Method for improving acid proteinase activity of soy yeast

An acid protease, Daqu technology, applied in the direction of food ingredients containing natural extracts, food ingredients containing inorganic compounds, food preparation, etc., can solve problems such as poor economic benefits, environmental pollution, waste of resources, etc. The effect of promoting secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Preparation of tomato pomace extract, inorganic salt mixture and seed koji

[0017] Preparation of tomato pomace extract: tomato pomace obtained from tomato juice or tomato paste manufacturers, dried in vacuum microwave until water content <5%, crushed through 80-mesh sieve, then extracted with 20 times mass ratio aqueous solution at 90°C for 2 hours , and filtered to obtain the extract.

[0018] Preparation of inorganic salt mixture: weigh 70mg CuSO 4 ·5H 2 O, 50mg ZnSO 4 ·7H 2 O, 75mg FeSO 4 ·7H 2 O, 50mg KH 2 PO 4 Dissolve in 100mL of 0.2M hydrochloric acid solution.

[0019] Preparation of seed koji: Aspergillus oryzae Huyao 3.042 is used to prepare seed koji. The number of koji spores should be more than 5 billion per gram of koji (dry basis), and the germination rate of spores should not be lower than 90%.

Embodiment 2

[0021] (1) Take a certain amount of soybeans to remove impurities, weigh them, soak them, and then steam them at 0.12MPa for 8 minutes.

[0022] (2) Add pantothenic acid equivalent to 0.10% of soybean weight to the cooked soybeans, mix well with 3% tomato pomace extract, 1.25% inorganic salt mixture, 20% flour and 0.3% seed koji After that, send it into the Quchi and spread it loosely;

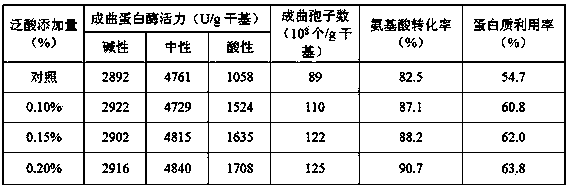

[0023] (3) The temperature in the bending room is controlled at 28-30°C, the relative humidity is controlled at 90-95%, and the product temperature is controlled at 32-34°C by intermittent ventilation. Spraying concentration is 5% pantothenic acid aqueous solution, carry out two turnings in total. After 48 hours of koji making, the koji was released, and its acid protease activity reached 1524U / g.

[0024] (4) Add brine to the finished koji in proportion and pump it into the fermentation tank to brew soy sauce by high-salt solid-state method. The protein utilization rate of soy sauce raw mat...

Embodiment 3

[0026] (1) Take a certain amount of soybeans to remove impurities, weigh them, soak them, and cook them at 0.16MPa for 5 minutes under pressure.

[0027] (2) Add pantothenic acid equivalent to 0.15% of soybean weight to the cooked soybeans, mix with 5% tomato pomace extract, 1.25% inorganic salt mixture, 25% flour and 0.5% seed koji After that, send it into the Quchi and spread it loosely;

[0028] (3) The temperature in the bending room is controlled at 28-30°C, the relative humidity is controlled at 90-95%, the temperature of the ventilation control product is 32-34°C, and the bending is performed when cracks appear on the surface of the bending material. Spray concentration is 5% pantothenic acid aqueous solution, carry out two times of song turning altogether. After 44 hours of koji making, the koji was released, and its acid protease activity reached 1635U / g.

[0029] (4) Add brine to the finished koji in proportion and pump it into the fermentation tank to brew soy sau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com