Smart card body, manufacturing method thereof, smart card, installation method thereof and belt carrier

A manufacturing method and smart card technology, applied in the field of smart cards, can solve problems such as inflexibility and achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

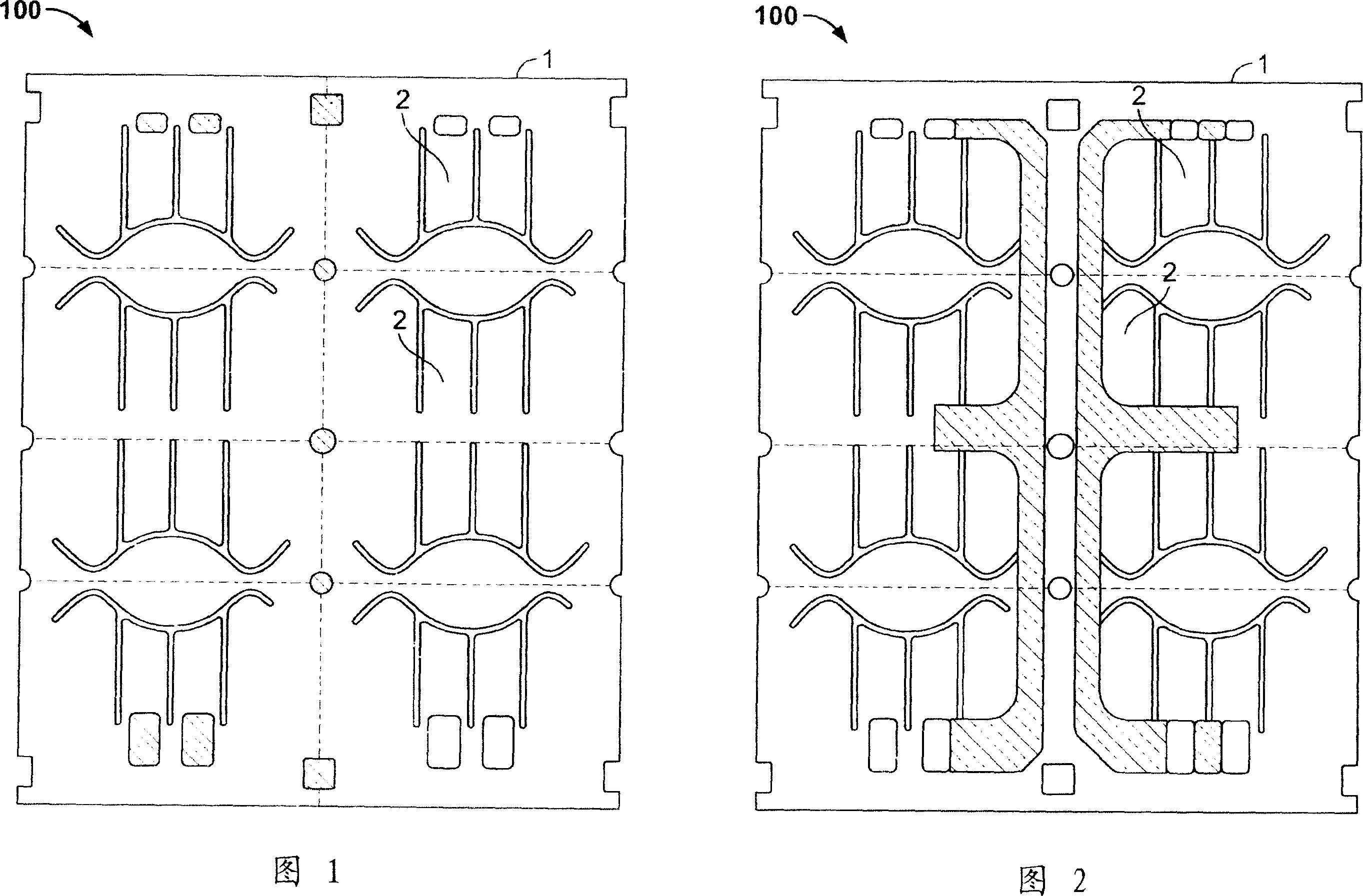

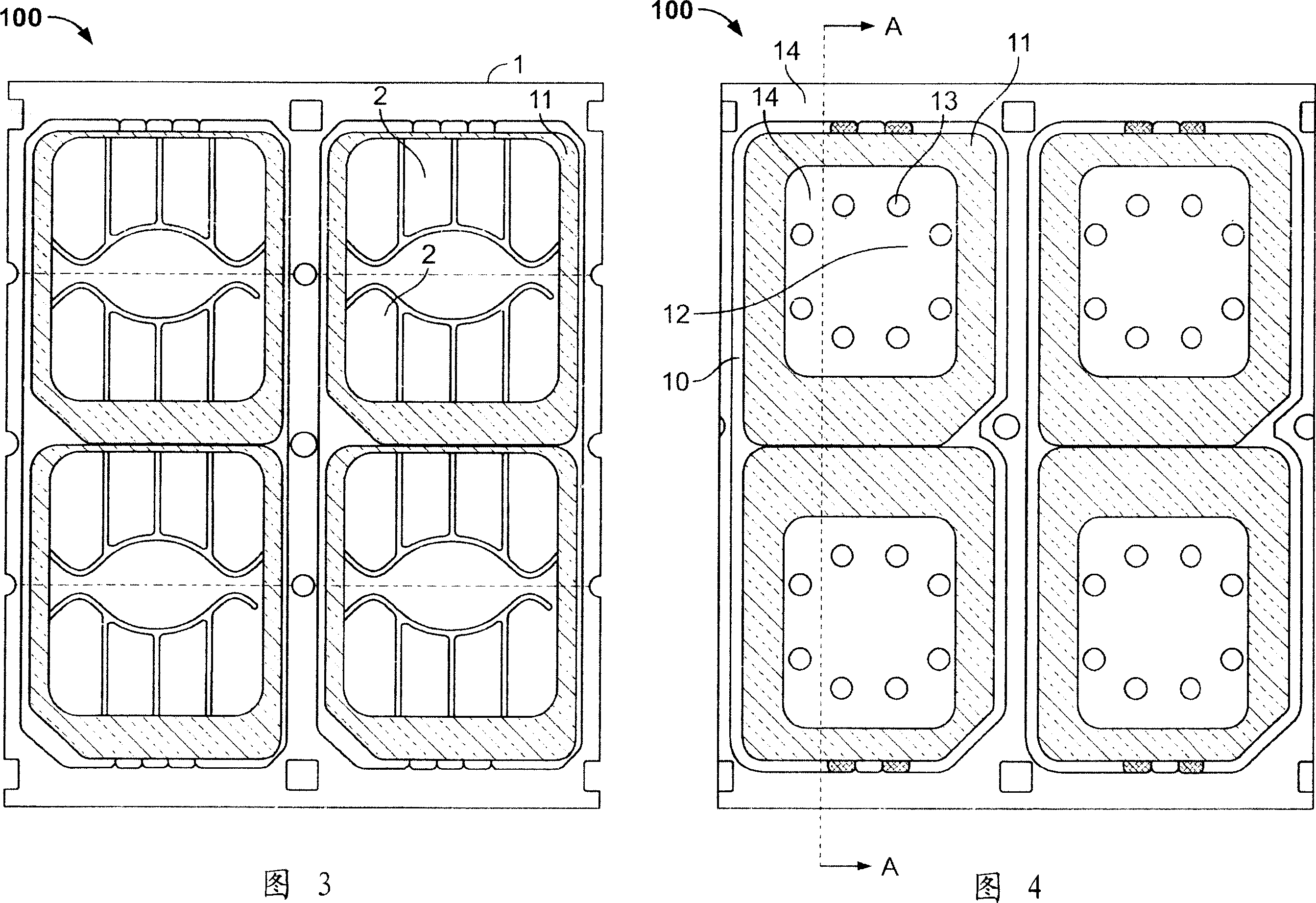

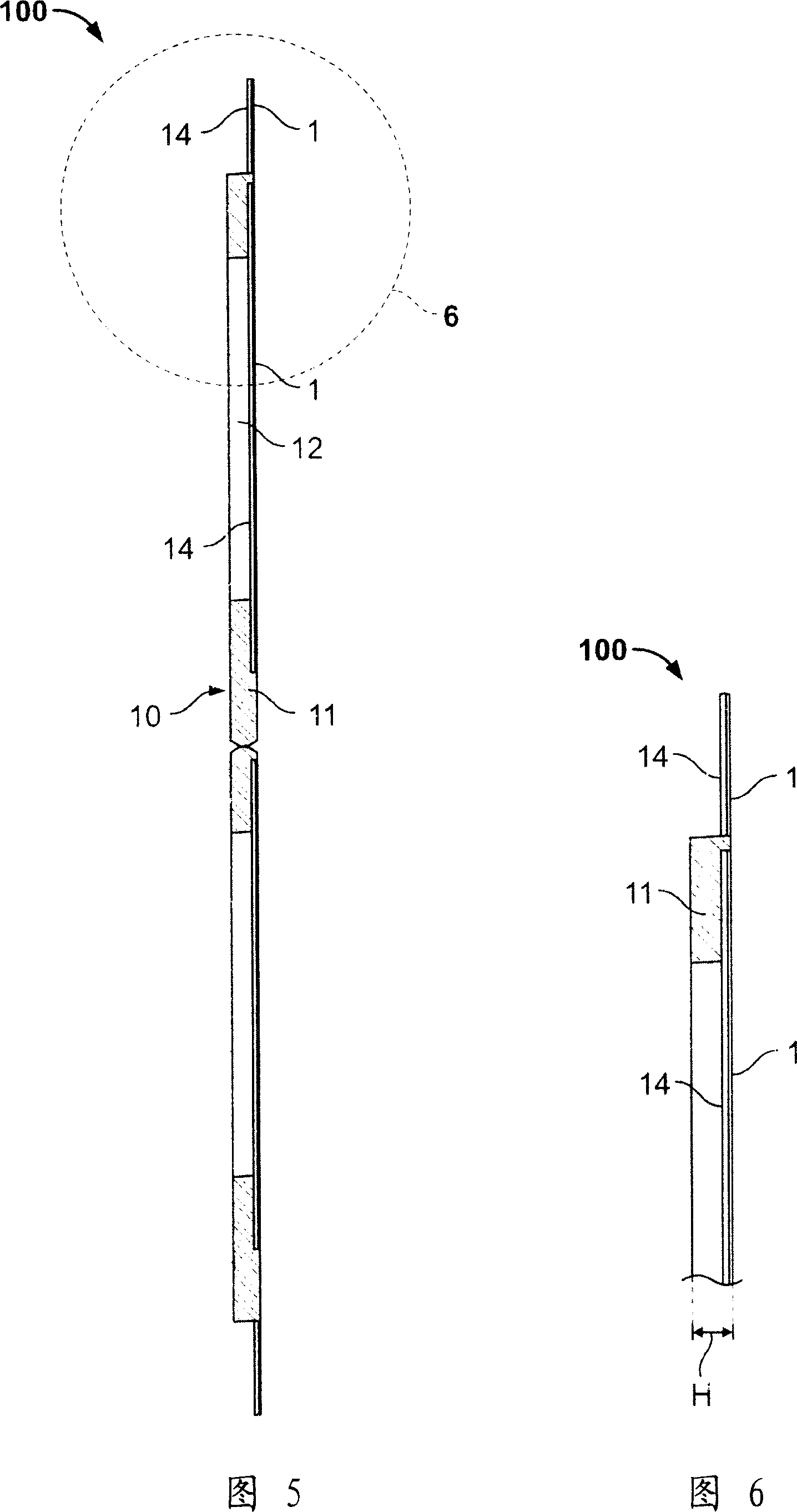

[0031] Figures 1, 2 and 3 show top views of the first surface of the carrier tape. Figure 4 shows a top view of a second surface opposite the first surface. Therefore, Fig. 1, Fig. 2 and Fig. 3 and Fig. 4 show top views of two sides of a smart card body according to the present invention.

[0032] As can be seen from FIG. 1 , a large number of smart card bodies 10 are manufactured on a carrier tape 100 . The carrier strip 100 is formed from an electrically conductive layer 1 , which preferably consists of a copper sheet. However, other conductive materials such as aluminum may also be used. The carrier tape 100 preferably consists of a roll of the conductive layer 1, so that a large number of smart card bodies 10 can be produced using the roll-to-roll method.

[0033] A method of manufacturing a smart card body 10 including a semiconductor chip will be explained with the aid of FIGS. 1 , 2 and 3 .

[0034] Firstly, holes are drilled in the conductive layer 1 and a lead fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com