Method for producing anionic extinction deposition coating composition having high flash point

An anionic, manufacturing method technology, applied in electrophoretic coatings, coatings, etc., can solve the problems of dangerous goods, increase transportation costs and storage costs, and achieve the effect of increasing flash point and reducing transportation and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

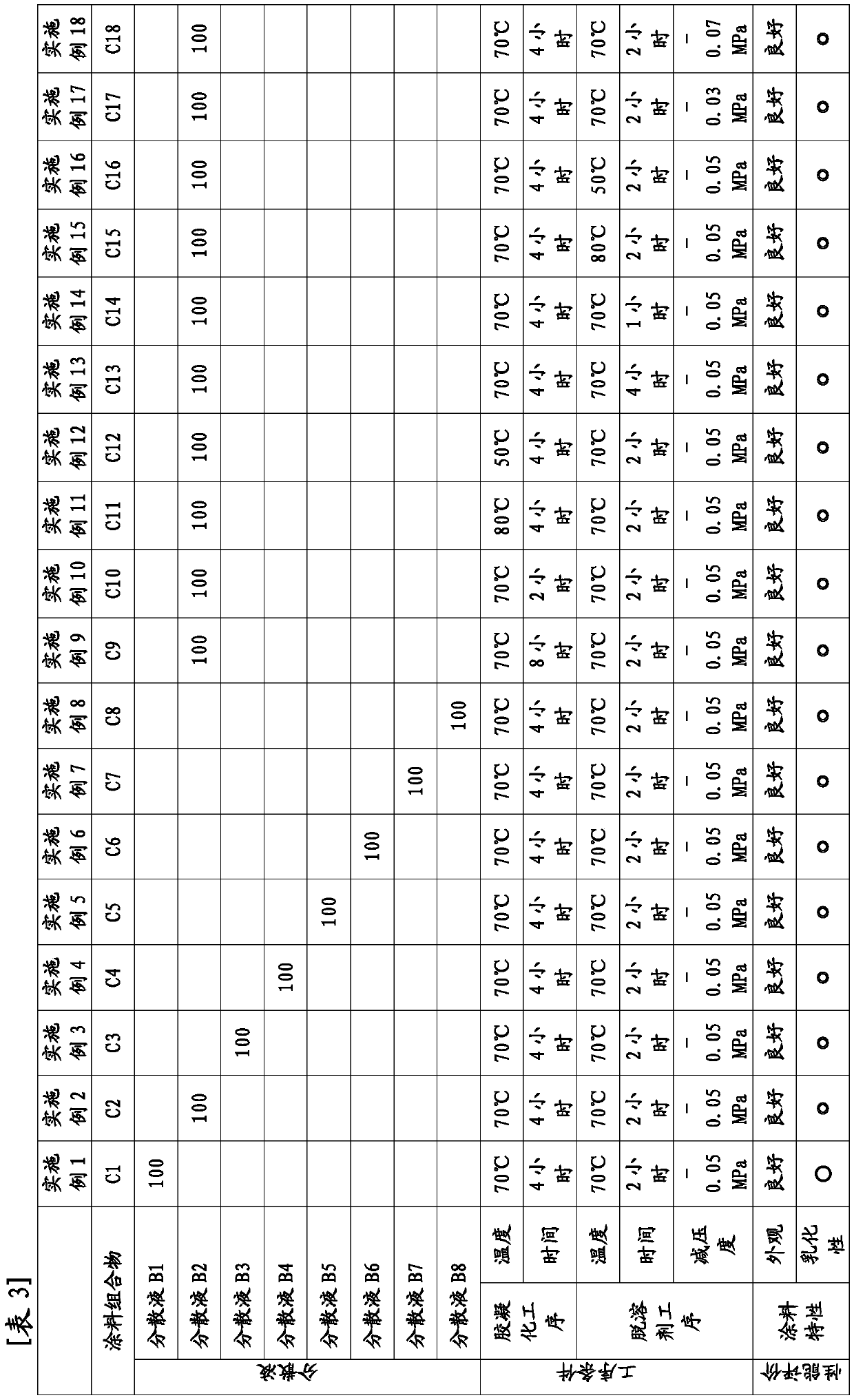

Examples

Embodiment

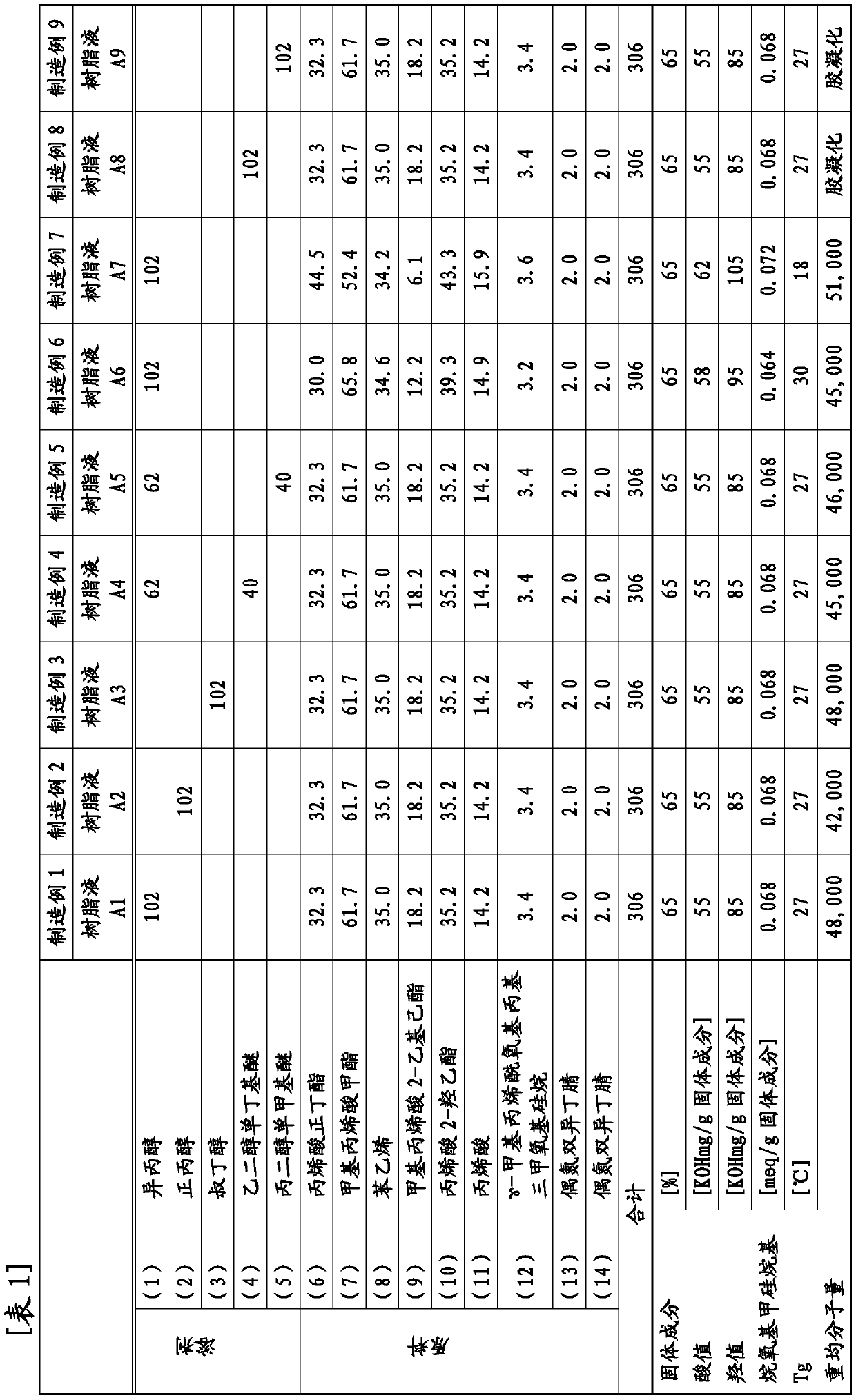

[0062] Hereinafter, the present invention will be explained in more detail with examples, but the present invention is not limited to these. In addition, unless otherwise specified, the compounding amount (parts, %) in the table means parts by mass and% by mass.

[0063] ((A) Production of vinyl copolymer)

manufacture example 1

[0064] Manufacturing example 1 (manufacturing of resin liquid A1)

[0065] Prepare a reaction device with a stirring device, a thermometer, a monomer dropping device, and a reflux condenser.

[0066] The (1) in Table 1 was put into a reaction device, the reflux temperature was raised with stirring, and (6) to (13) were uniformly mixed in advance, and then added dropwise over 3 hours. The temperature is maintained at the reflux temperature.

[0067] After 1.5 hours had passed from the end of the dropping, (14) was added, and the reaction was continued at the same temperature for 1.5 hours to obtain a resin liquid A1 for a transparent and viscous matte coating with a solid content of 65%.

[0068] The acid value (KOHmg / g solid content), hydroxyl value (KOHmg / g solid content), equivalent of alkoxysilyl group (meq / g solid content), Tg (°C), and weight average molecular weight of the resin liquid are also shown in Table 1.

manufacture example 2~9

[0069] Manufacturing examples 2-9 (manufacturing of resin liquid A2-A9)

[0070] Except having adopted the compounding amounts described in Table 1, the same method as in Production Example 1 was used to produce resin liquids A2 to A9.

[0071] In addition, for resin liquid A8 (for Comparative Example 2) using only ethylene glycol monobutyl ether as a solvent, and resin liquid A9 (for Comparative Example 3) using only propylene glycol monomethyl ether as a solvent, During the resin reaction, the resin gelled and became a gel, and the resin liquid could not be produced.

[0072]

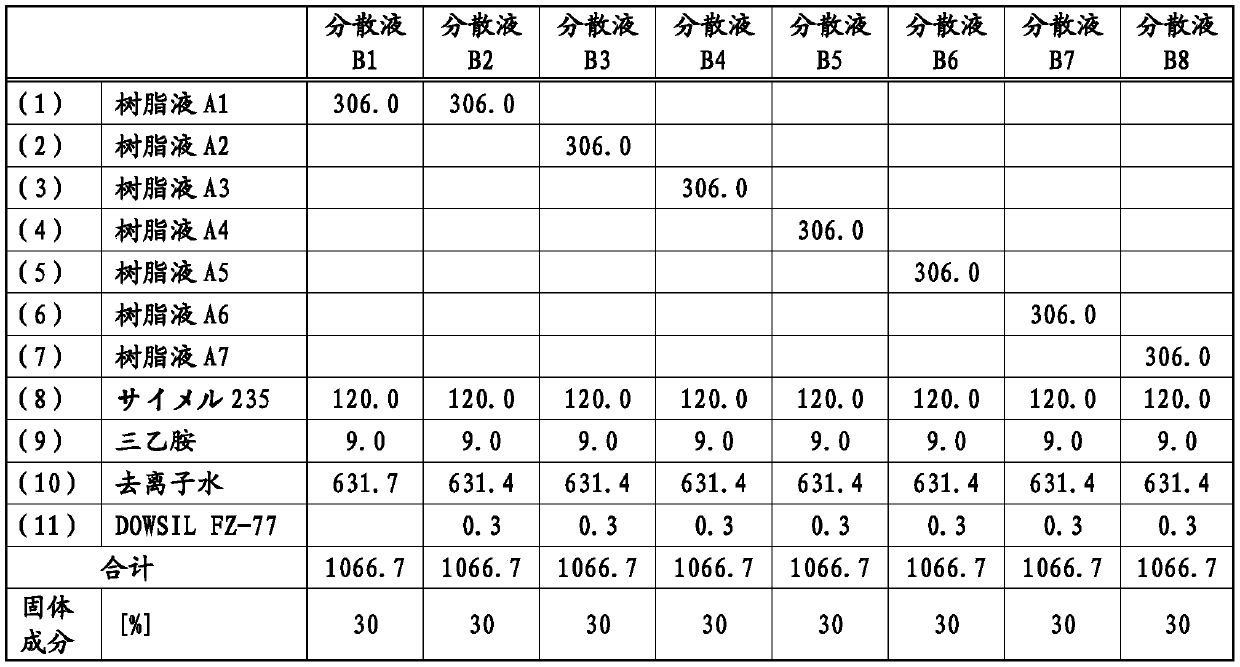

[0073] (Manufacture of dispersion B1)

[0074] Prepare a reaction device with a stirring device, a thermometer, a deionized water dripping device, and a reflux condenser.

[0075] According to the compounding quantity shown in Table 2, (1) and (8) were put into a reaction apparatus, and it stirred and mixed at 60 degreeC for 1 hour. The mixed liquid of (9) and (10) was slowly added thereto and dispersed in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com