Method of producing titania solution

A titanium dioxide solution technology, applied in the field of preparation of titanium dioxide solution, can solve problems such as difficulty in increasing productivity, low heat resistance, inability to perform sufficient roasting, etc., and achieve the effect of easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

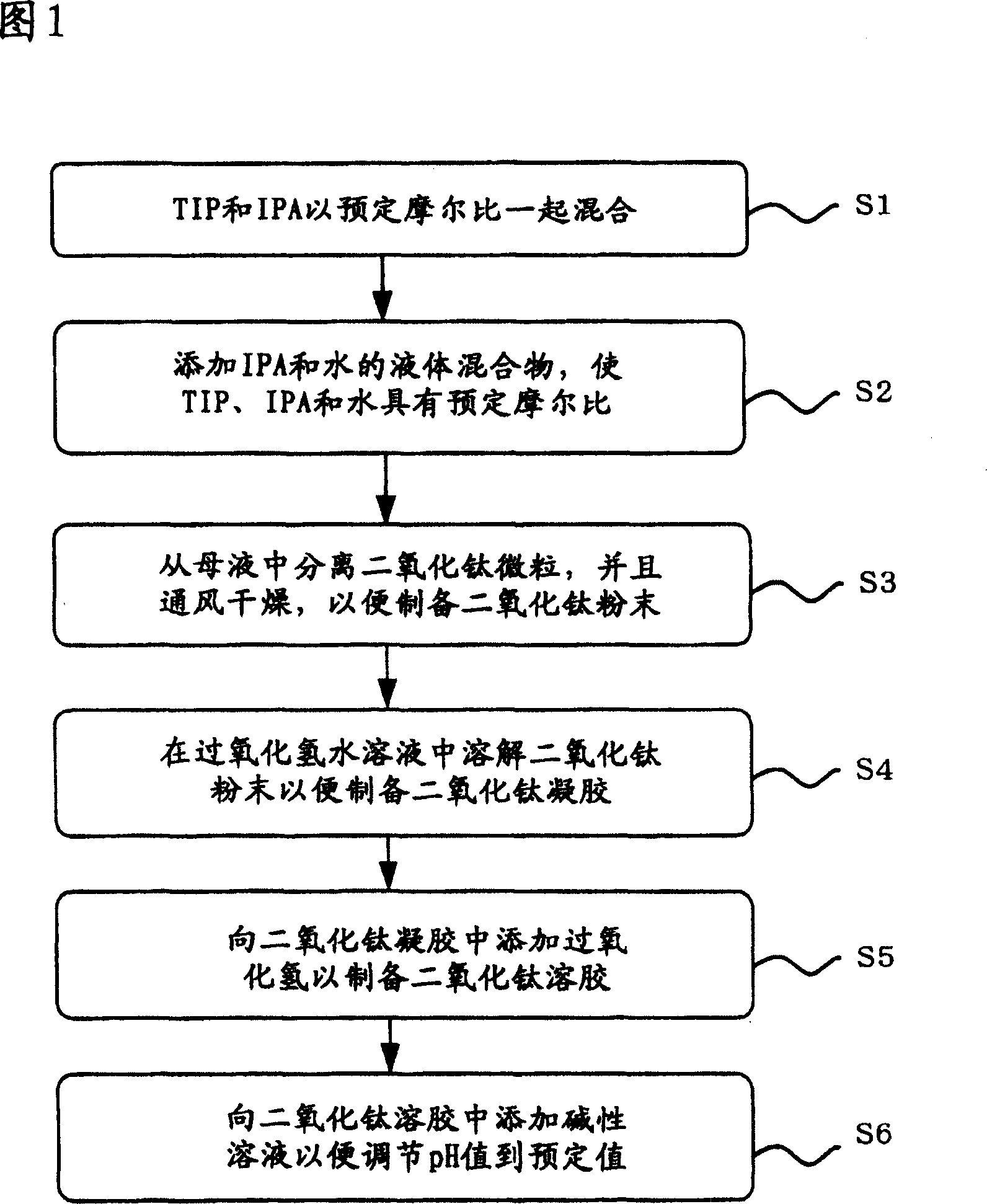

Embodiment 1

[0065]In this example, an amorphous-containing solution was prepared using the method described above. At the beginning, TIP and IPA are mixed together in molar ratio TIP / IPA=1 / 5, then a liquid mixture of IPA and water is added to obtain a liquid mixture with molar ratio TIP / IPA / water=1 / 10 / 4. Subsequently, the liquid mixture was stirred while controlling its temperature at 25°C, so as to prepare titanium dioxide fine particles. Two, separate the titanium dioxide from the mother liquor by suction filtration, and then ventilate and dry at 100° C. to obtain titanium dioxide powder. The titanium dioxide powder was added together with a 31% by weight aqueous hydrogen peroxide solution, and then the solution was stirred while controlling 10° C. so as to obtain a titanium dioxide gel. After further adding a 31% by weight aqueous hydrogen peroxide solution, ammonia water was added to the solution so as to adjust the pH to 7. The thus-obtained solution containing amorphous titanium d...

Embodiment 2

[0073] In this example, titanium dioxide powder was dissolved in an aqueous hydrogen peroxide solution while controlling the solution at a predetermined temperature. This process is equivalent to step S4 in FIG. 1 . First, 1 gram of amorphous titanium dioxide powder was weighed per 100 ml sample bottle, and furthermore, a 15% by weight aqueous hydrogen peroxide solution was added. In this case, the temperatures of the solutions were controlled at 5°C, 10°C, 20°C, 30°C, and 40°C using a thermostat, respectively. Then, for each solution, the time (dissolution time) was calculated from the addition of the aqueous hydrogen peroxide solution until the titanium dioxide was dissolved. When the titanium dioxide powder was not visually observed, it was considered that the titanium dioxide was dissolved.

[0074] (result and discussion of embodiment 2)

[0075] The results of dissolution time at each temperature are shown in FIG. 5 . From this result, it is clear that it was 82 minu...

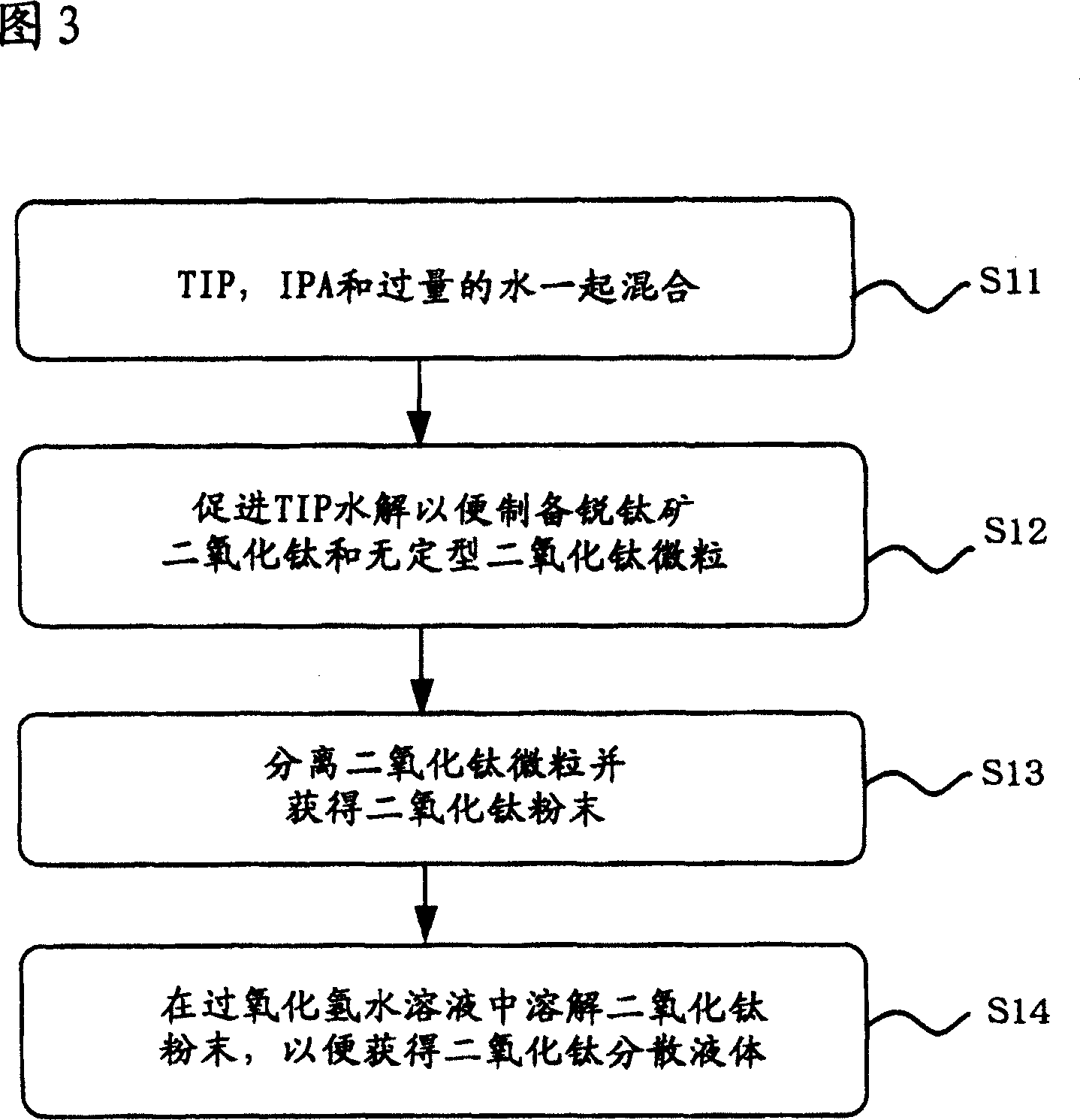

Embodiment 3

[0077] In this example, the titanium dioxide dispersion liquid was prepared using the above method of mixing water in excess relative to TIP. First, TIP, IPA, and water were mixed together at a molar ratio of TIP / IPA / water=1 / 5 / 10 to obtain a liquid mixture. Then, the liquid mixture was stirred while controlling its temperature at 25°C, so as to prepare titanium dioxide fine particles. Titanium dioxide was separated from the mother liquor by suction filtration, and then ventilated and dried at 100° C. to obtain titanium dioxide powder. The titanium dioxide powder was added together with a 31% by weight aqueous hydrogen peroxide solution, and then, while controlling 20° C., the solution was stirred so as to obtain a titanium dioxide dispersion liquid. This dispersion liquid is referred to as solution A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com