Wiring substrate, wiring board, and wiring substrate mounting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following experiments were conducted in order to confirm the effect of the present invention.

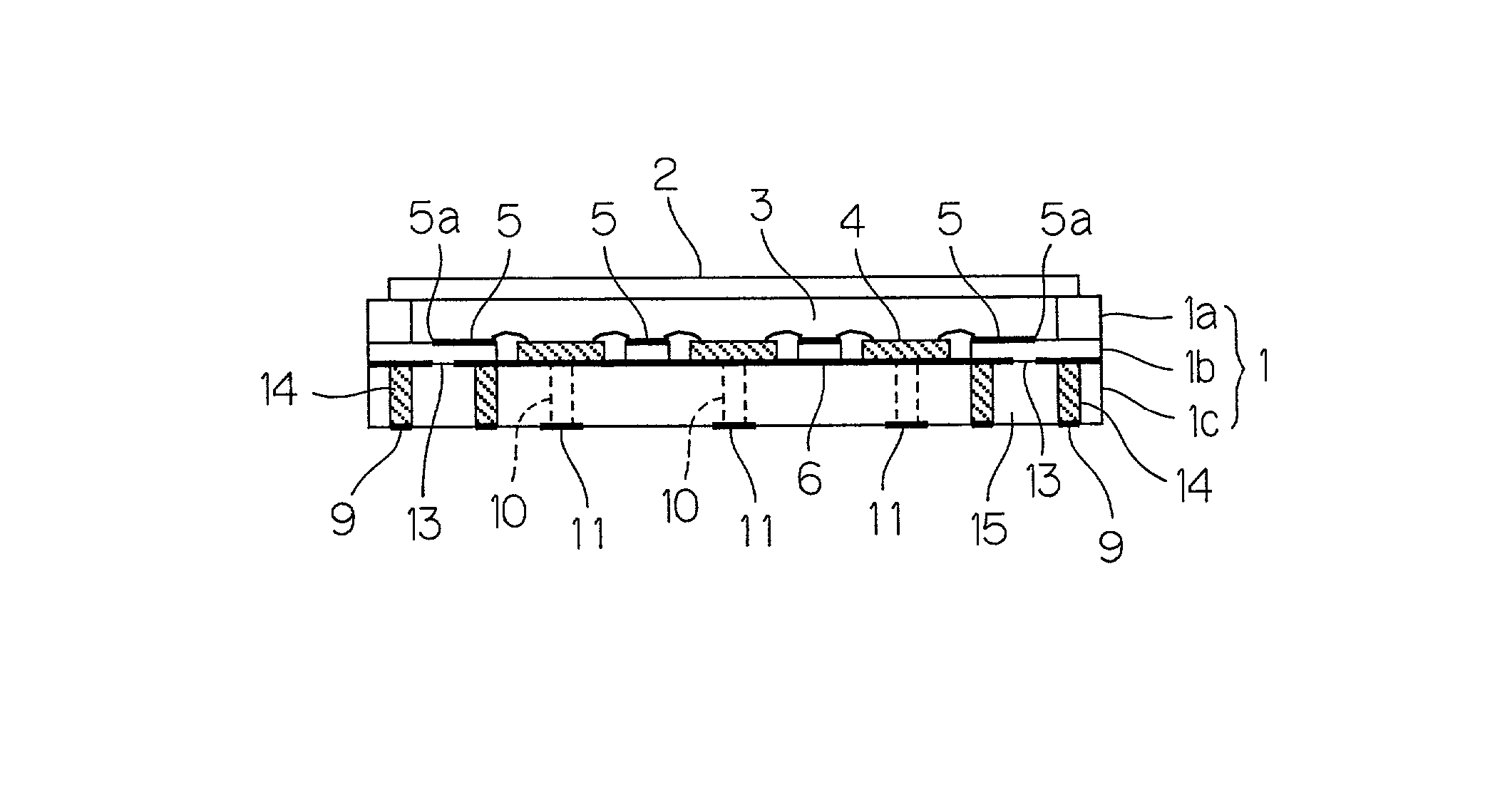

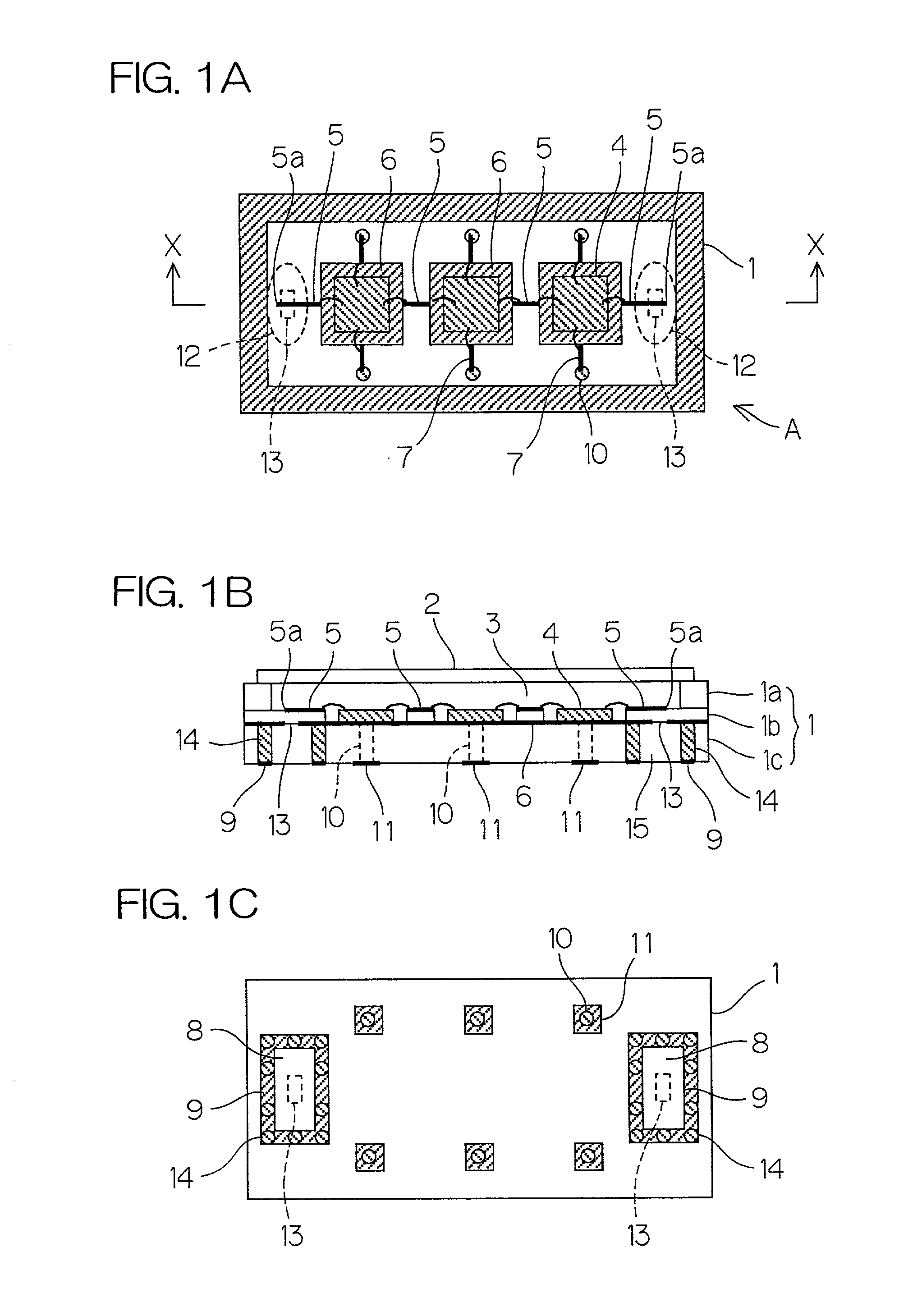

[0061] First, as a wiring substrate A, a substrate for evaluation which is similar to the wiring substrate A shown in FIG. 1 was fabricated by a normal stacking and simultaneous sintering technique using a green sheet composed of alumina ceramics (if the green sheet is sintered, the dielectric loss tangent at a frequency of 10 GHz is 0.0006) and tungsten metallized ink.

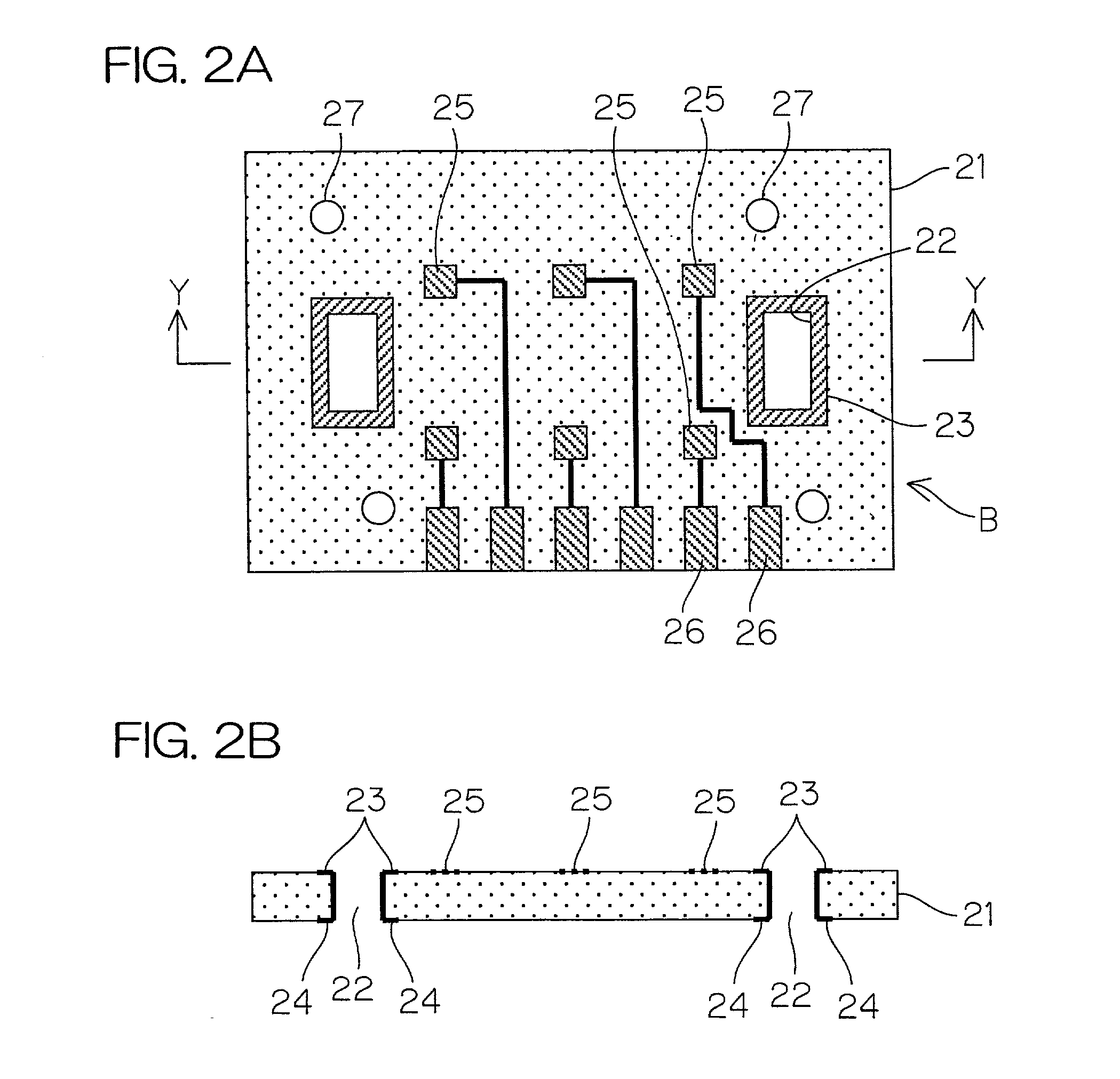

[0062] In the substrate for evaluation, there is no cavity in the wiring substrate A shown in FIG. 1, no high frequency component is carried thereon, and two microstrip lines each having an opened terminal end for input and output signals are connected to each other. An example of a matching section was one having a structure of a microstrip line 5, a slot hole 13, and a matching section 15 as shown in FIGS. 1A to 1C. After sintering, metallized surfaces of a surface and a reverse surface of a dielectric substrate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com