Polymer ptc device

A technology of PTC components and polymers, applied in the direction of electrical components, non-adjustable metal resistors, resistors, etc., can solve the problem of resistance change rate that is impossible to realize the display switch function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

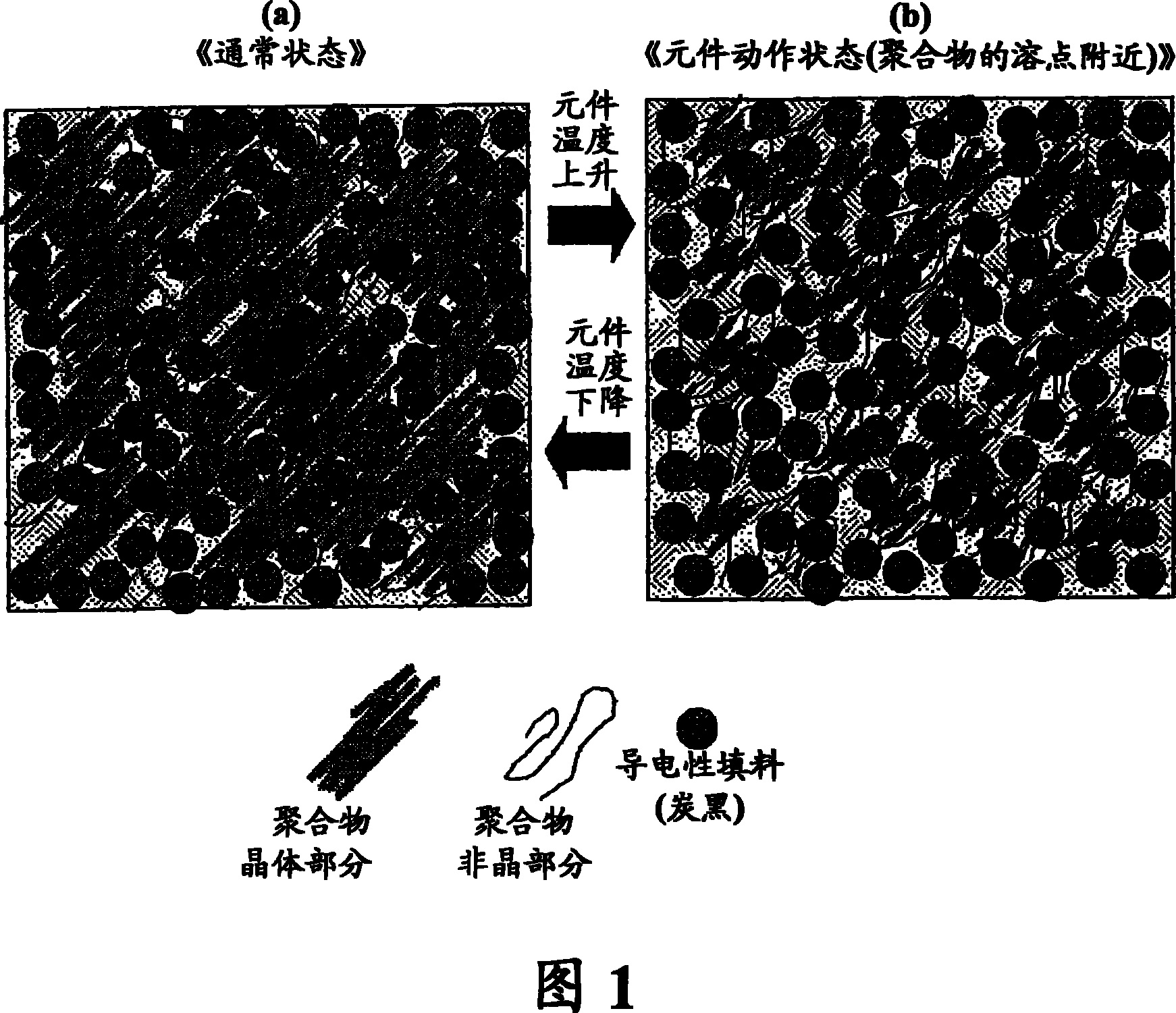

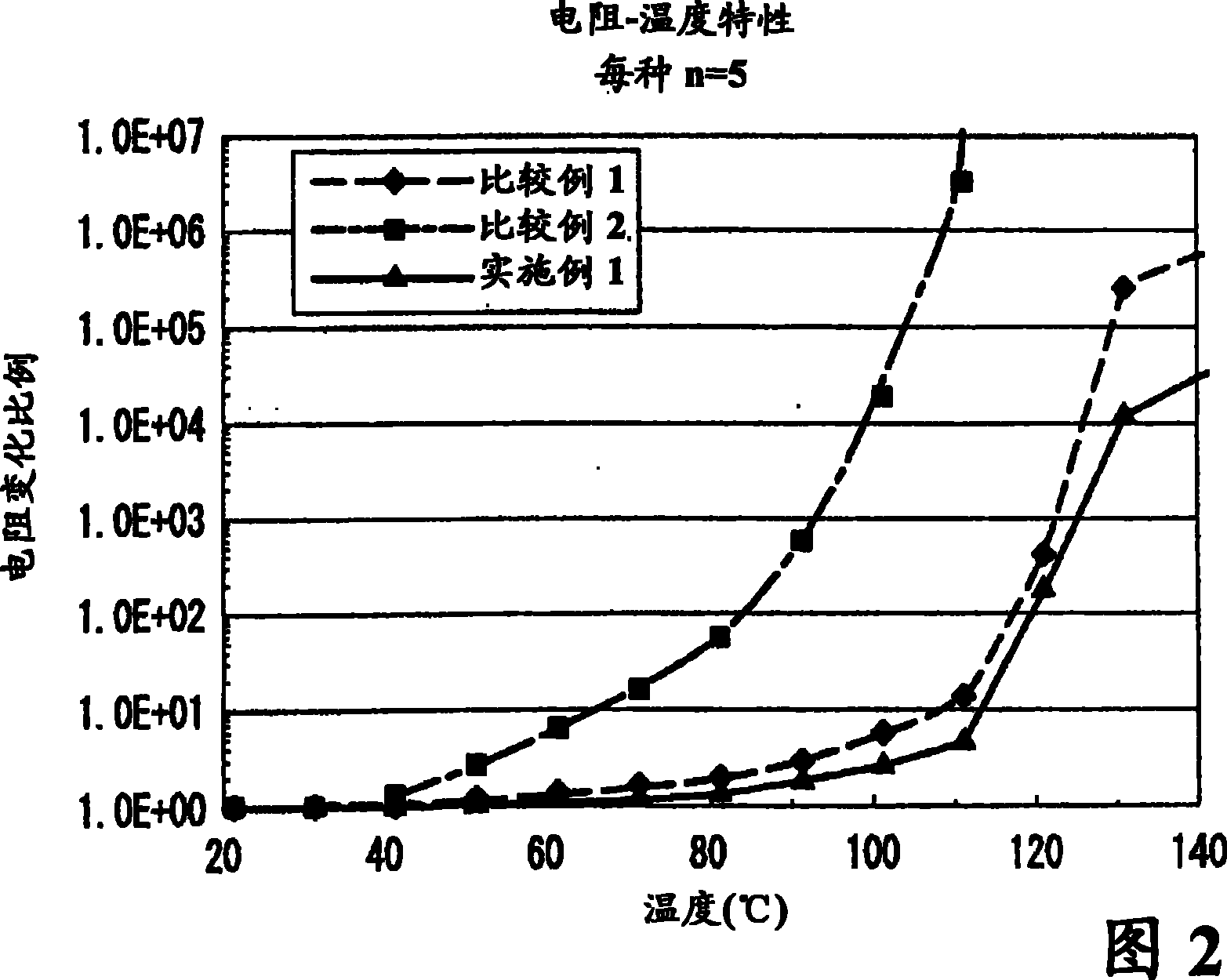

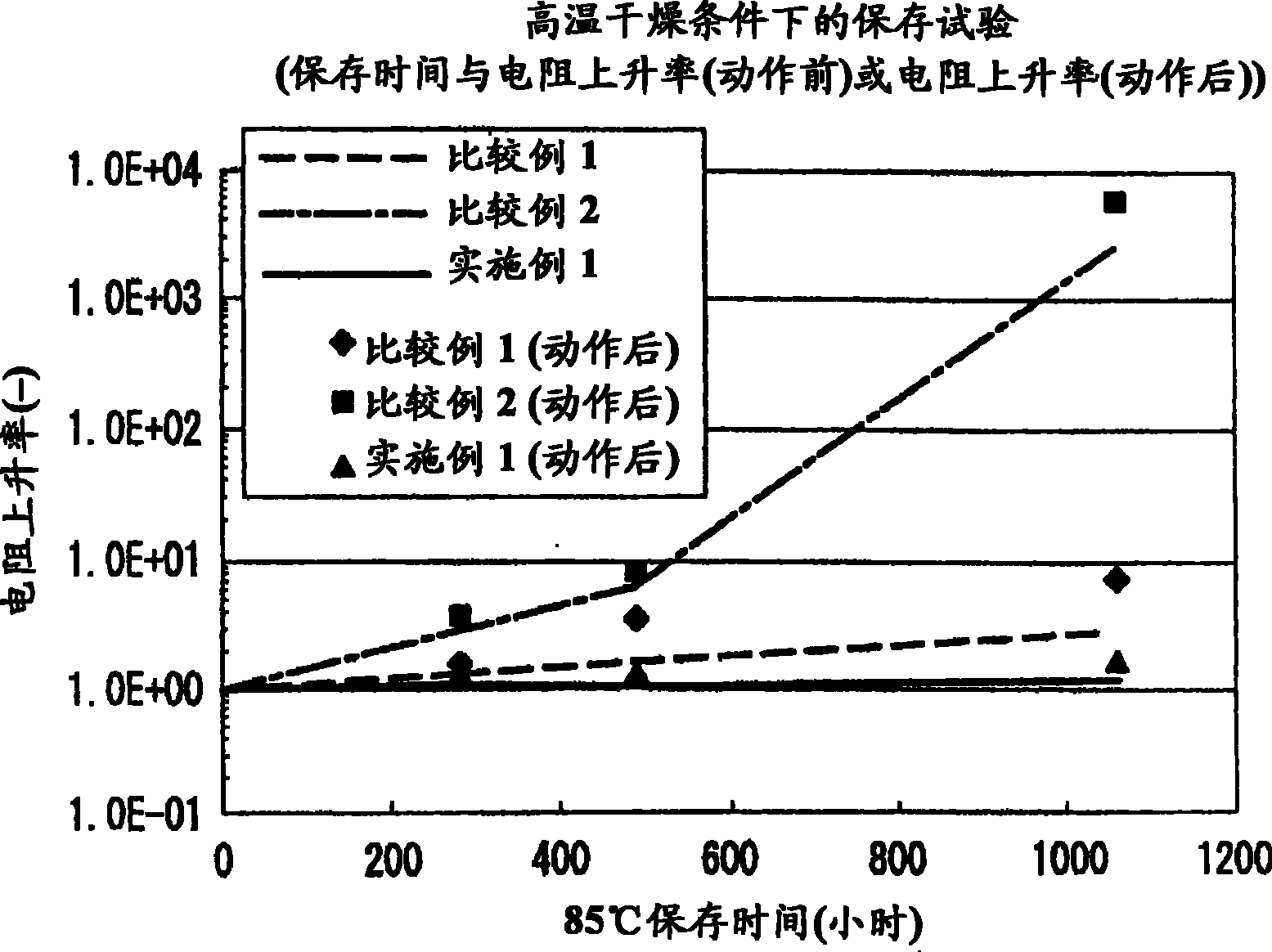

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below through the examples. This example is only a solution of the present invention, and the present invention is not limited by these examples.

[0073] As explained below, a PTC element was fabricated using a nickel-cobalt alloy filler as a conductive filler, polyethylene as a polymer material, and nickel metal foil as a metal electrode.

[0074] (1) Preparation of conductive filler

[0075] Heat 1125ml of sodium hydroxide aqueous solution containing tartaric acid to 85°C while stirring, add 19.5g of nickel chloride aqueous solution converted to metal Ni, and then add 89.1g of hydrazine as a sufficient reducing agent to reduce and precipitate Ni metal powder .

[0076] Next, an aqueous solution of cobalt chloride containing 3.9 g as cobalt metal and an aqueous nickel chloride solution containing 15.6 g as nickel metal were prepared. These solutions are mixed, added to the aqueous solution containing Ni metal powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com