Universal precision displacement measurement auxiliary device and measuring method

A technology of precision displacement and auxiliary device, applied in the fields of precision measurement, machining, and precision machining, can solve the problems of high requirements for use conditions, high price, difficult to use, etc., and achieves low manufacturing cost, high sensitivity, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment is described in detail as follows:

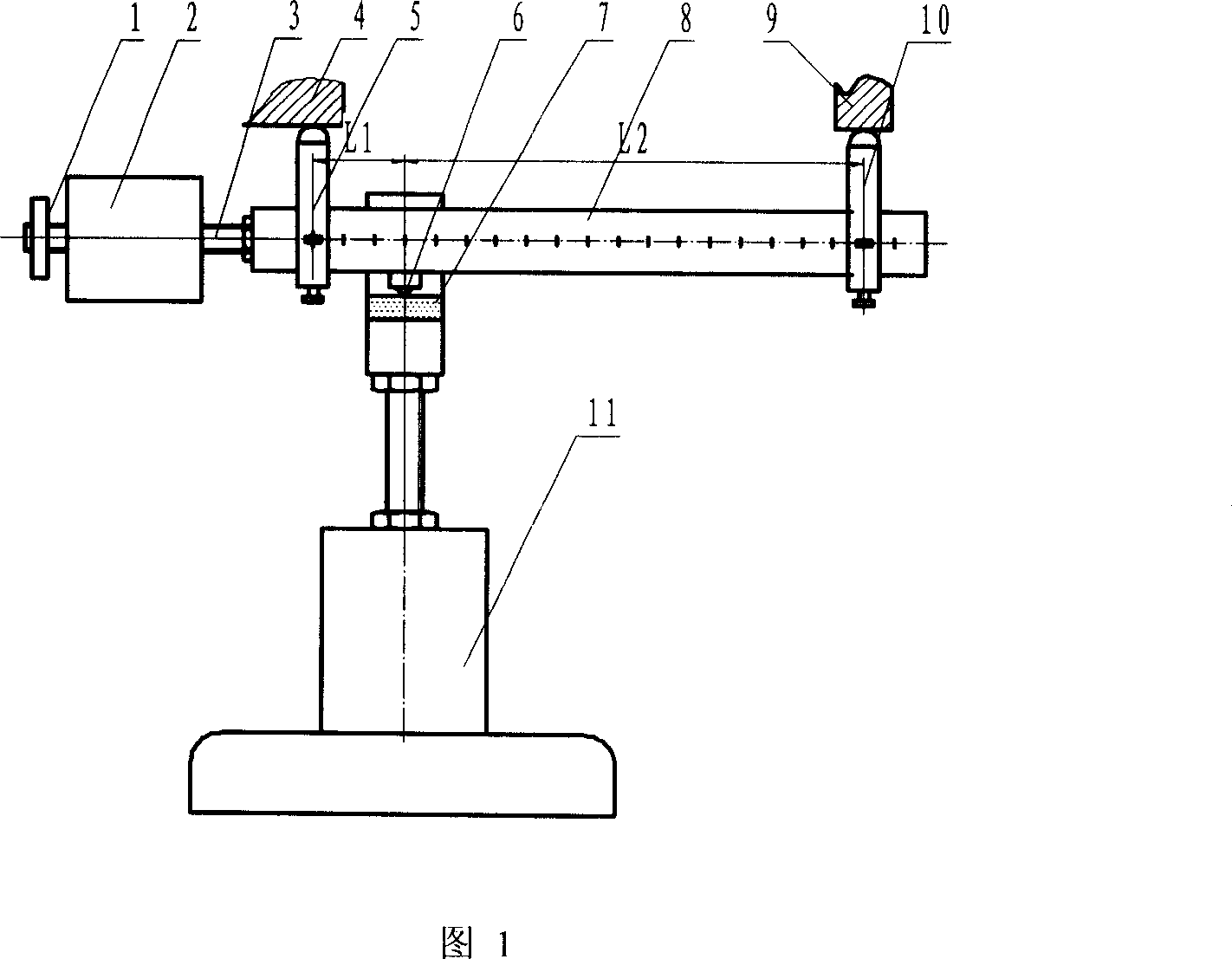

[0032] As shown in Figure 1, the relevant functional parameters of this embodiment are specifically as follows:

[0033] The size of the lever shaft Φ = 10mm

[0034] Length of lever active arm L1=20mm

[0035] The length of lever active arm L2=200mm

[0036] The material of supporting knife and supporting block adopts hard alloy and hard knife-edge type supporting.

[0037] Its working process is shown in Figure 1; the process of micro-displacement measurement is:

[0038] (1) Adjust the positions of the first measuring head 5 and the second measuring head 10 according to the accuracy of the displacement measuring instrument used and the requirements of measuring accuracy, so as to obtain the required magnification. Assume that the magnification adjustment K=20 times.

[0039] (2) Adjust the position of the coarse balance weight so that the lever is in a balanced state, so as to minimize the influence of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com