SF6 gas density relay corrector and its detecting method

A density relay and gas density technology, applied in the testing of machine/structural components, instruments, circuits, etc., can solve the problems of poor connection, low temperature acquisition accuracy, high labor intensity, etc., to achieve accurate pressure regulation and control, rich interface Beautiful, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

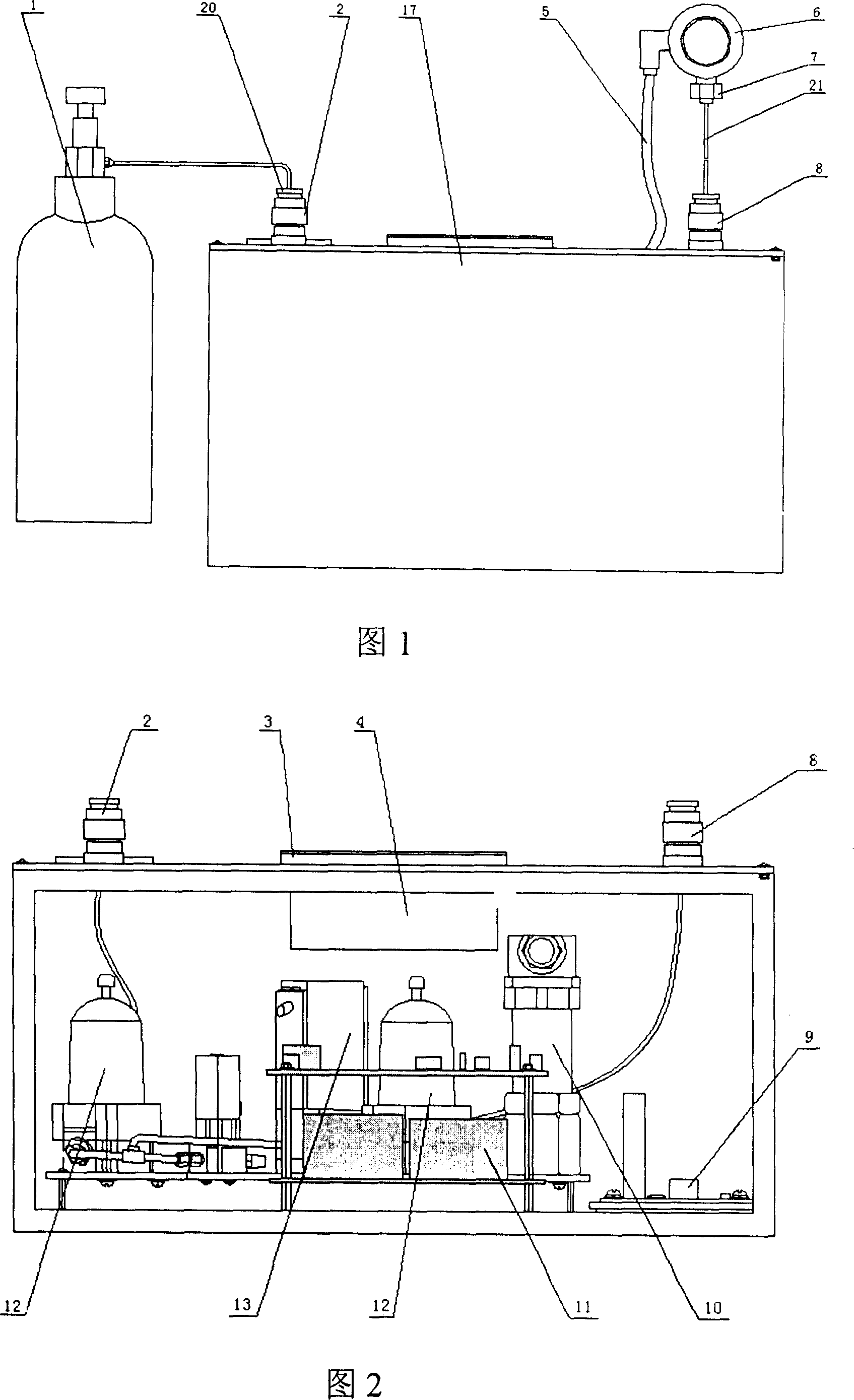

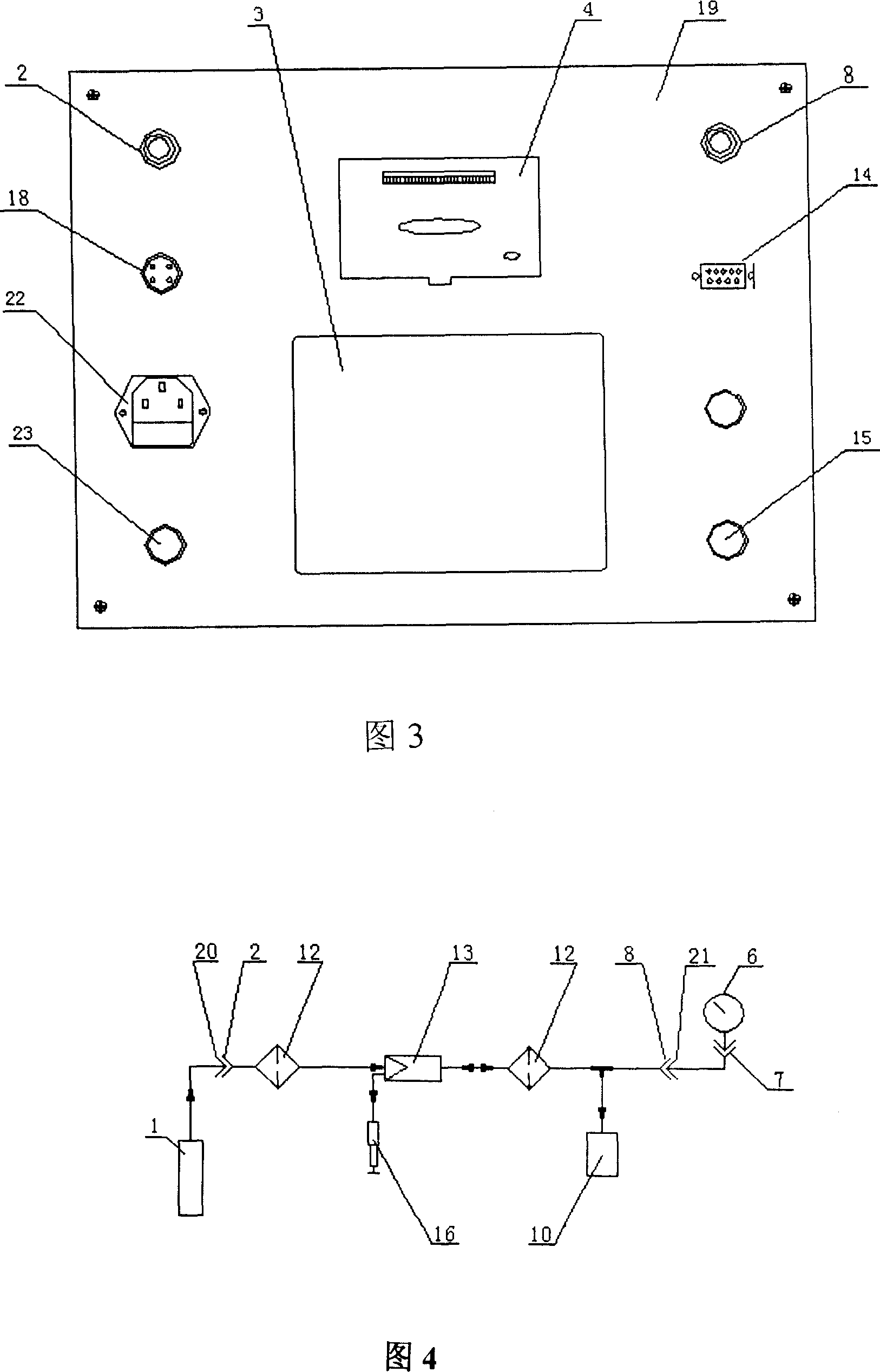

[0047] The first step: connect the SF6 density relay 6 to be tested to the measurement port socket 8 through the transition joint 7 and the test air pipe 21;

[0048] Step 2: SF6 gas cylinder 1 is connected to the air inlet socket 2 through the quick-change plug 20 of the gas circuit;

[0049] Step 3: One end of the test signal line 5 is connected to the SF6 density relay 6 alarm lock contact through the crocodile clip, and the other end is connected to the signal acquisition terminal 18;

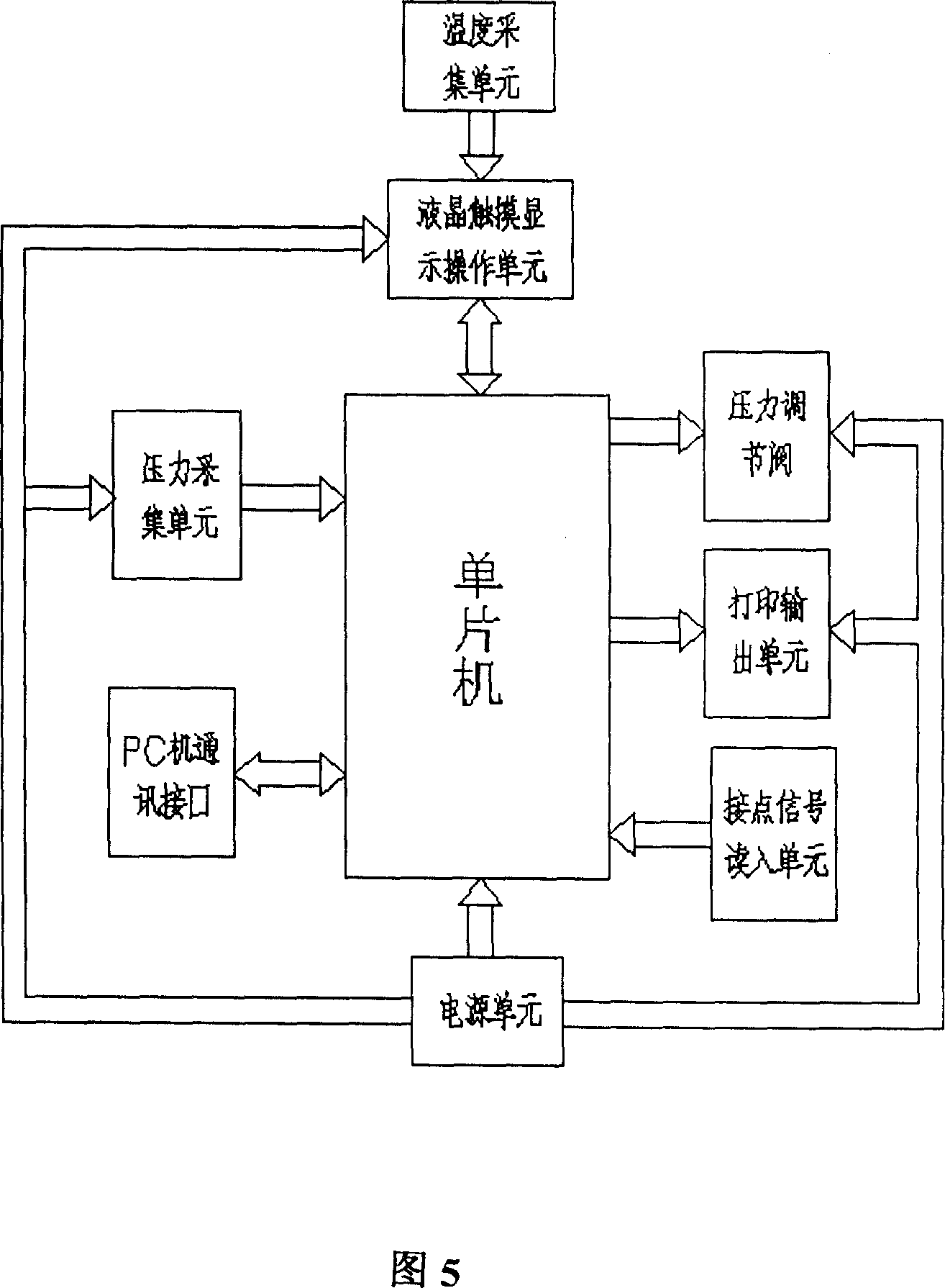

[0050] Step 4: Open the valve on the SF6 gas cylinder 1, press the power switch 23 on the panel 19 to turn on the working power of the device, press the power switch 15 on the panel 19 to turn on the working power of the single-chip microcomputer system 11 and the LCD touch display unit, and the LCD touch display operation The unit displays the initial interface of the system;

[0051] Enter the density relay calibration parameter setting interface through corresponding operations on the i...

Embodiment 2

[0060] The first step: connect the SF6 density relay 6 to be tested to the measurement port socket 8 through the transition joint 7 and the test air pipe 21;

[0061] Step 2: SF6 gas cylinder 1 is connected to the air inlet socket 2 through the quick-change plug 20 of the gas circuit;

[0062] Step 3: One end of the test signal line 5 is connected to the SF6 density relay 6 alarm lock contact through the crocodile clip, and the other end is connected to the signal acquisition terminal 18;

[0063] Step 4: Open the test valve of gas cylinder 1, press the power button 23 on the panel 19 to turn on the working power of the device, press the power button 15 on the panel 19 to turn on the working power of the single-chip microcomputer system 11 and the LCD touch display unit, and the LCD touch display operation The unit displays the initial interface of the system;

[0064] Enter the density relay calibration parameter setting interface through corresponding operations on the init...

Embodiment 3

[0073] The first step: connect the SF6 density relay 6 to be tested to the measurement port socket 8 through the transition joint 7 and the test air pipe 21;

[0074] The second step: the SF6 cylinder 1 is connected to the air inlet socket 2 through the plug 20;

[0075] Step 3: One end of the test signal line 5 is connected to the SF6 density relay 6 alarm lock contact through the crocodile clip, and the other end is connected to the signal acquisition terminal 18;

[0076] Step 4: Open the test valve of gas cylinder 1, press the power switch 23 on the panel 19 to turn on the working power of the device, press the power switch 15 on the panel 19 to turn on the working power of the single-chip microcomputer system 11 and the LCD touch display unit, and the LCD touch display operation The unit displays the initial interface of the system;

[0077] Enter the density relay calibration parameter setting interface through corresponding operations on the initial interface;

[0078...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com