Expanded full-fat soybean processing technology improving protein solubility

A technology of puffed full-fat soybeans and processing technology, applied in the fields of application, animal feed, animal feed, etc., can solve the problems of hindering the digestion, absorption and utilization of nutrients, reducing the growth performance of livestock and poultry, affecting the utilization of soybeans, etc., and achieving low urease Activity, nutritional value enhancement, water content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

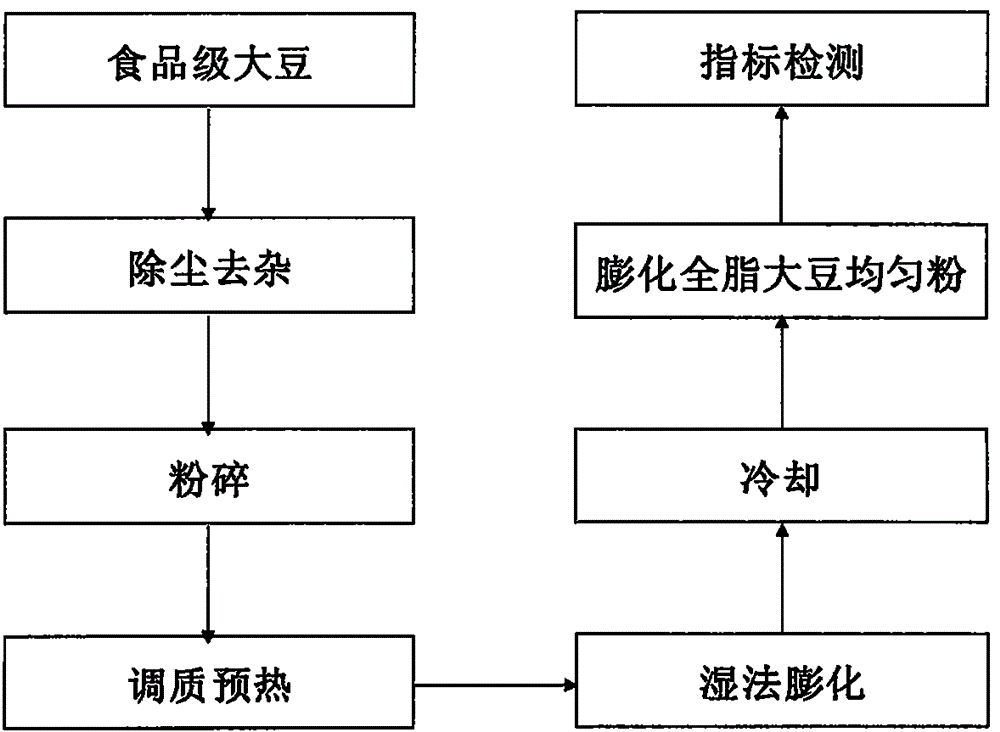

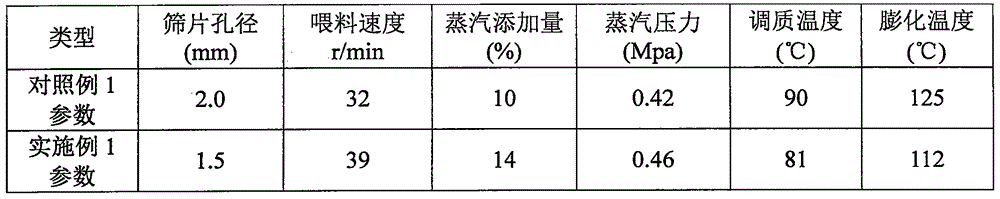

[0014] A processing technology of puffed full-fat soybeans with improved protein solubility, the production flow chart of which is as follows figure 1 Shown: Food-grade soybeans (in terms of weight percent, formula is: 30wt% of American West soybeans and 70wt% of Henan soybeans, formula crude fat theoretical value 17.85%, crude protein theoretical value 34.6%) are dedusted and impurity removed, and sent into Grinding in a pulverizer, the pulverized material is sent to a wet extruder (260-type single-screw extruder, produced by Guangzhou Tiandi) for conditioning, preheating, extruding and puffing, and finally cooled to room temperature to obtain puffed full-fat soybeans; , the sieve aperture of the pulverizer is 1.5mm during pulverization, and the process parameters of the wet extruder: feeding speed 39r / min, steam addition 14%, steam pressure 0.46Mpa, conditioning temperature 81°C, conditioning time 120s, The puffing temperature is 112°C and the puffing time is 15s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com