Inflatable insulating liners including phase change material

a technology of phase change material and insulating liners, which is applied in the direction of cooling fluid circulation, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of time-sensitive, perishable foodstuffs, and relatively slow surface transportation, so as to reduce the number of welding passes required, improve manufacturing efficiency, and reduce spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

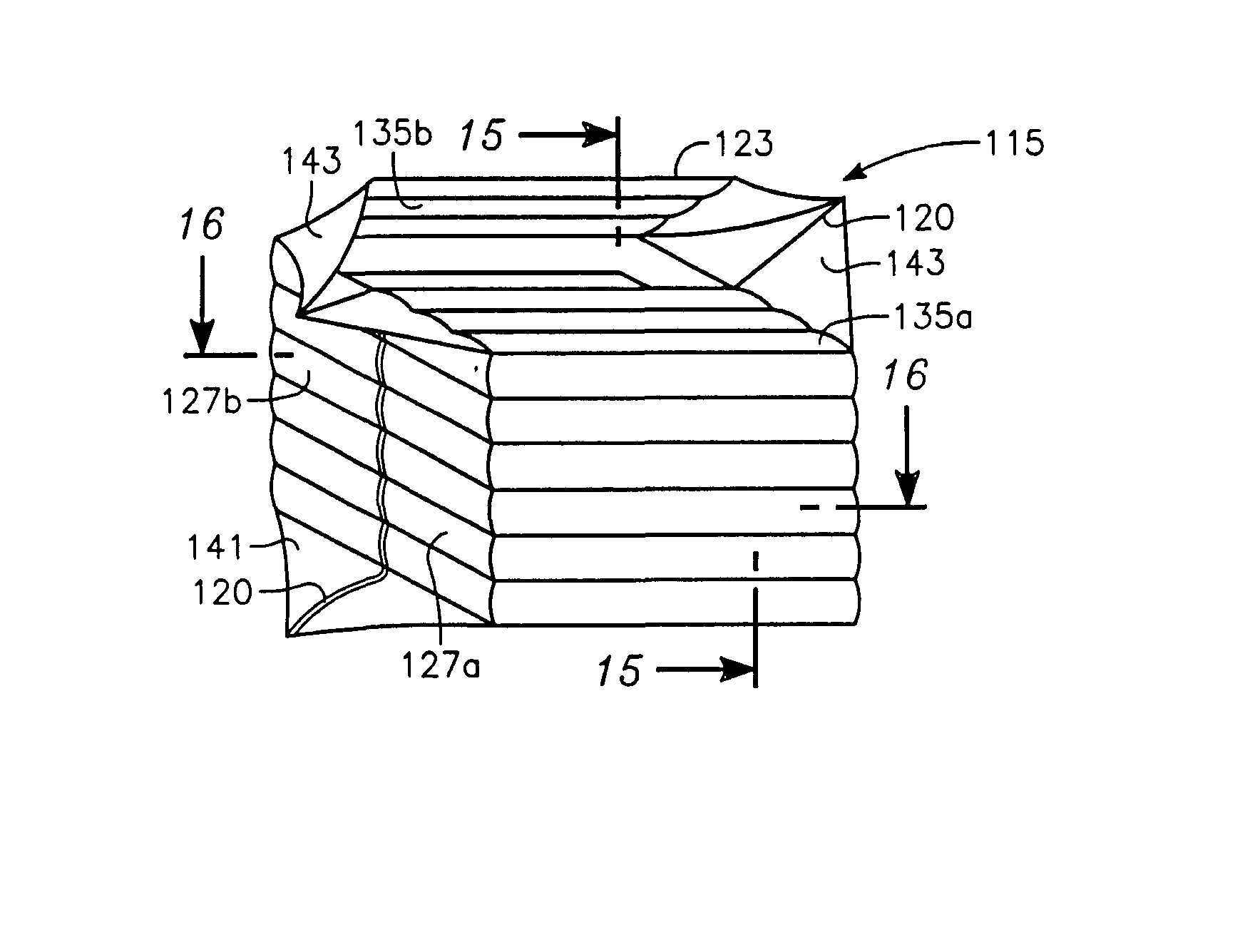

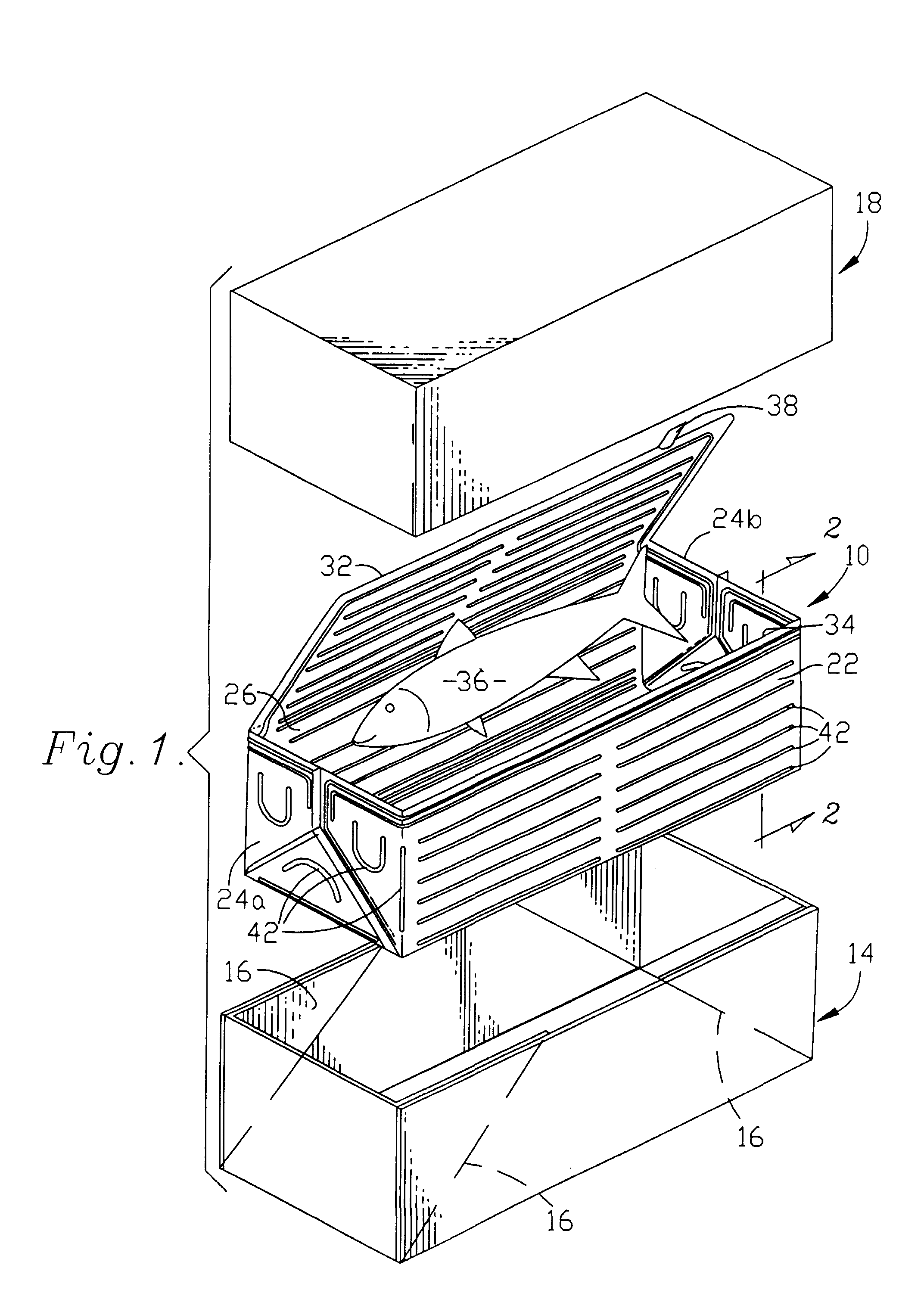

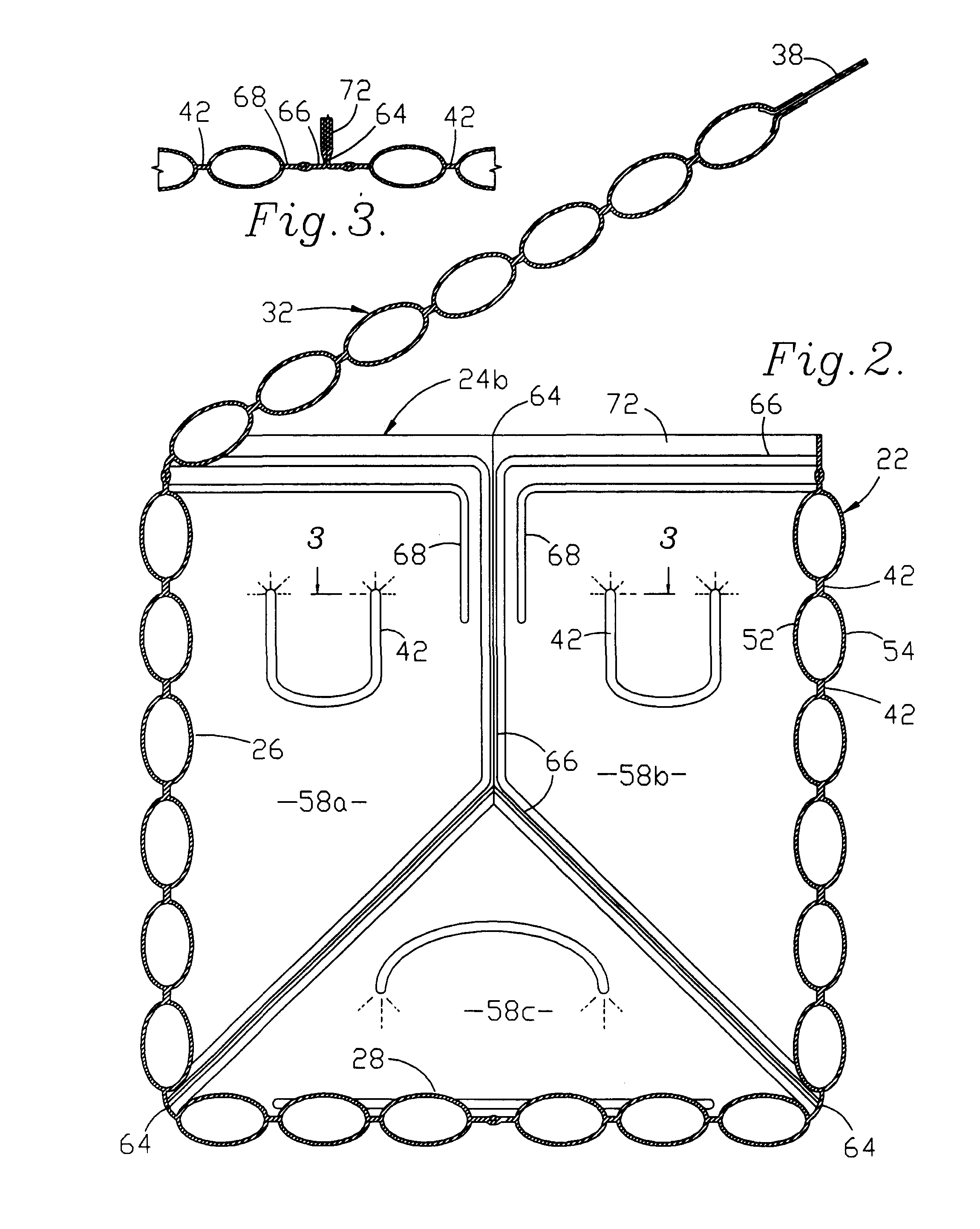

[0032] Reference is now made to the drawings wherein like numerals refer to like parts throughout. An inflatable insulating shipping box liner10 is depicted in Figure1 as received within a transport box bottom 14. A pair of gussets 16 formed at each end of the transport box bottom 14 are preferably provided to minimize the likelihood of any liquid leakage from within the transport box bottom 14.

[0033] A transport box top 18 is received by the transport box bottom 14 in a fully telescoping manner, again minimizing the opportunity for the leakage of liquid from the contents carried within the transport box. Additionally, in a conventional manner the transport box bottom and top 14, 18 are both waxed to preserve their structural integrity against damage caused by liquids that have either leaked from the interior insulating shipping box liner or from liquids wetting an outer surface or surfaces thereof.

[0034] The inflatable insulating shipping box liner 10 includes a front wall 22 a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com