Soy protein products and methods for producing soy protein products

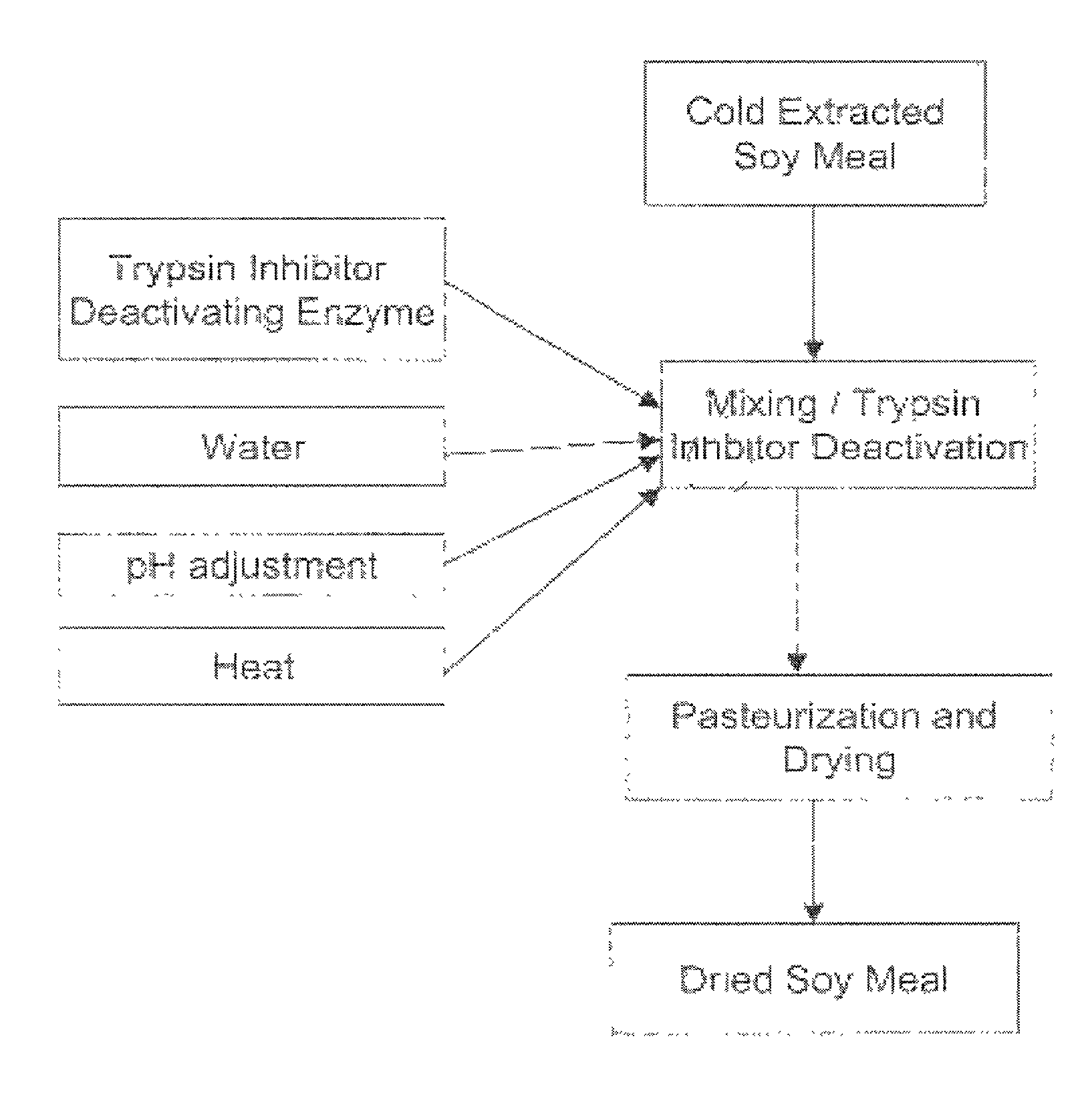

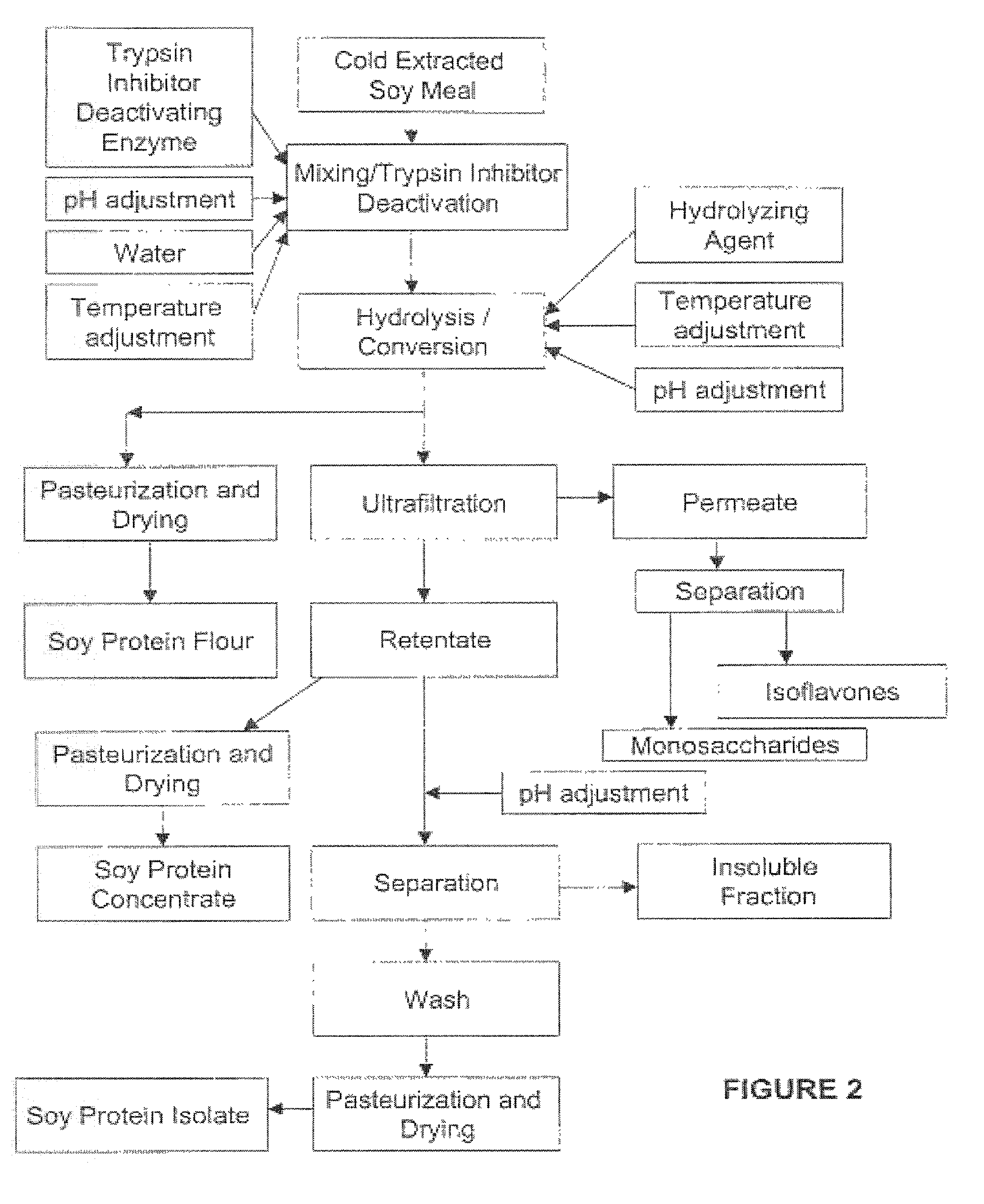

a technology of soy protein and products, applied in the field of soy products, can solve the problems of reducing the digestibility of other proteins, the increase of the pancreas beyond its normal size, and the dramatic decrease in the ability to digest proteins, so as to maximize the deactivation of trypsin inhibitors, the effect of reducing the molecular weight and being easy to diges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example # 1

EXAMPLE #1

[0042] The following example shows the effectiveness of the invention. A test was performed to evaluate the effectiveness of the process. Soy meal, defatted according to the method of U.S. Pat. No. 5,707,673 and using propane as the oil-extractant was mixed with water and proteolytic enzyme in the following amounts:

1 Ingredient Amount (grams) Defatted Soy Meal 100.00 Water 200.00 ALCALASE 2.4 enzyme 0.6 Alpha-galactosidase enzyme 1.0 TOTAL 301.6

[0043] The ingredients were mixed into a Hobart 5 quart container and mixed for 5 minutes. The mixture was incubated at 50.degree. C. in an oven. Samples were taken every 30 minutes and tested for Urease activity. When the Urease activity reached a level of less than 0.2 pH increase between measurements, the incubation was stopped, and the samples were frozen and analyzed by Ralston Analytical Laboratories of St. Louis, Mo. As shown in the results, toasted soy meal is soy meal treated with heat to deactivate the trypsin inhibitors. ...

example # 2

EXAMPLE #2

[0044] Soy meal, defatted according to the method of U.S. Pat. No.: 5,707,673 and using propane as the oil-extractant was treated as follows. 5.5 kilograms of soy meal was mixed with 22 liters of water. The pH of the resulting slurry was adjusted to 8.0 using sodium hydroxide. The mixture was then wet-milled using a Fryma wet mill. The soy meal slurry was heated to about 50.degree. C. to 55.degree. C. and diafiltrated for about an hour over an ultra-filtration membrane having a molecular weight cut-off of about 9,000. Approximately 22 grams of PROTAMEX MG enzyme complex was then added to the slurry to deactivate the naturally-occurring trypsin inhibitors. The PROTAMEX MG treatment continued for about 3 hours, during which time the pH of the slurry dropped from 8.0 to about 7.0 and the .degree.Brix increased from 15.6 to about 16.6.

[0045] The pH of the slurry was then decreased to about 5.0 with hydrochloric acid, and 22 grams of ALPHA-GAL 600 AND 11 grams of VISCOZYME L we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com