Moving type quick automatic monitoring system for water quality

An automatic monitoring and mobile technology, applied in the direction of analyzing materials, sampling devices, instruments, etc., can solve the problems of high cost, restrictions on mobile monitoring, and a small number of fixed monitoring stations, and achieve broad application prospects and short measurement cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

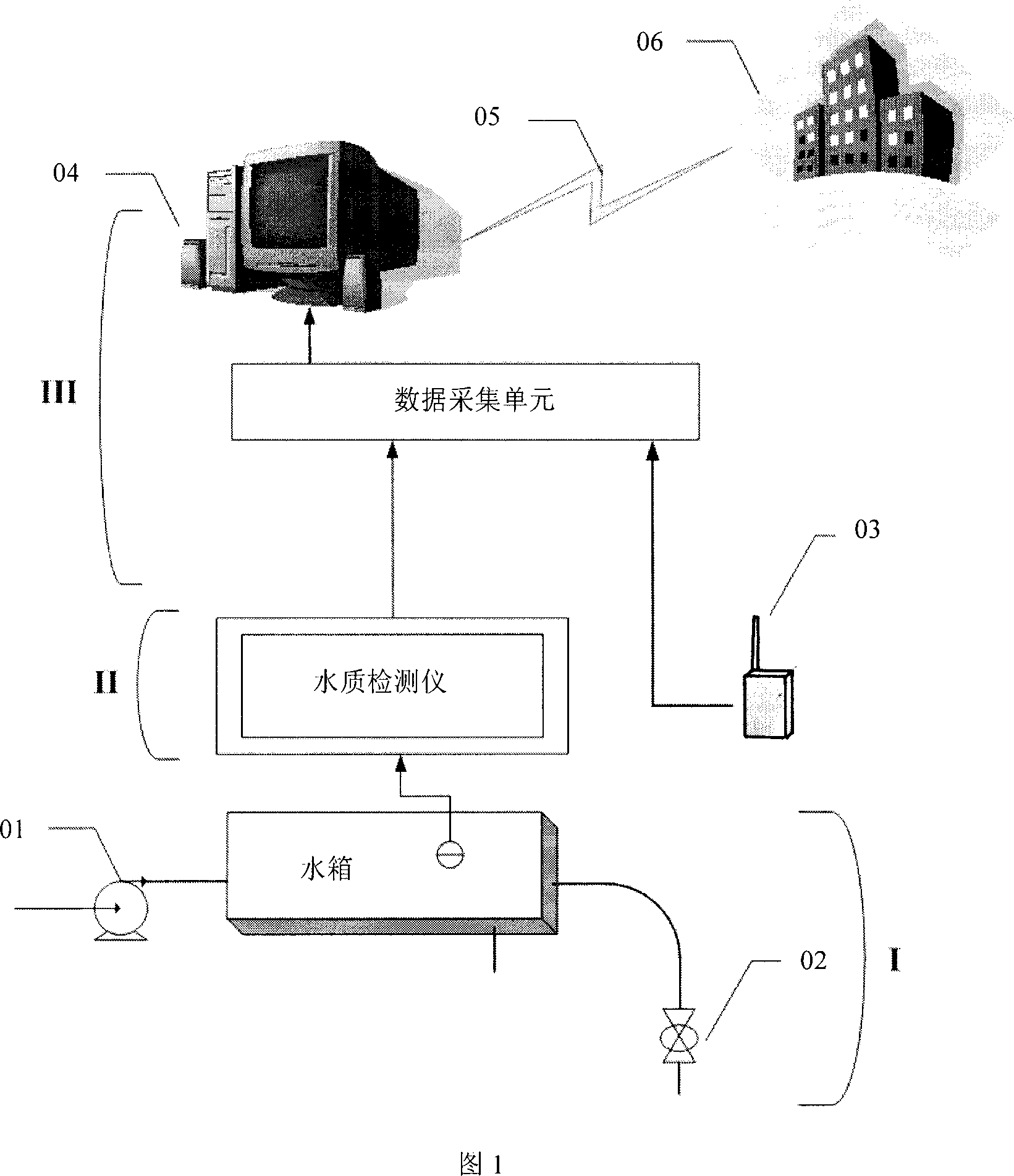

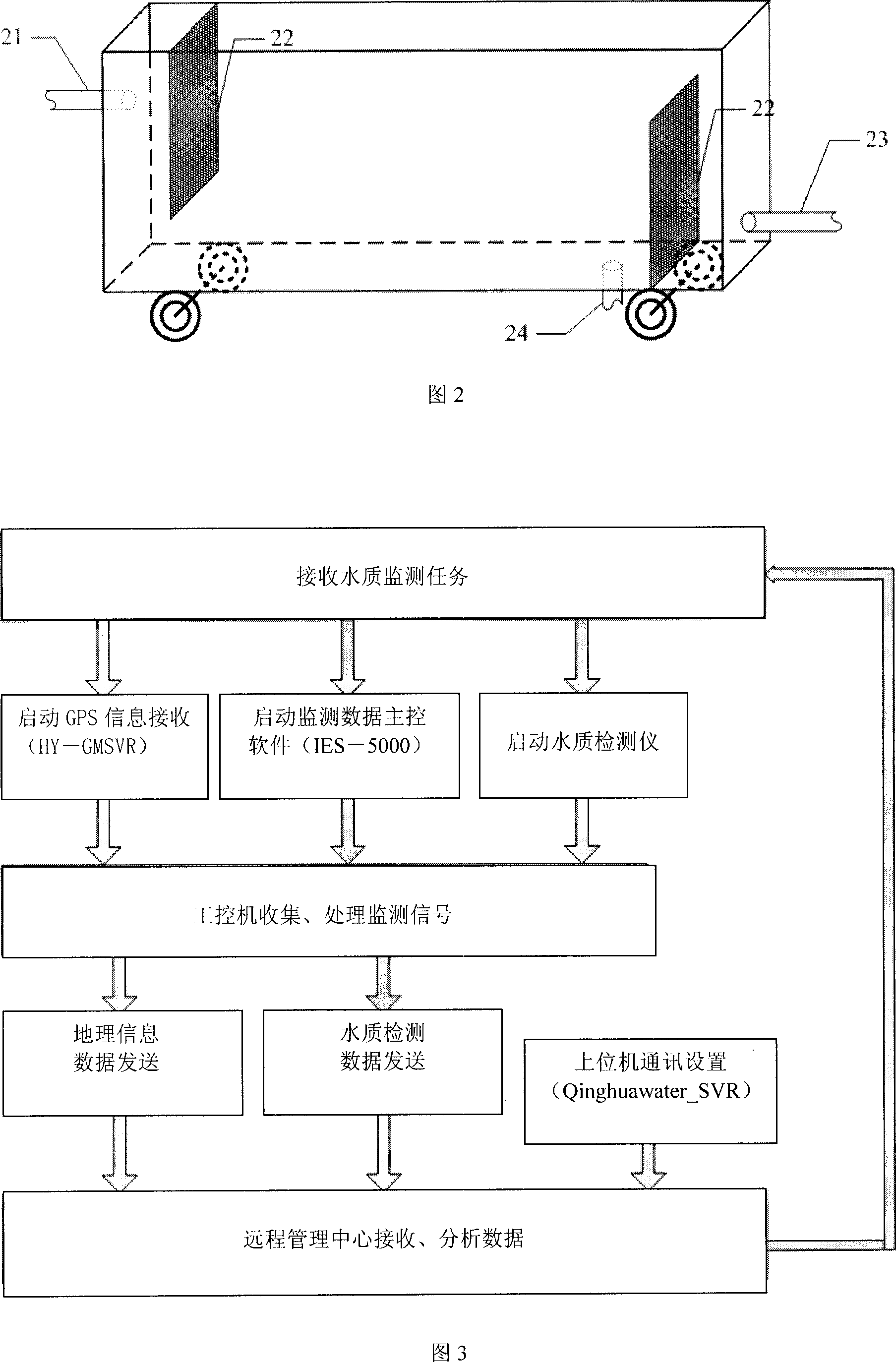

[0024] The composition of the mobile rapid water quality automatic monitoring system is shown in Figure 1. The whole system can be divided into three parts:

[0025] I sampling part: composed of self-priming pump 01 and water tank, 02 is the water outlet valve of the water tank; the sampling part is used to obtain stable surface water samples to be measured;

[0026] II monitoring part: composed of water quality detector and GPS receiver 03, to obtain water quality and geographic location data;

[0027] III Terminal processing part: Contains the data acquisition card, industrial computer 04, the data monitored by the water quality detector and the geographical location information received by the GPS receiver 03 are collected by the data acquisition unit, and then input into the computer for signal processing and storage, and the recorded The data is transmitted to the remote management center 06 through the GPRS wireless communication network 05.

[0028] When sampling the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com