Electromagnetic coefficient tester for electromagnetic material and testing method thereof

A technology of magnetoelectric materials and testers, which is applied in the direction of magnetic performance measurement, current/voltage measurement, instruments, etc., can solve the problems of not being able to measure the continuous change curve of the magnetoelectric coefficient, taking a lot of time and manpower, and having no magnetoelectric coefficient. Achieve test standardization, reduce labor intensity, and save test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Principle of the present invention, structure and specific implementation will be further described below in conjunction with accompanying drawing:

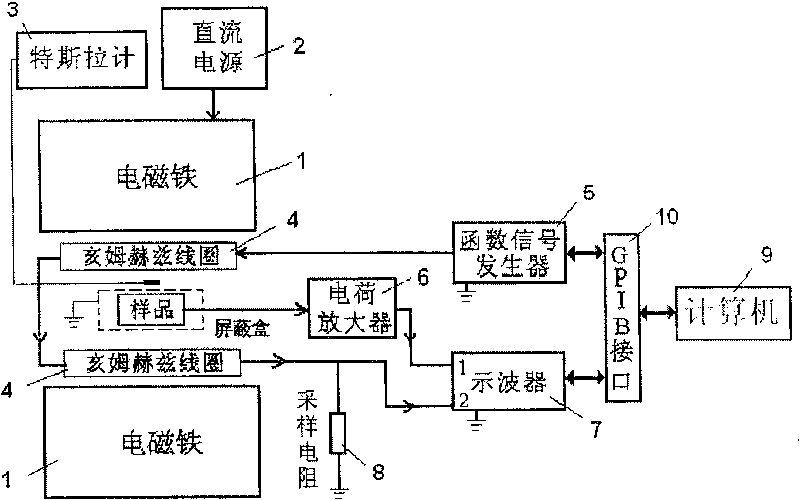

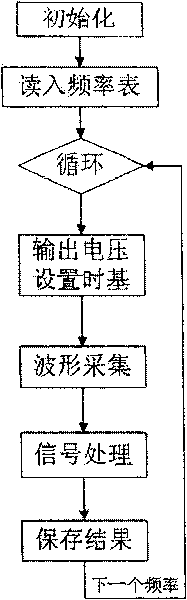

[0029] The circuit connection block diagram of the tester is as follows: figure 1 shown. The composition of the tester can be divided into the following parts:

[0030] (1) DC magnetic field generator

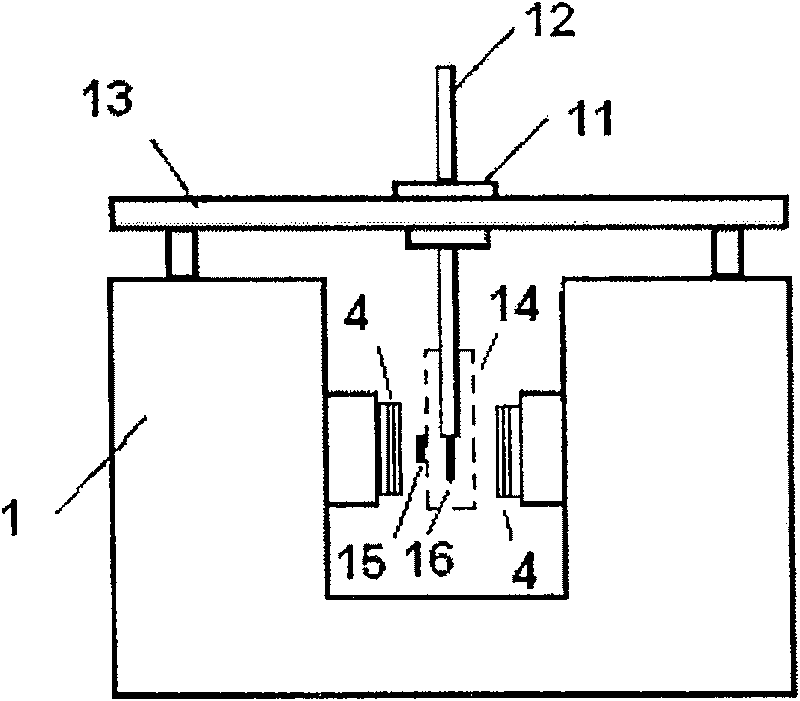

[0031] Including: electromagnet 1, DC power supply 2 and Tesla meter 3. The DC power supply drives the electromagnet to generate a DC bias magnetic field H DC . The probe 15 of the Teslameter is placed between the magnetic poles of the electromagnet for measuring H DC size and direction, such as figure 2 shown. Changing the output current of the DC power supply can change the H DC the size of.

[0032] (2) AC magnetic field generator

[0033] Including: Helmertz coil 4 and function signal generator 5. The function signal generator outputs a sinusoidal voltage with a frequency from 100Hz to 200kHz, driving the He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com