Dryer for drying precipitated calcium carbonate

A dryer, drying technology, applied in the direction of calcium carbonate/strontium/barium, non-progressive dryer, drying, etc., can solve the problem of power consumption and reduce the overall size of the dryer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

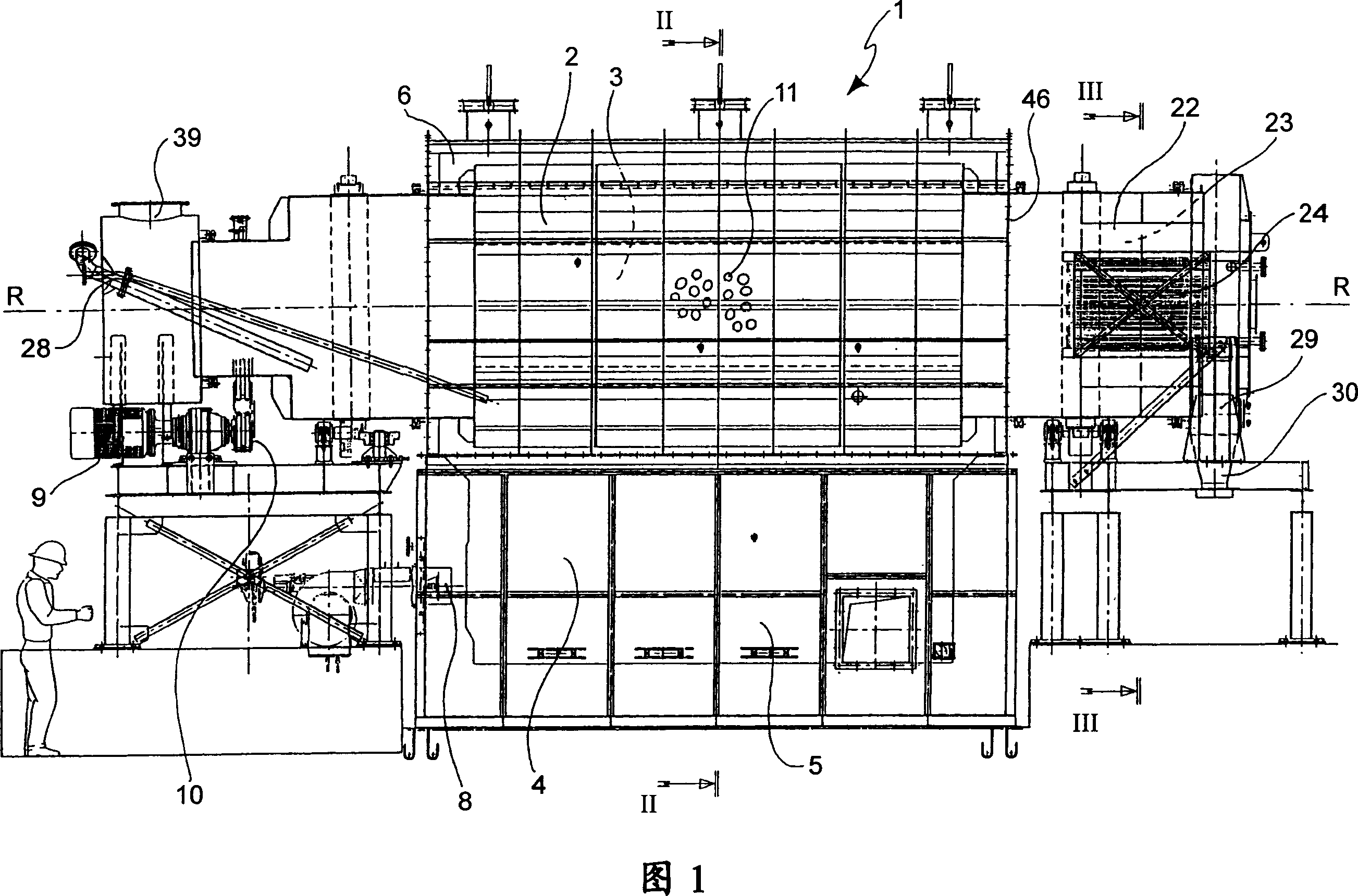

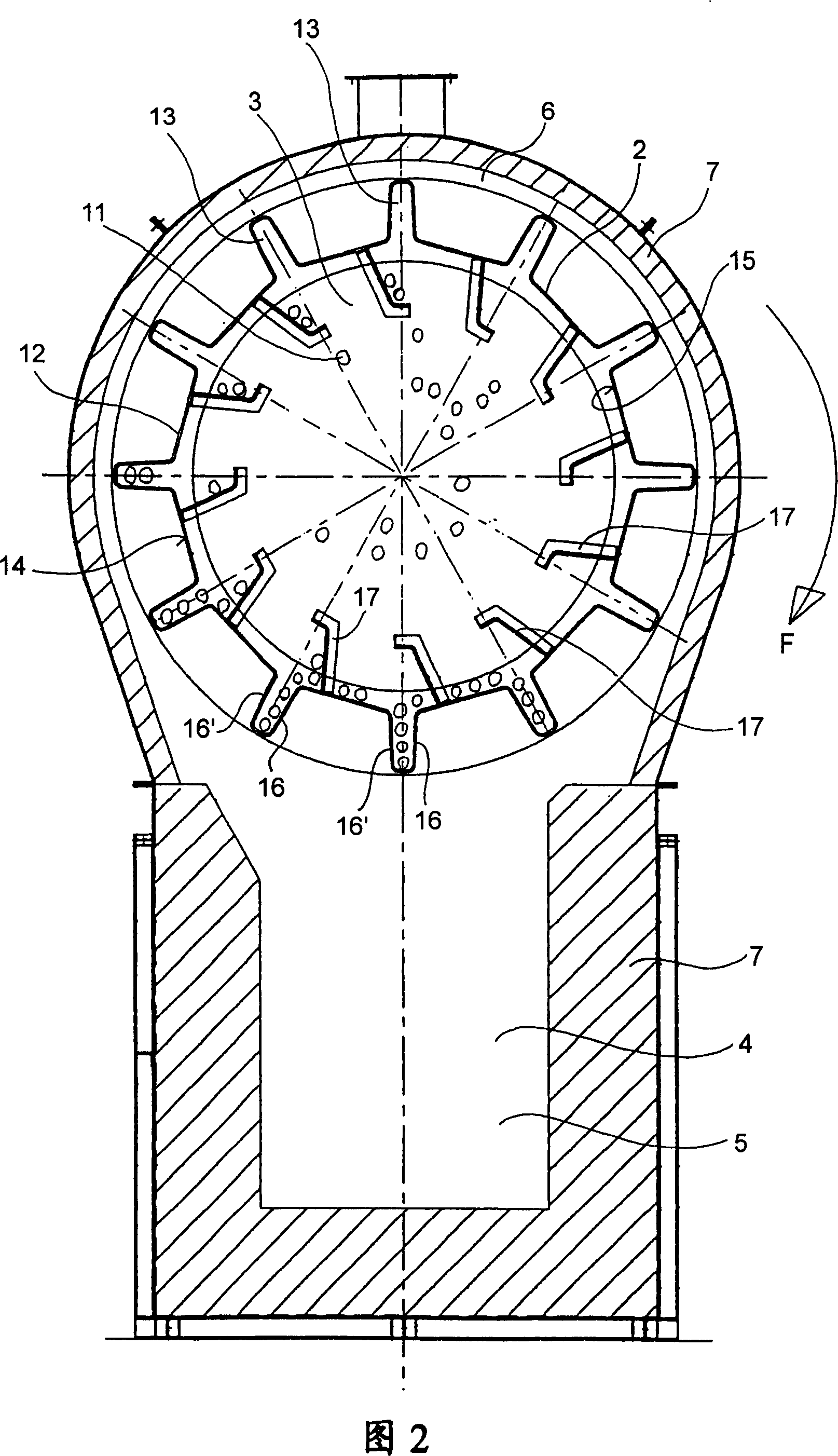

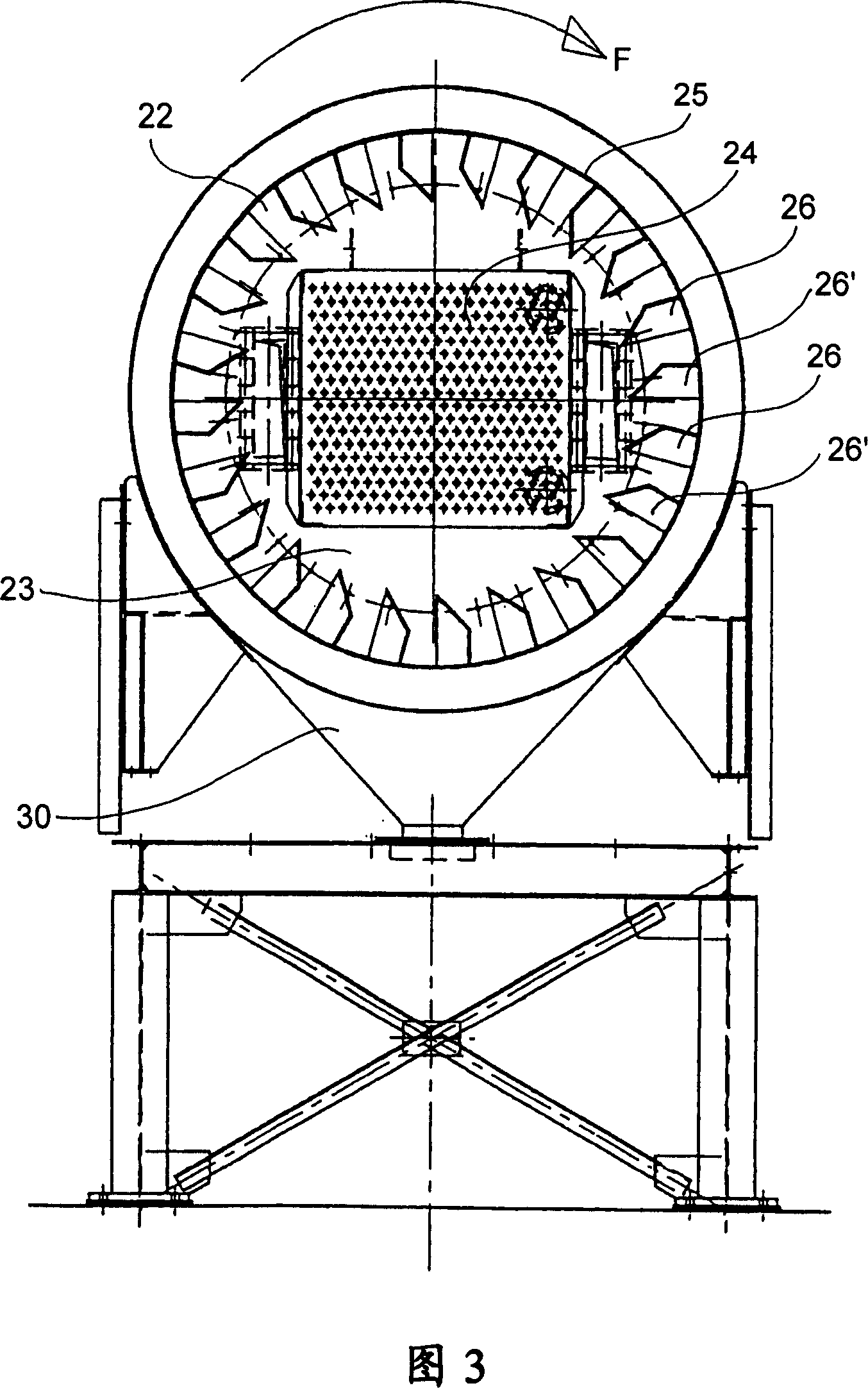

[0027] With reference to accompanying drawing, the dryer that is used for the drying of precipitated calcium carbonate slurry is represented with reference number 1. Considering that during the drying process the precipitated calcium carbonate slurry (a slush of small particles suspended in water) always becomes thicker and thicker until it becomes very little residual moisture (approximately 0.5% by weight %) of very fine precipitated calcium carbonate powder, so the term PCC (precipitated calcium carbonate) will be used in the following description and claims to denote liquid or moist calcium carbonate slurry and dried calcium carbonate powder during processing .

[0028] The dryer 1 comprises a drying chamber 2, preferably a metal cylindrical drum, such as carbon steel or stainless steel, which defines an internal drying space 3 for containing PCC to be dried.

[0029] The drying chamber 2 is located in the combustion chamber 4 . The combustion chamber 4 is parallelepiped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com