Sterilizable flexible pouch package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

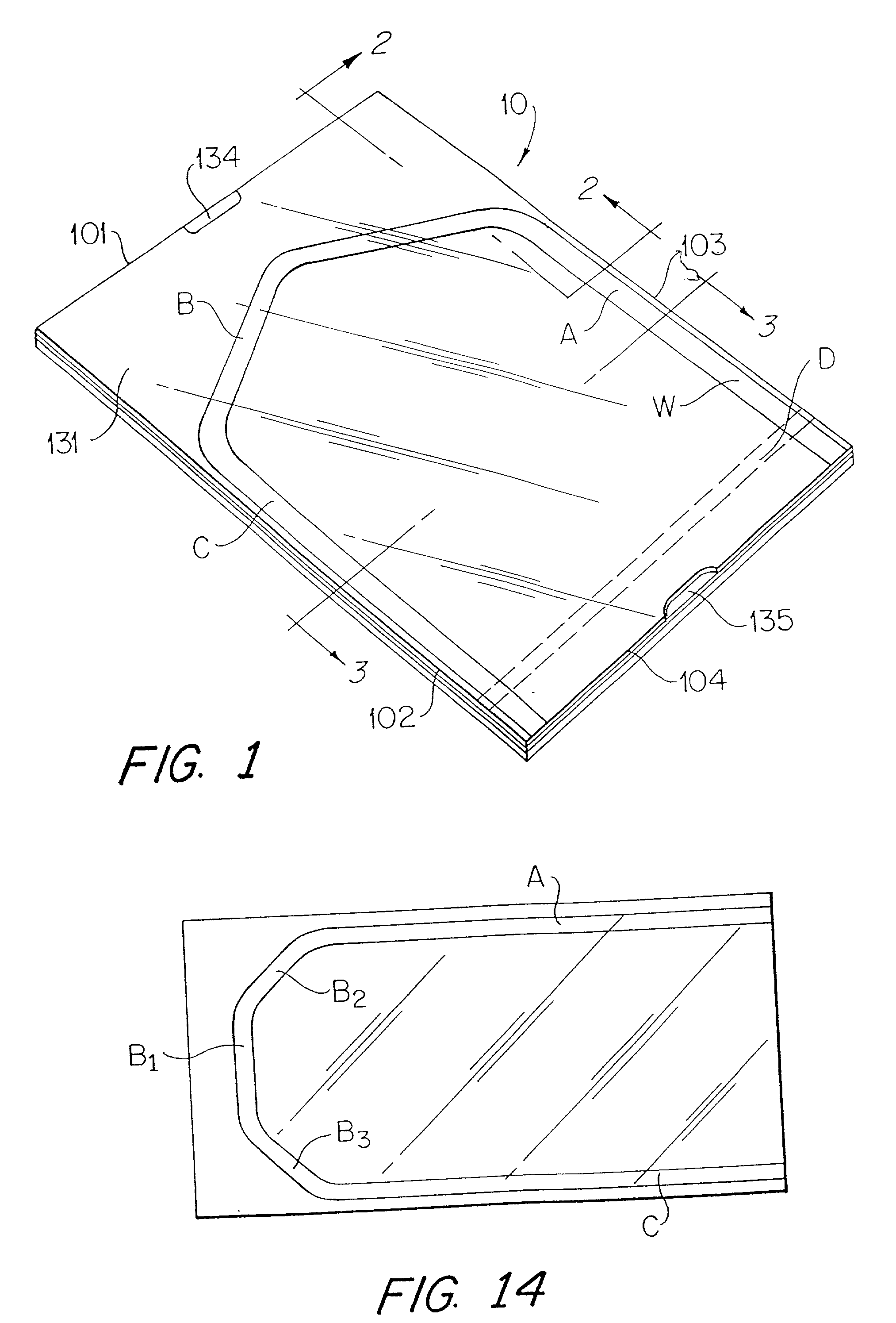

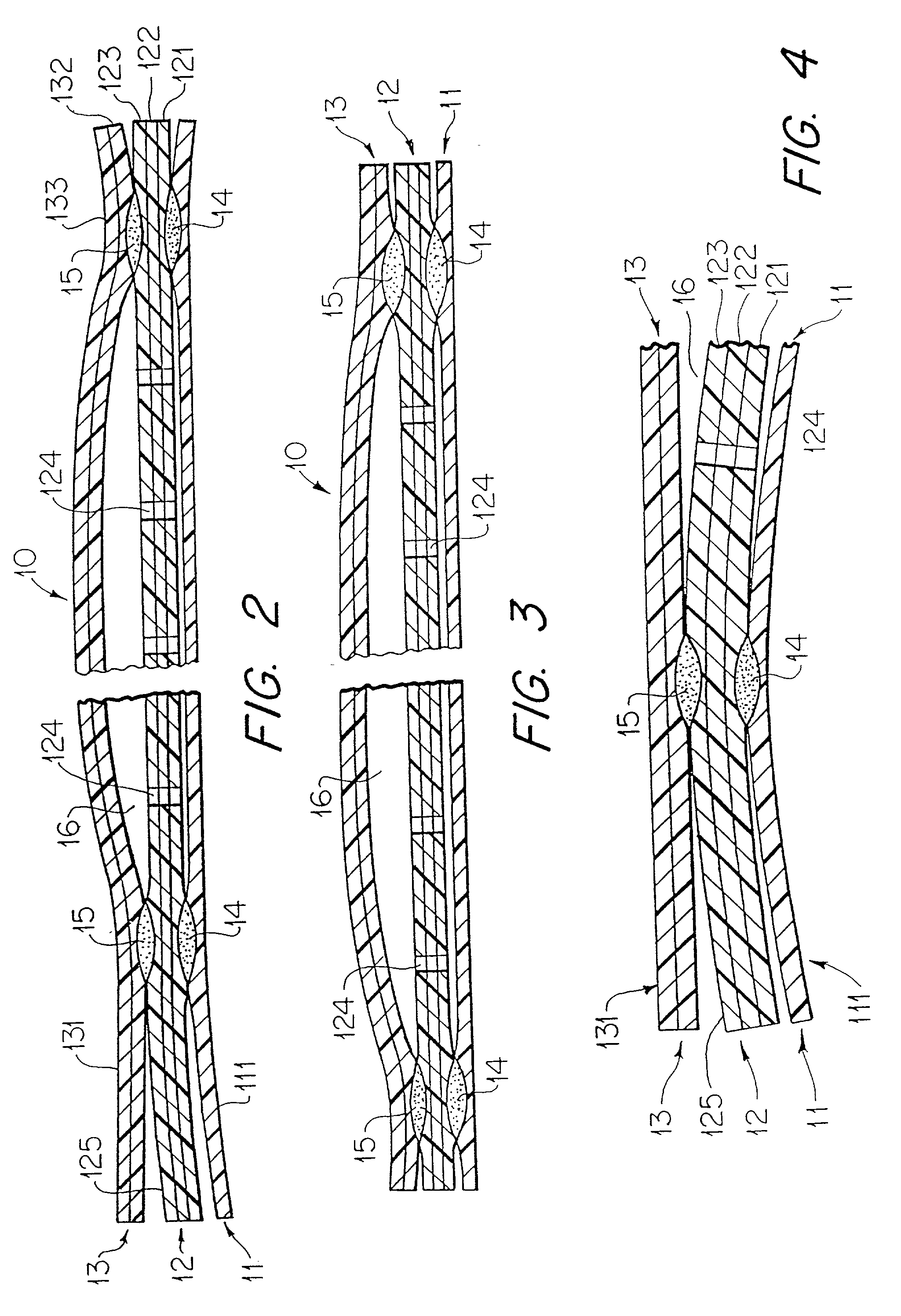

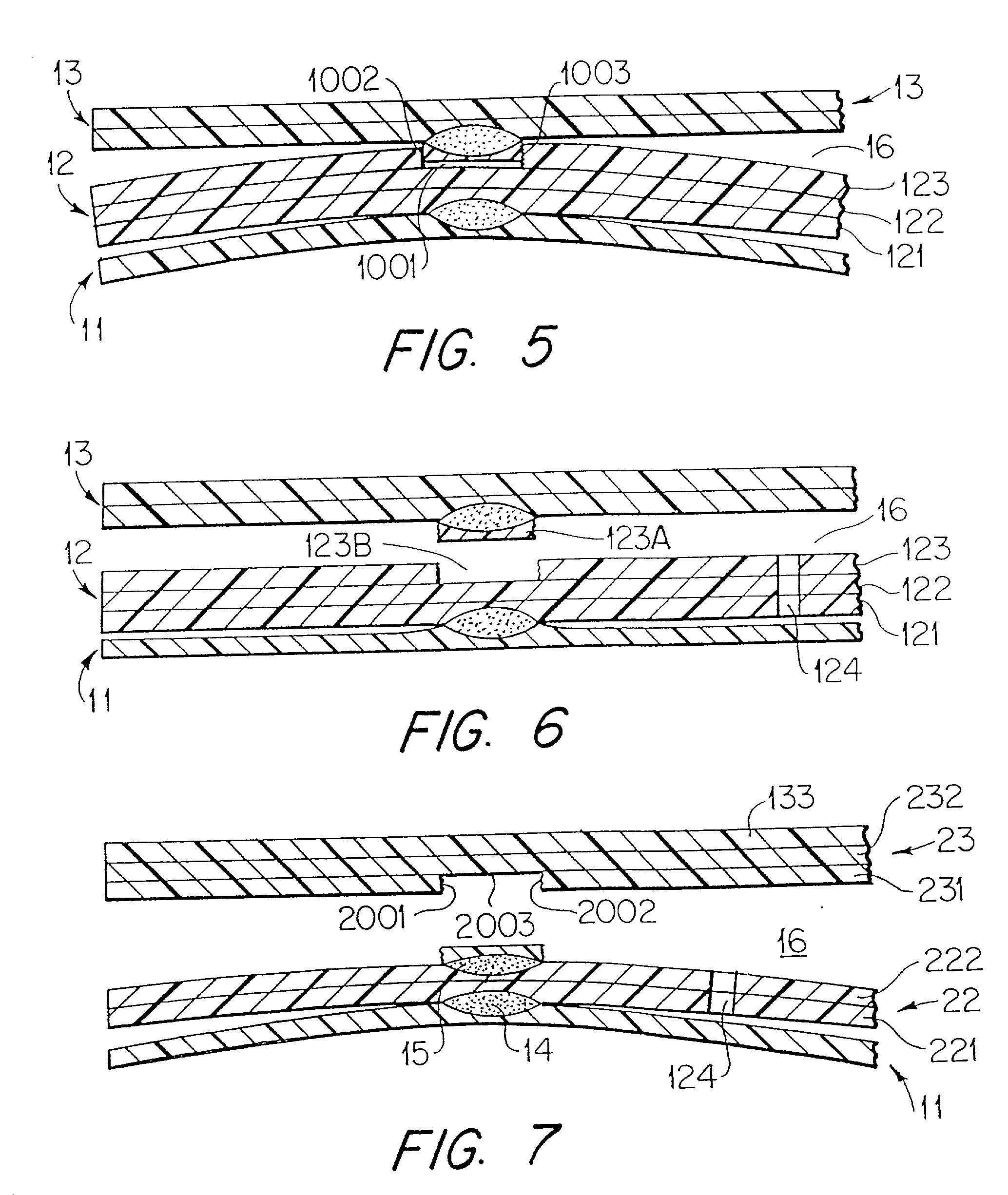

[0096] A plurality of pouch packages of the general type indicated in FIGS. 8-11 are fabricated by heat sealing three webs along a line heat seal in regions A, B and C. In each package, lower web 11' is "Securon", commercially available from the Fiberweb Group. The web is a drapable non-woven barrier fabric having a trilaminate structure with spunbonded polypropylene outer layers and an inner layer of melt blown polypropylene fibers, with a weight of 1.8 ounces per square yard. Web 11' is 163 / 4 inches in width and 303 / 4 inches in length. Intermediate web 12' is a three layer coextrusion having a bottom heat seal layer 121 for forming a permanent line heat seal 14 with the non-woven barrier fabric web, a top heat seal layer 123 for forming a permanent line heat seal 15 with upper web 13', and a core layer 122 bonded to heat seal layers 121 and 123 and which delaminates from upper heat seal layer 123 in the area of permanent line heat seal 15 when the heat-sealed package is peeled ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com