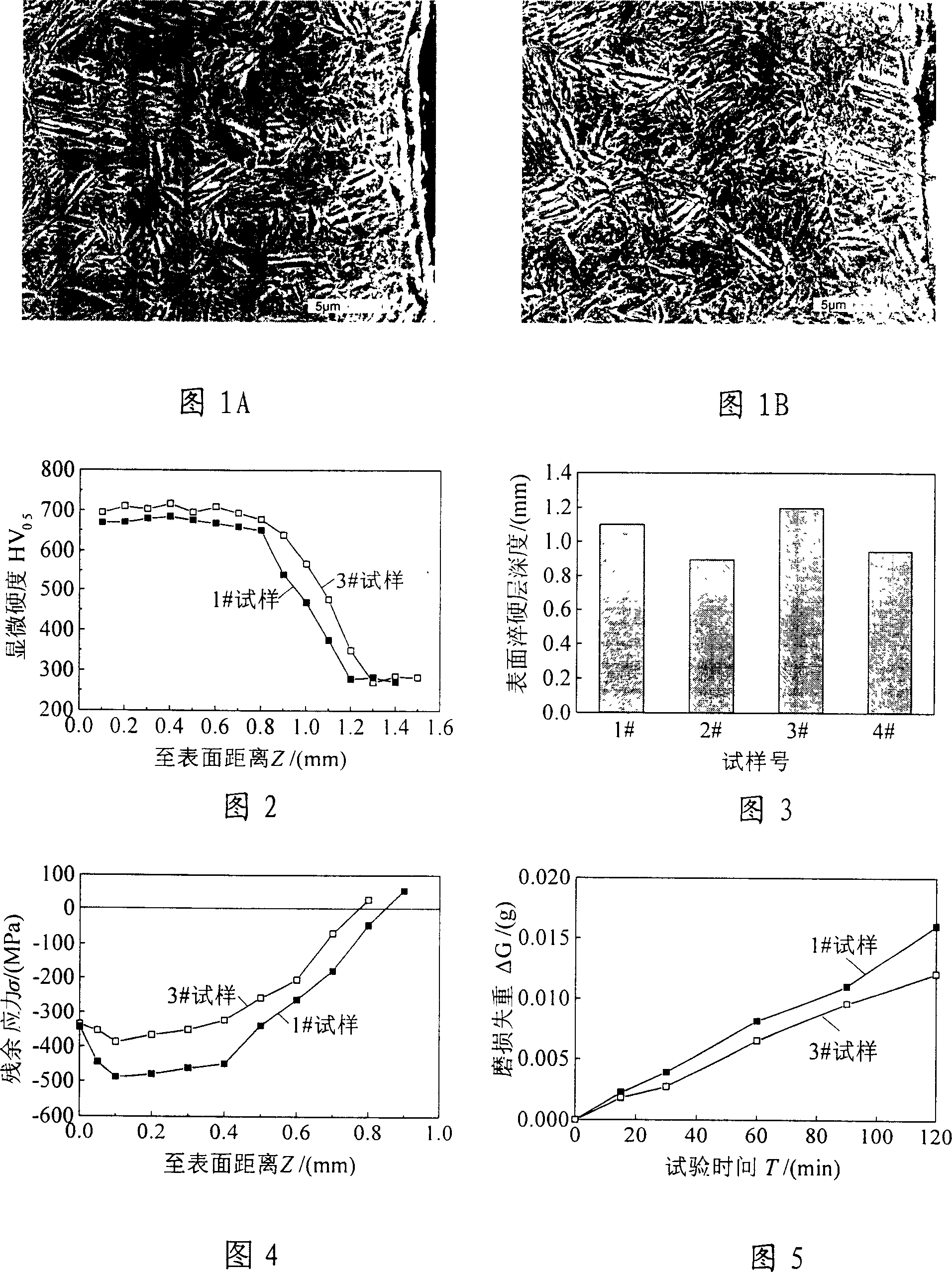

[0028] The surface is hardened by double-pass reciprocating grinding, the grinding speed is 26.3m / s, the grinding depth is 0.5mm, the workpiece feed speed is 1.3m / min, and the cooling method is air cooling.

Embodiment 2

[0030] The surface is hardened by double-pass reciprocating grinding, the grinding speed is 20.3m / s, the grinding depth is 0.2mm, the workpiece feed speed is 0.2m / min, and the cooling method is air cooling.

Embodiment 3

[0032] The surface is hardened by double-pass reciprocating grinding, the grinding speed is 34.3m / s, the grinding depth is 1mm, the workpiece feed speed is 1.2m / min, and the cooling method is dry air cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com