Method for improving gelatinization phenomenon of frozen egg yolk during freezing storage period

A technology of gelling and egg yolk, which is applied in the fields of preservation of eggs by freezing/cooling, preservation of eggs, preservation of food ingredients as anti-microbials, etc. phenomenon, improved emulsifying activity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

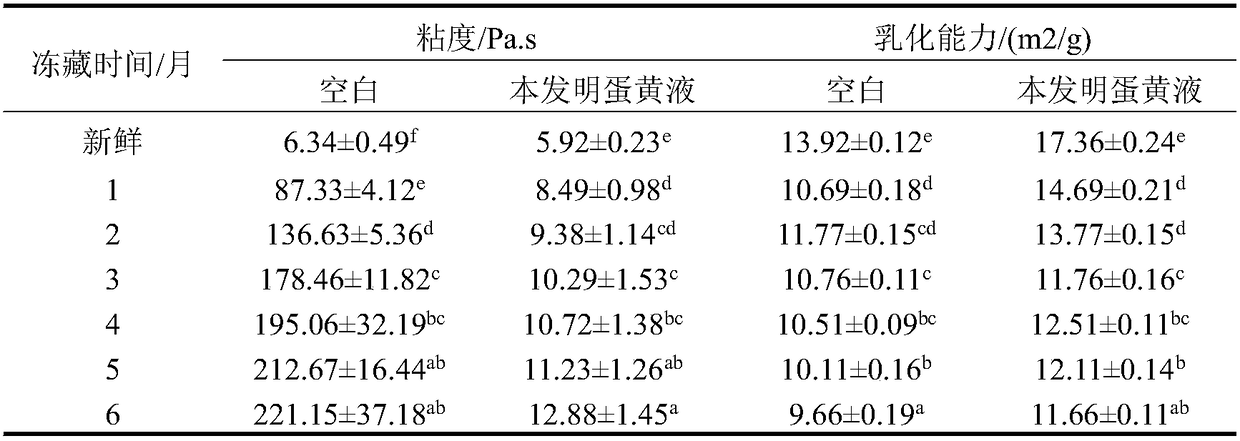

Examples

Embodiment 1

[0031] A method for improving the gelatinization of egg yolks during frozen storage. Select undamaged fresh eggs, wash and dry them, remove the shells, separate the eggs, and stir to obtain fresh egg yolks. Add a certain amount of neutral protease and then enzymatically hydrolyze. Then add a certain proportion of sugar, then homogenize, then quick freeze for 24 hours, and finally store at -18°C. Take the following steps.

[0032] (1) Select fresh eggs, wash, beat and separate the eggs, and stir for 20 minutes at a rotating speed of 400r / min to obtain fresh egg yolk liquid for subsequent use.

[0033] (2) Add 0.04% alkaline protease to the egg yolk liquid obtained in the above step (1), and enzymolyze it at 35° C. for 35 minutes.

[0034] (3) Add 2% sugar to the egg yolk liquid obtained in the above step (2), the ratio of galactose: sucrose: maltooligosaccharide glucose is 1:5:4

[0035] (4) Homogenize the egg yolk liquid obtained in the above step (3) for 2 minutes.

[0036...

Embodiment 2

[0039] (1) Select fresh eggs, wash, beat and separate the eggs, and stir for 15 minutes at a rotating speed of 600r / min to obtain fresh egg yolk liquid, which is set aside.

[0040] (2) Add 0.06% papain and neutral protease to the egg yolk liquid obtained in the above step (1), and enzymolyze it at 40° C. for 30 minutes.

[0041] (3) Add 0.5% sugar to the egg yolk liquid obtained in the above step (2), and the ratio of maltose: sucrose: trehalose is 2:4:4

[0042] (4) Homogenize the egg yolk liquid obtained in the above step (3) for 1 min.

[0043] (5) Pasteurize the egg yolk liquid obtained in the above step (4) at 63.5° C. for 120 s.

[0044] (6) Quick-frozen packaging, the egg yolk liquid was quick-frozen at -28°C for 24 hours. Then refrigerated in -18°C freezer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com