Magnetic viscose fibre and its making method

A viscose fiber and manufacturing method technology, applied in the field of viscose fiber, can solve the problems of single fiber composition, insufficient additional function and value, single function, etc. The effect of functional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

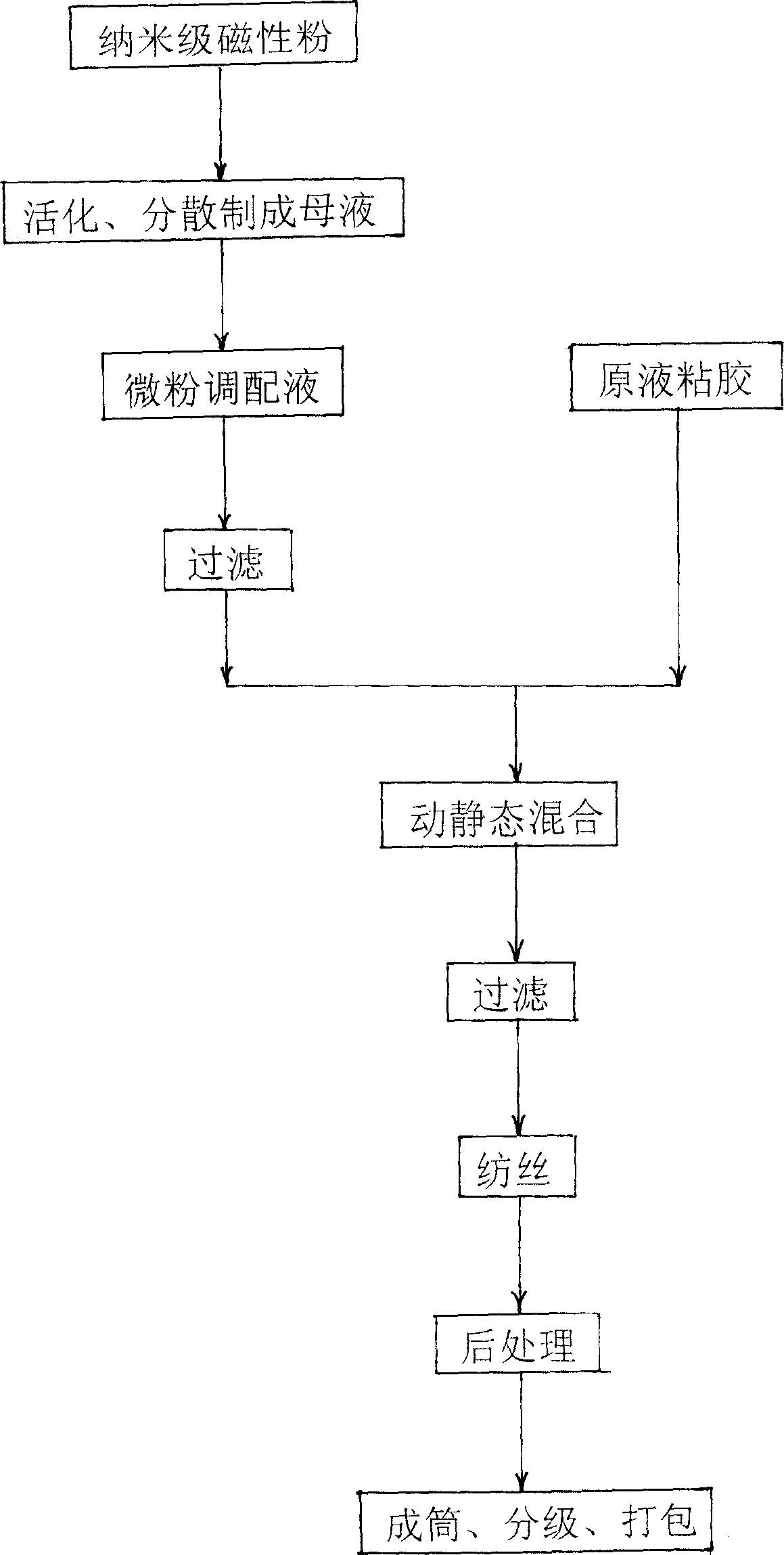

Method used

Image

Examples

Embodiment 1

[0037] Magnetic viscose fiber, the magnetic viscose fiber refers to the magnetic powder solution and viscose solution mixed at 0.1% and then spun to obtain the magnetic viscose fiber finished product with an average magnetic flux of the magnetic fiber greater than 0.38 mWeber. The magnetic powder is an inert acid and alkali-resistant nano-scale Fe3O4 magnetic powder after passivation treatment. The magnetic powder can also be replaced by acid and alkali resistant or inert nano-scale iron or nickel magnetic powder. The magnetic powder solution is a suspension formed by dispersing magnetic powder in ion-free water.

[0038] The manufacture method of magnetic viscose fiber is characterized in that: it is realized according to the following steps:

[0039] A, the preparation of magnetic powder mother liquor: press powder: the ratio of water=1: 1.5, the addition amount of dispersant is added by 0.5% of mother liquor made, and its configuration steps are:

[0040] (1) Put deionize...

Embodiment 2

[0056] The magnetic viscose fiber is characterized in that: the magnetic viscose fiber refers to the magnetic powder solution and the viscose solution mixed at 1.5% and then spun to obtain a finished magnetic viscose fiber with an average magnetic flux greater than 0.38 mWeber. The magnetic powder is an inert acid and alkali-resistant nano-scale Fe3O4 magnetic powder after passivation treatment. The magnetic powder can be replaced by acid and alkali resistant and inert nano-scale iron-based and nickel magnetic powder. Magnetic powder solution: a suspension formed by dispersing magnetic powder in deionized water.

[0057] The manufacture method of magnetic viscose fiber is characterized in that: it is realized according to the following steps:

[0058] A, the preparation of magnetic powder mother liquor: press powder: the ratio of water=1:5, the addition amount of dispersant is added by making 3% of mother liquor, and its configuration steps are:

[0059] (1) Put deionized wa...

Embodiment 3

[0075] Magnetic viscose fiber, said magnetic viscose fiber refers to the magnetic powder solution and viscose solution mixed at 1% and then spun to obtain a finished magnetic viscose fiber with an average magnetic flux greater than 0.38 mWeber. The magnetic powder: the main component is an inert acid and alkali-resistant nano-scale Fe3O4 magnetic powder formed through passivation treatment. The magnetic powder can be replaced by acid and alkali resistant and inert nano-scale iron-based and nickel magnetic powder. Magnetic powder solution is a suspension formed by dispersing magnetic powder in ion-free water.

[0076] The manufacture method of magnetic viscose fiber is characterized in that: it is realized according to the following steps:

[0077] A. Preparation of magnetic powder mother liquor: according to the ratio of powder: water = 1: 1, the amount of dispersant added is added by 1% of the mother liquor made, and the configuration steps are:

[0078] (1) Put deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com