Odor control cassette

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

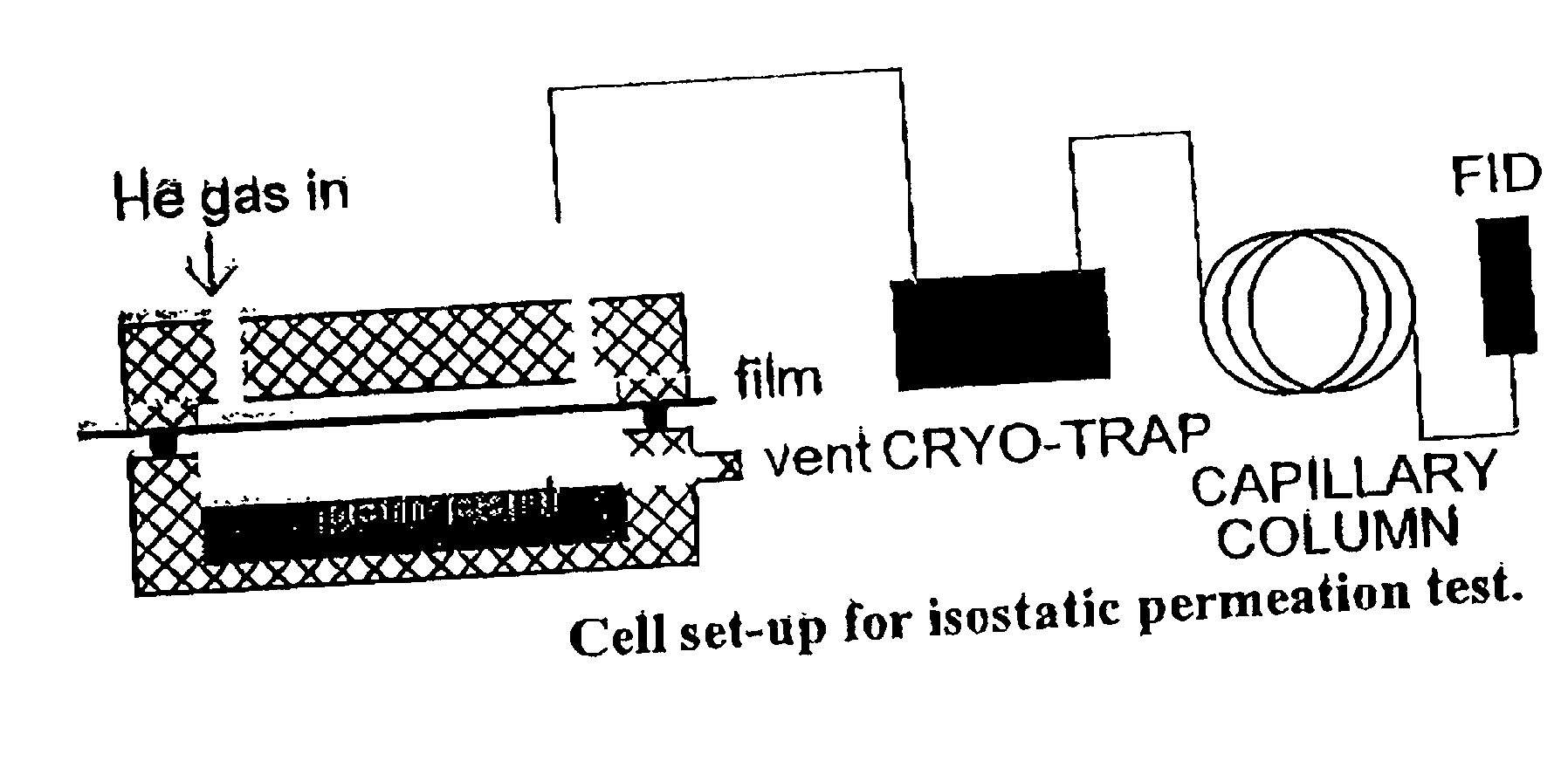

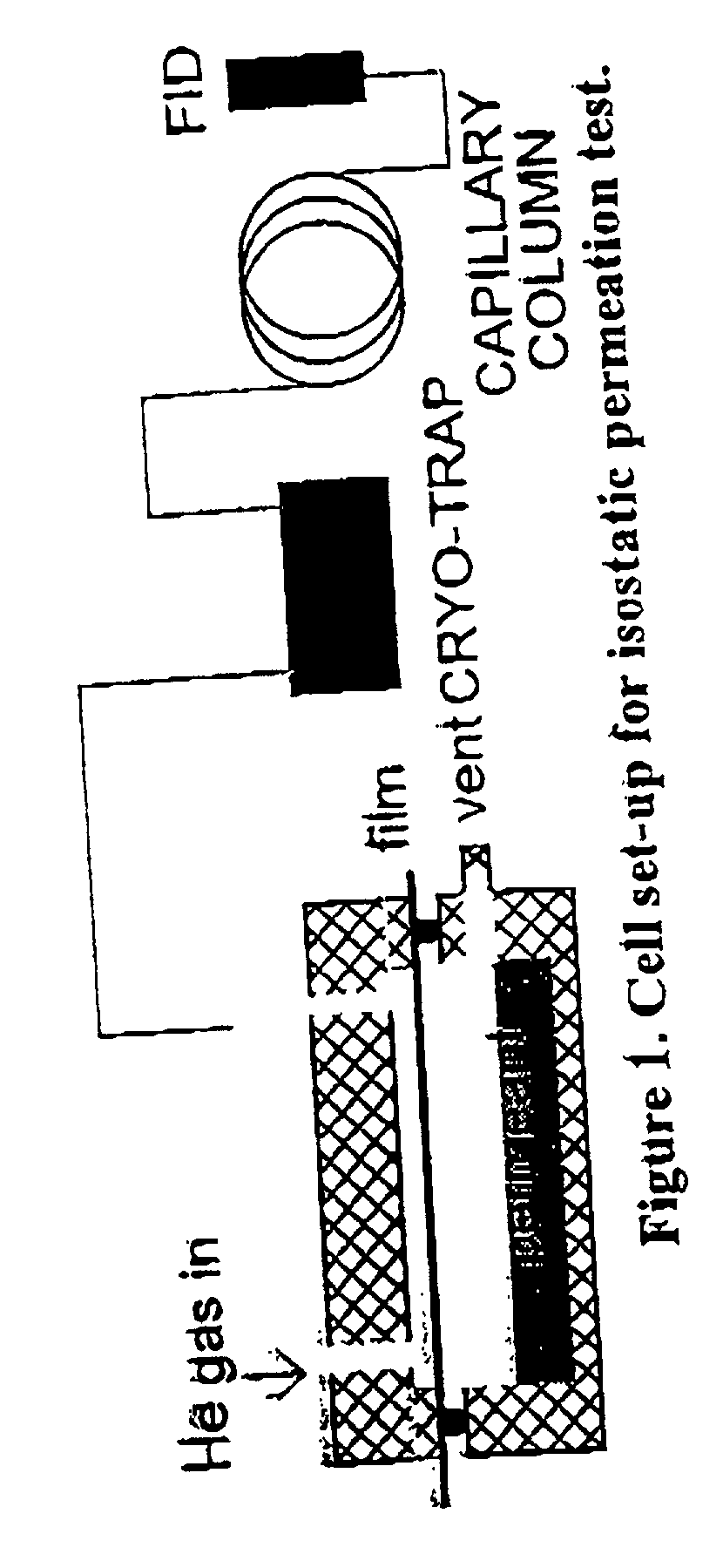

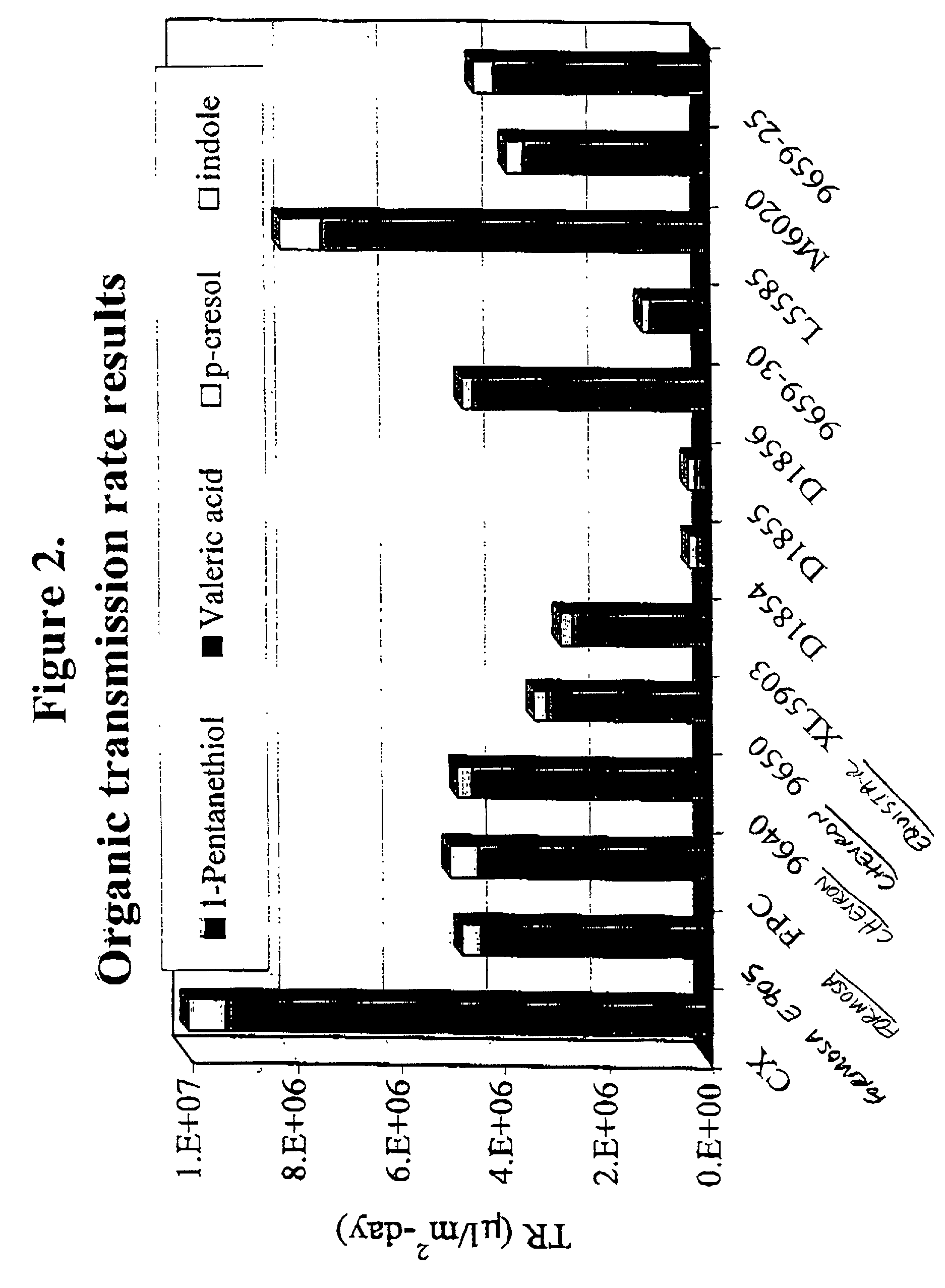

[0023] An organic permeation study was undertaken to provide barrier characteristics of various films for human fecal matter. This data was developed by performing an isostatic transmission rate study.

[0024] The organic compounds shown in Table 1 were combined in equal amounts by volume. The multi-component mixture and the films were placed in a remote cell as illustrated in FIG. 1. The top sides of the films were continuously swept with a nitrogen carrier gas in order to prevent any decrease in concentration gradient across the film.

3TABLE 1 Table 1 shows the organic permeants used for the permeation study. COMPOUND CLASS 1-Pentanethiol C5 mercaptan Valeric acid C5 organic acid p-cresol Substituted phenol Indole Aromatic heterocycle

[0025] The carrier gas stream was periodically monitored to determine whether equilibrium had been reached. Once equilibrium was achieved, the results were recorded. A MOCON ARMATRAN II equipped with a capillary column and a flame ionization detector (FI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com