Electronic pressure-sensitive device for detecting the magnitude of load as electrical resistance

a technology of electrical resistance and electronic pressure, which is applied in the direction of instruments, pedestrian/occupant safety arrangements, force/torque/work measurement apparatus, etc., can solve the problems of high cost, difficult to detect a small load applied to the electronic pressure-sensitive device or a variation of load, and the inability to sense the physique of the person sitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

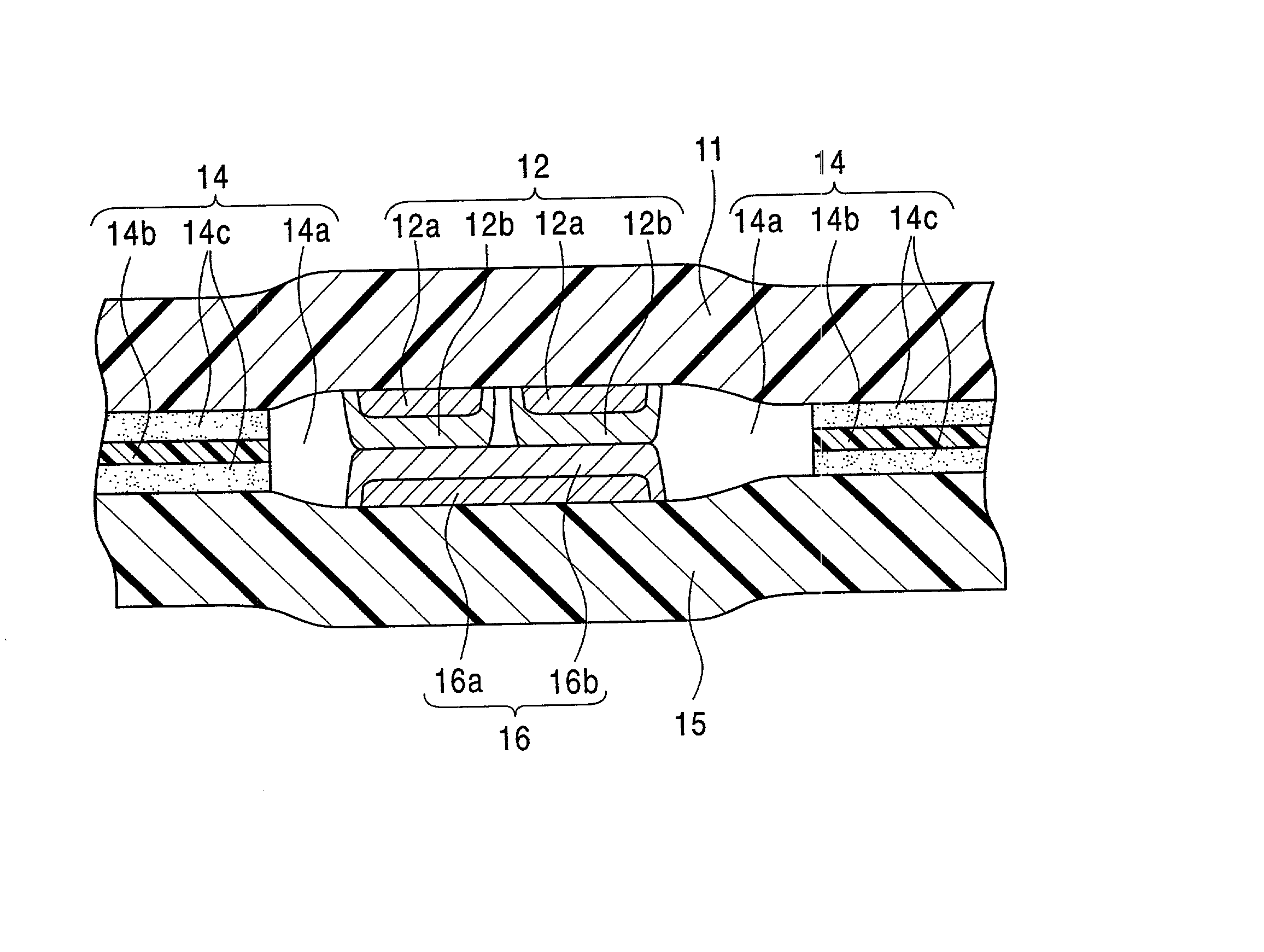

[0079] FIG. 5 is a sectional view of an electronic pressure-sensitive device as a comparative example.

[0080] Like the embodiments of the present invention, the comparative example comprises first and second substrates 21 and 25, and first and second contact portions 22 and 26 formed on the first and second substrates 21 and 25 and opposed to each other. The first and second contact portions 22 and 26 are of a double layer structure, consisting of first and second conductor layers 22a and 26a and first and second resistive element layers 22b and 26b. The first resistive element layer 22b and the second resistive element layer 26b are opposed to each other through the intermediation of a gap S as long as no load is applied to the substrates 21 and 25, the width of the gap S being maintained by the thickness dimension of a spacer 24 provided between the first and second substrates 21 and 25.

[0081] Next, the load-resistance characteristics of the electronic pressure sensitive device of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com