Preparing method of block amorphous ring type magnetic core

A toroidal, amorphous technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, inorganic material magnetism, etc. problems such as the influence of working magnetic properties, to achieve the effect of easy implementation, less surface defects, and improved space factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

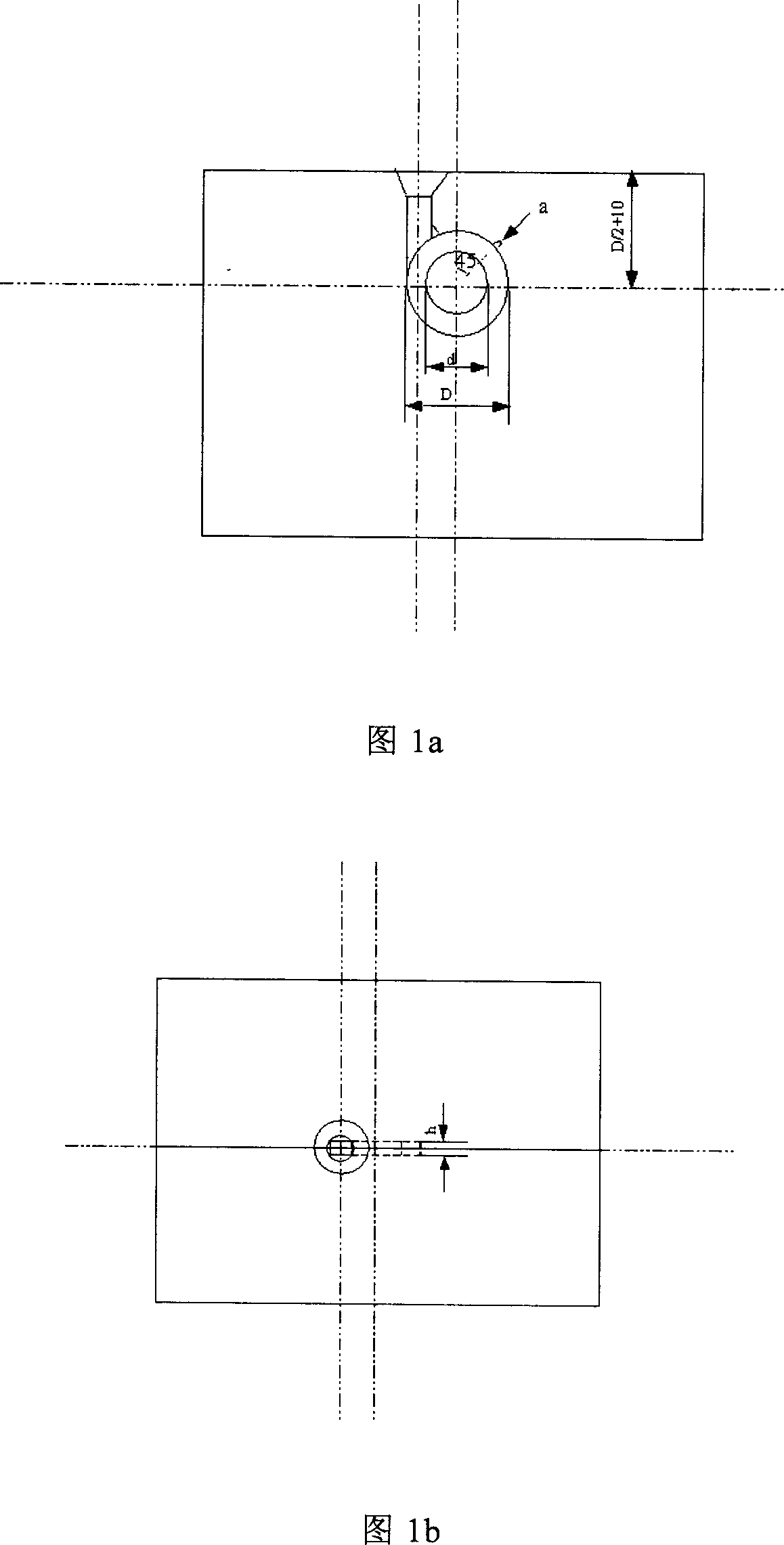

[0011] The preparation method of the present invention is specifically as follows:

[0012] (1) Weigh each element

[0013] Calculate the weight of each element related to it according to the number of atoms required;

[0014] (2) Melting master alloy

[0015] Put the required raw materials weighed in step (1) into the vacuum high-frequency induction smelting furnace, and adjust the vacuum degree to 1~8×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.01-0.08MPa; the current is adjusted to 15-25A, the induction temperature is 1000-1600°C; the melting time is 5-10min, and the master alloy is taken out after cooling with the furnace;

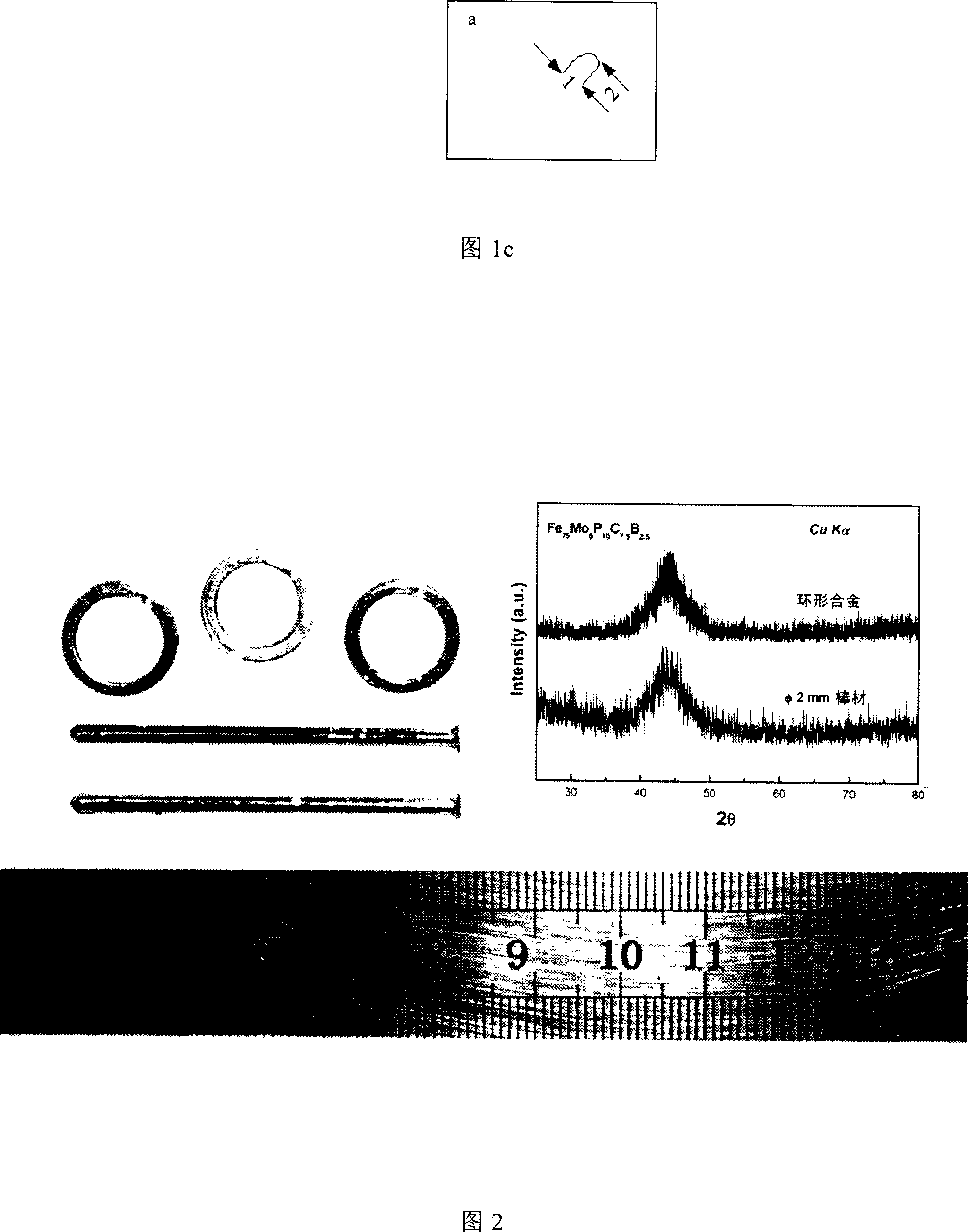

[0016] (3) Ring-shaped bulk amorphous alloy

[0017] Put the master alloy prepared in step (2) into the induction furnace of the rapid solidification device, and adjust the vacuum degree to 1~8×10 -3 Pa, filled with argon protective gas, the pressure of argon is 0.01-0.08MPa; the current is adjusted to 2-10A, the induction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com