Pipe network for connecting holed metal skeleton reinforced plastic composite pipe and plastic connector

A technology of plastic connectors and metal skeletons, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, pipes, etc., and can solve problems such as the difficulty of sealing skeletons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

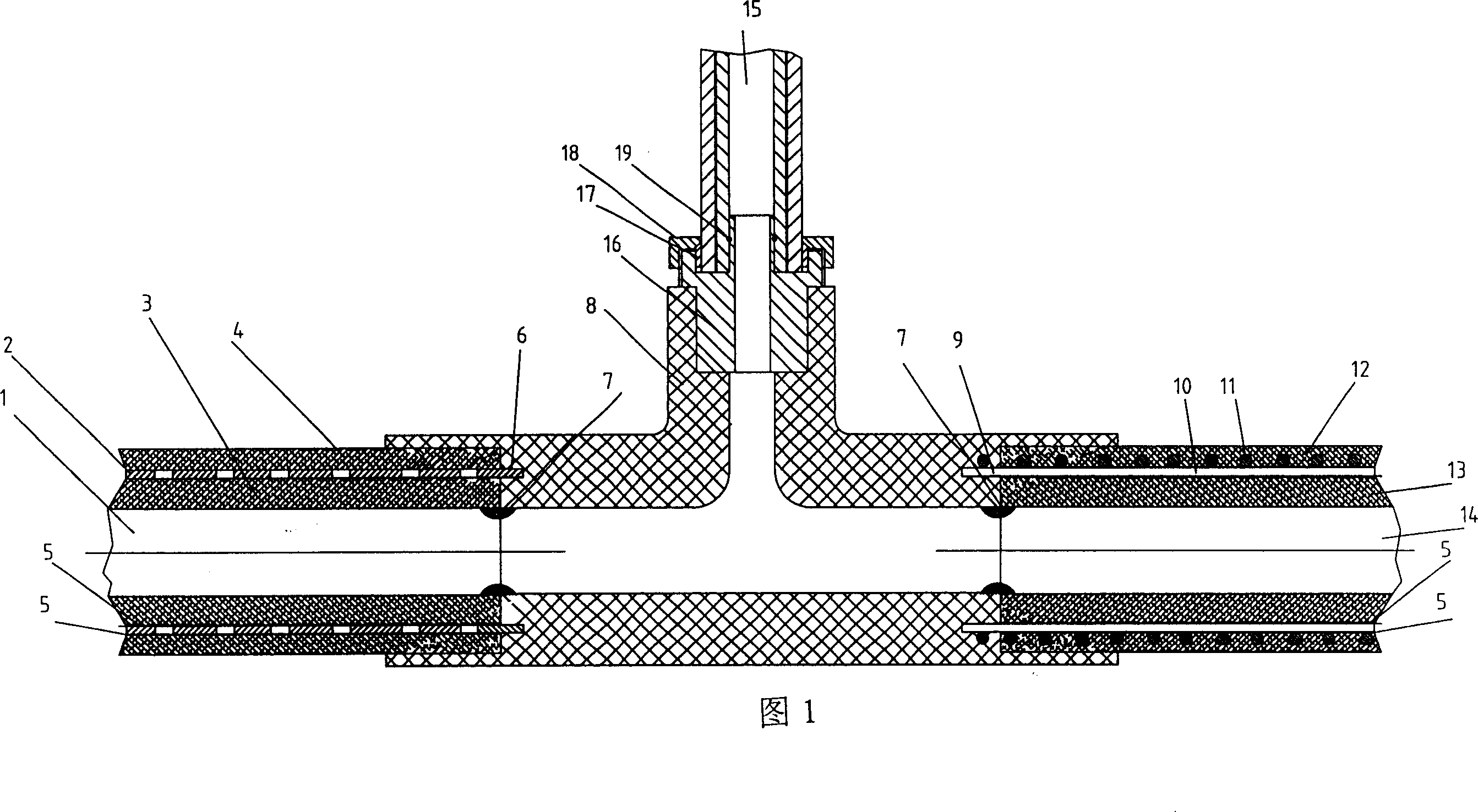

[0029] Fig. 1 has provided the figure of embodiment 1 of the present invention. Referring to Fig. 1, the steel-plastic composite pipe 1, the aluminum-plastic composite pipe 15, the latitudinal steel wire 11 and the radial steel wire 10 are welded into a composite pipe with a porous steel wire skeleton, which are connected by a three-way pipe connector 8 14 formed pipe network. The material of the plastic outer layer 4 in the steel-plastic pipe compounded with perforated steel strips is non-crosslinked heat-resistant polyethylene (PE-RT), which is melted and connected with the pipe connector 8, and the metal skeleton formed by butt welding of the perforated steel strips Part of the metal skeleton 6 exposed at one end of 2 extends into the end face 7 of the ring-shaped step in the inner cavity of the socket of the pipe fitting 8 by 4 mm, and is a plastic melt that is melted and connected together by the end face of the wall of the composite pipe 1 and the end face 7 of the ring-...

Embodiment 2

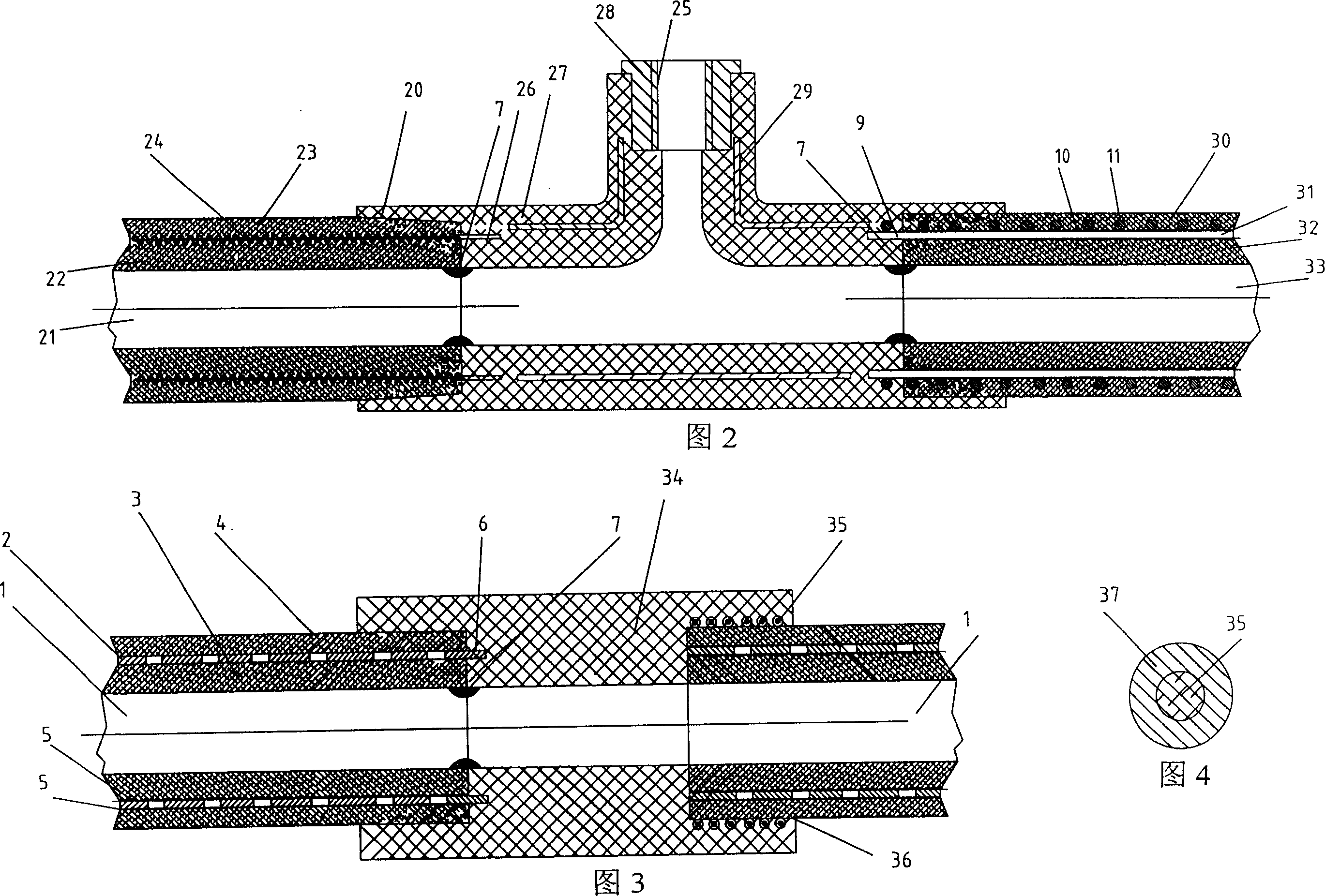

[0033] Fig. 2 has provided the figure of embodiment 2 of the present invention. Embodiment 2 is basically the same as Embodiment 1. The difference is that the inner layer 22 and outer layer 23 of the pipe 21 are all made of heat-resistant polypropylene (PP-R) or high-density polyethylene (HDPE), the pipe fitting 27 is a tee, and there is a steel plate skeleton 29 in the middle of the pipe fitting body. The connection at one end of the small diameter is to use the copper insert 28 with thread 25, and the metal skeleton 31 of the composite pipe 33 at the right end of the pipe fitting is formed by winding the radial steel wire 10 with the latitudinal steel wire 11 and welding. The inner layer 32 and the outer layer 30 of the pipe 33 The materials are all heat-resistant polypropylene (PP-R) or high-density polyethylene (HDPE). The metal skeleton of the composite pipe at the other end is wound with steel wire 24 left and right helically to form a skeleton. The end face 7 of the an...

Embodiment 3

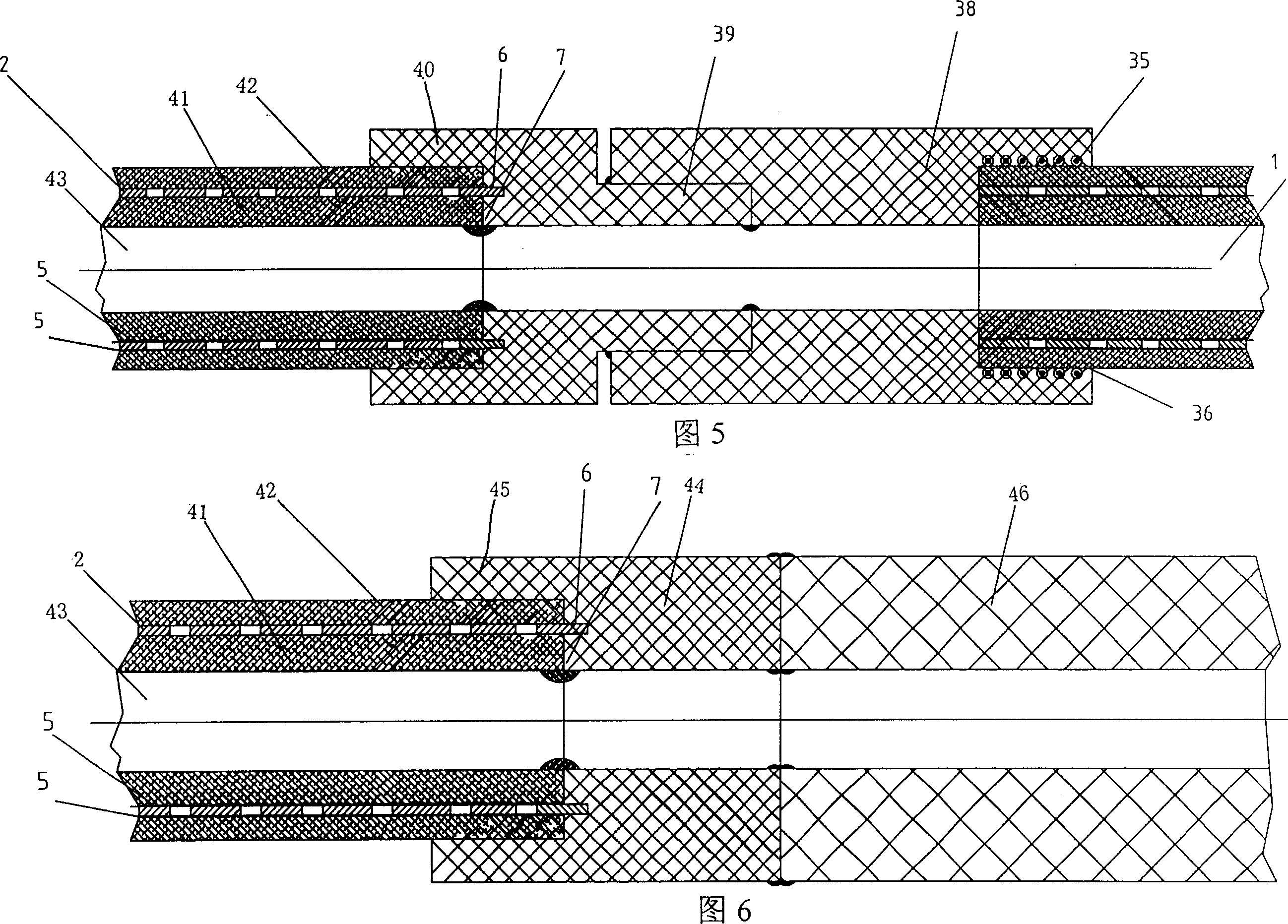

[0035] Fig. 3, Fig. 4 have provided embodiment 3 figure of the present invention. Embodiment 3 is basically the same as Embodiment 1. The difference is that the pipe fitting 34 made of non-cross-linked temperature-resistant polyethylene (PE-RT) is a two-way connection, one end is butt-welded with a perforated steel strip and a non-cross-linked temperature-resistant polyethylene compound with an adhesive layer 5 The end of the pipe 1 is hot-melt and socket connected, and the part of the metal skeleton 6 exposed at one end extends into the end face 7 of the annular step in the inner cavity of the socket of the pipe fitting 34. 7. The plastic melts that are melted and connected together are covered and sealed; the other end passes through the pipe fitting 34 and is directly inserted into the inner cavity 36 to distribute the heating wire 35 coated with the adhesive and the PE-RT blend 37 (see FIG. 4 ) and non-cross-linked heat-resistant polyethylene composite pipe 1 with a butt-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com