Hybrid vehicle and process for operating a hybrid vehicle

a hybrid vehicle and hybrid technology, applied in hybrid vehicles, process and machine control, instruments, etc., can solve the problems of increasing the cost and increasing the space requiremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

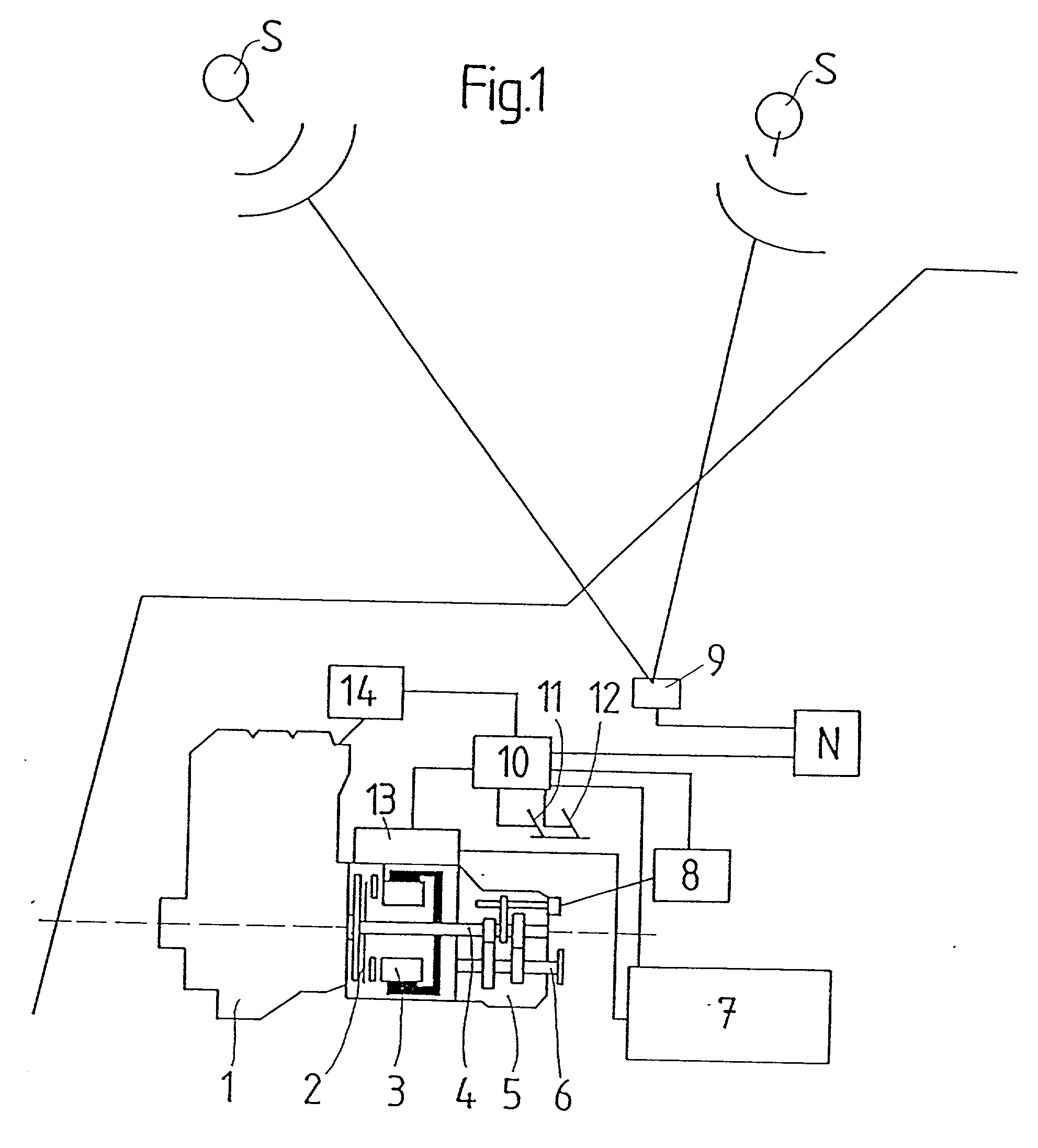

[0027] A hybrid drive according to an embodiment of the present invention includes an internal combustion engine 1 having an average output, an electric motor 3 connected to the internal combustion engine 1 via a coupling 2, and a transmission 5 flanged to the electric motor 3. The transmission 5 includes a transmission input shaft 4 and a transmission output shaft 8. An electric energy storage device 7 is connected via an intermediate connection of a power electronics system 13 to the electric motor 3 for driving the electric motor 3 with low work and high output. A vehicle computer 10 is connected to the power electronics system 13, the electric energy storage device 7, the accelerator pedal 11 and the brake pedal 12, and a motor electronics system 14 for controlling the internal combustion engine 1. The vehicle computer 10 also controls the electric motor 3 via the power electronics system 13. A transmission control 8 is also connected to the computer 10 for controlling the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com