Method for observing magnetic domain structure of heat-resisting Nd-Fe-B magnet

A technology of NdFeB and magnetic domains, which is applied in the field of observing the magnetic domain structure of heat-resistant NdFeB magnets, can solve problems such as complex magnetic domain structures, and achieve the effects of easy popularization and application, low cost, and high solution cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

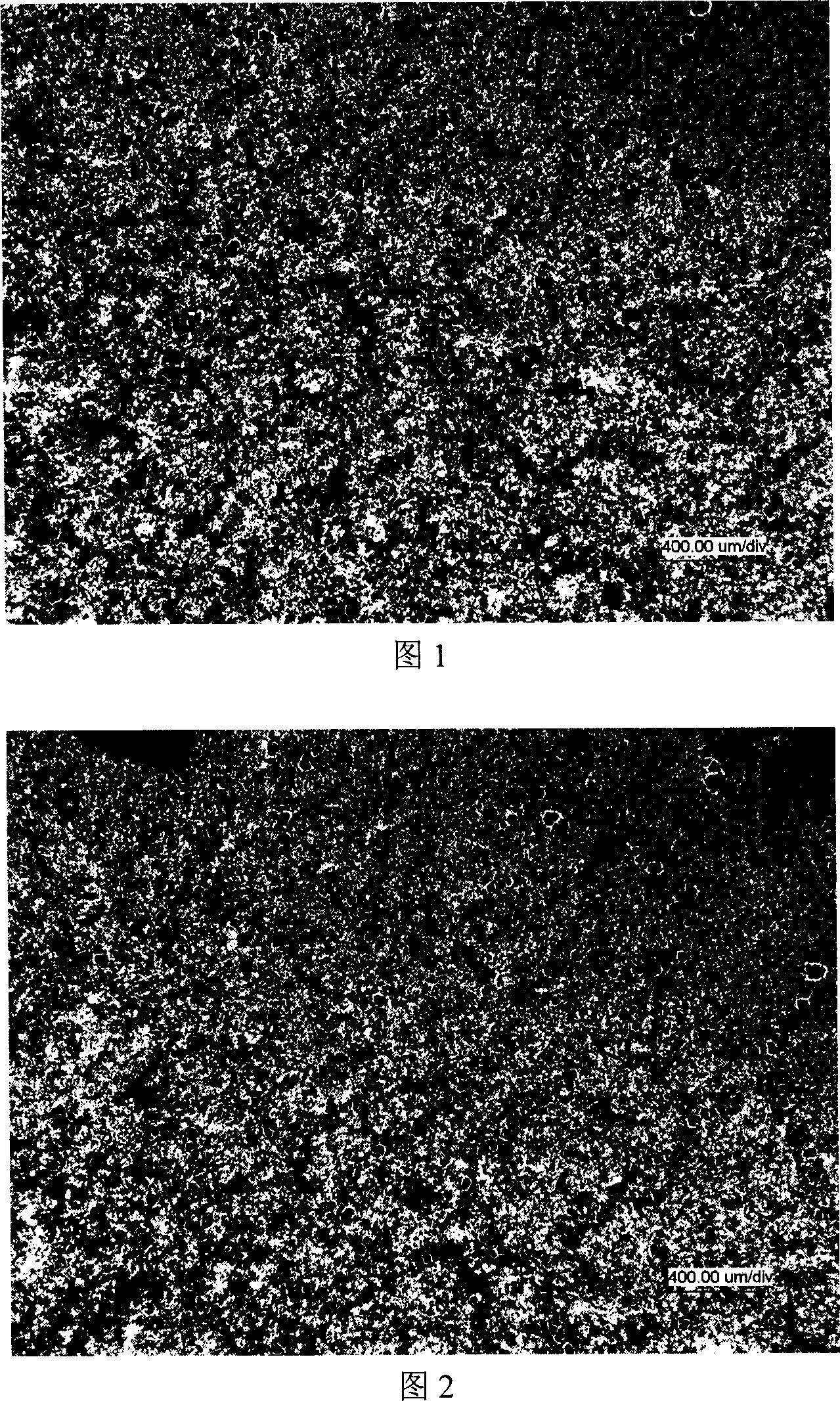

Image

Examples

Embodiment 1

[0022] 2.0g FeCl 2 4H 2 O and 5.3 g FeCl 3 ·6H 2 O was added to distilled water and stirred evenly to form a 280ml solution. Then slowly drop 60ml of NaOH solution with a mass concentration of 10% into the above solution, and stir and filter at 30°C, heat water in the obtained precipitate, stir and filter again, and repeat the filter several times, each time changing New filter paper, get dark brown Fe 3 o 4powder. Add 1.8g of sodium oleate into distilled water, stir evenly, make a 50ml solution, and add an appropriate amount of HCl to make the pH of the solution 7, then add 19ml of Fe 3 o 4 Powder, stir evenly and add appropriate amount of distilled water to dilute to obtain water-based Fe 3 o 4 ferrofluid. Will be observed (Nd 21.6 Dy 4 PR 4 Tb 2 ) 31 Fe 65 (Co 0.96 Nb 0.2 Al 0.2 Cu 0.2 Ga 0.2 ) 2 The sample B is used as the positive electrode after being polished and mechanically polished, and a copper sheet with a larger area than the sample is used a...

Embodiment 2

[0024] 2.2g FeCl 2 4H 2 O and 5.6 g FeCl 3 ·6H 2 O was added to distilled water, and stirred evenly to form a 340ml solution. Then slowly drop 70ml of NaOH solution with a mass concentration of 10% into the above solution, and stir and filter at 40°C, heat water in the obtained precipitate, stir and filter again, and repeatedly filter several times, each time changing New filter paper, get dark brown Fe 3 o 4 powder. Add 2.1g of sodium oleate into distilled water, stir evenly, make a 60ml solution, and add an appropriate amount of HCl to make the pH of the solution 7, then add 22ml of Fe 3 o 4 Powder, stir evenly and add appropriate amount of distilled water to dilute to obtain water-based Fe 3 o 4 ferrofluid. Will be observed (Nd 17.6 Dy 5 PR 6 Tb 3 ) 31 Fe 66 (Co 1.36 Nb 0.1 Al 0.1 Cu 0.1 Ga 0.1 ) The B sample is used as the positive electrode after being polished and mechanically polished, and a copper sheet with a larger area than the sample is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com