Highly branched polymer from telomerization

a polymer and telomerization technology, applied in the field of high-branched polymers and copolymers, can solve the problems of unfavorable industrial production of living polymerization processes, unenvironmental and practical use of heavy metal containing inorganic salts in atom transfer radical polymerization, and the disadvantages of polymerization processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

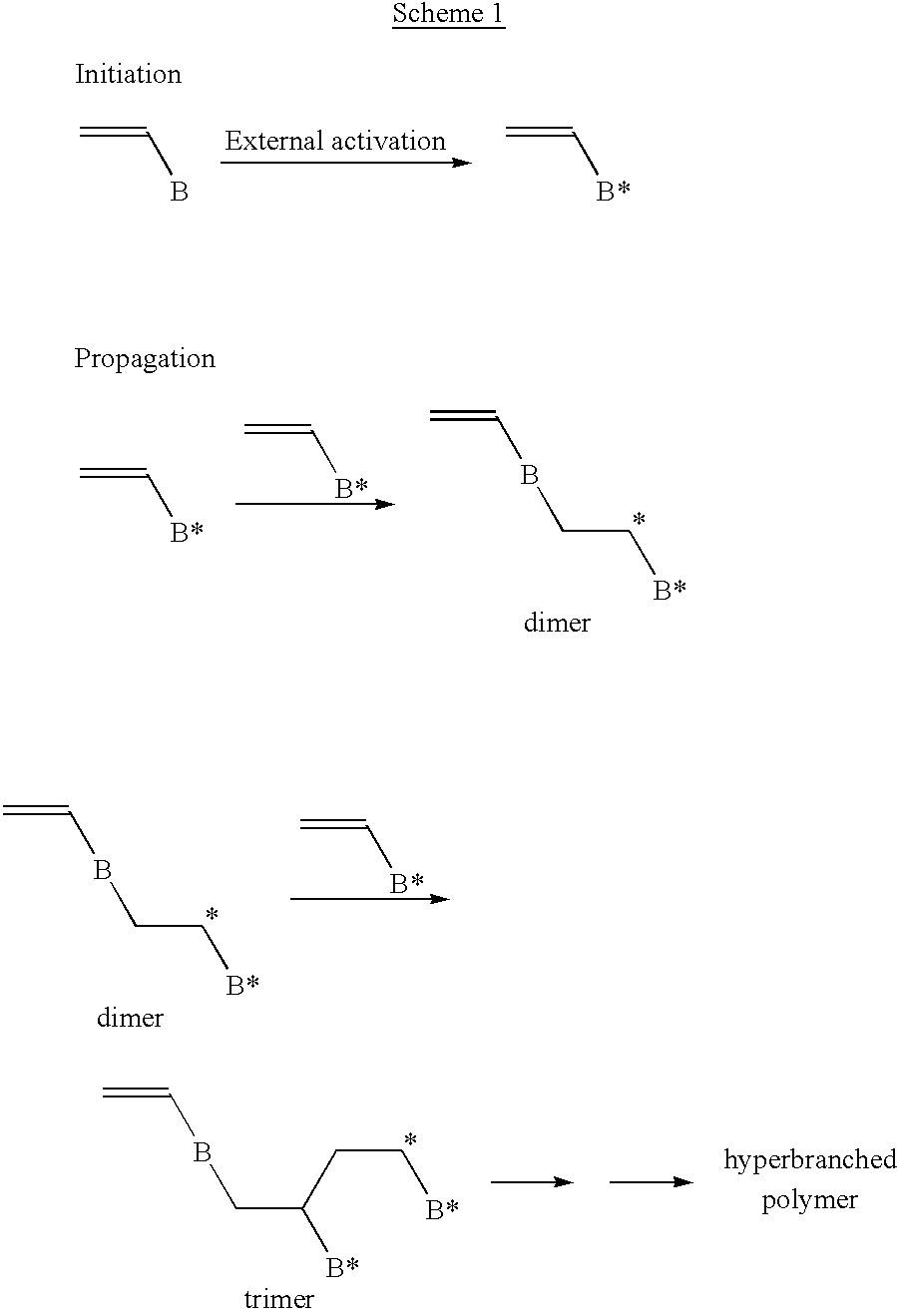

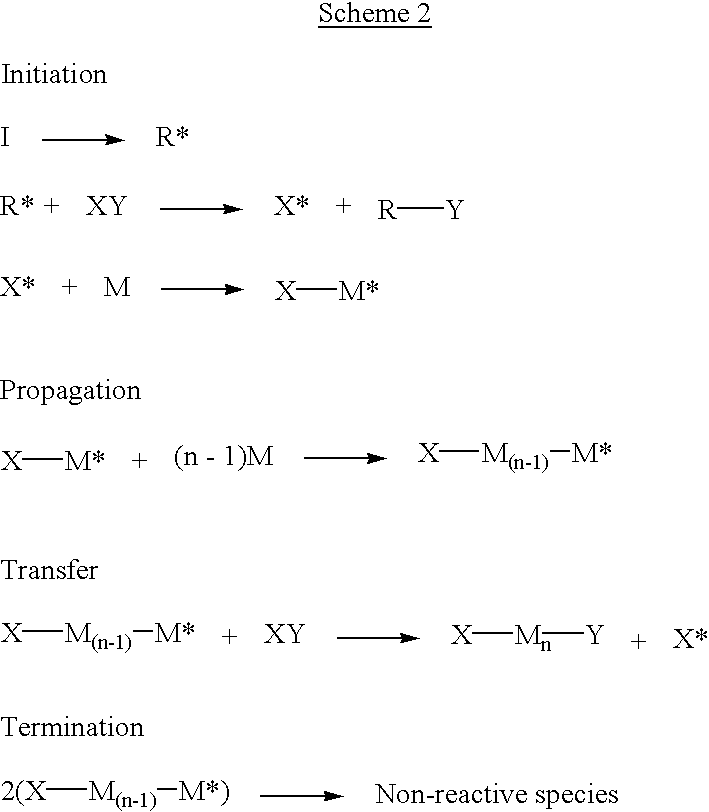

Method used

Image

Examples

example 1

[0084] Homopolymerzation of Allyl Trichloroacetate

[0085] The following reagents were first added into an air-free flask equipped with a water condenser along with a stir bar:

1 allyl trichloroacetate 2.5 grams benzoyl peroxide 0.0476 grams chlorobenzene 1 ml

[0086] The solution was then purged with pure nitrogen for 15 minutes. The polymerization was conducted at 100.degree. C. for 18 hours. Polymer was recovered by precipitation from methanol. The conversion was 56% (.sup.1H NMR) and molecular weight and molecular weight distribution were 3680 and 1.28 (GPC based on polystyrene calibration), respectively. The % of branching units in polymer is ca. 56% by means of .sup.13C NMR.

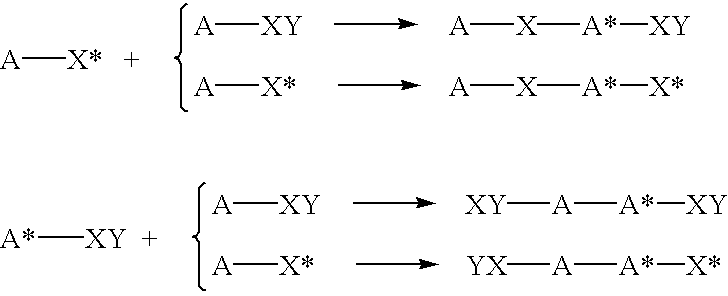

[0087] The following reaction scheme is an example of how radical telomerization of allyl trichloroacetate may yield hyperbranched polymer in accordance with Example 1.

[0088] Initiation With Radical Initiator BPO 2021

[0089] Termination: Combination of Two Radicals

example 2

[0090] Homopolymerzation of N-Allyl Trichloroacetamide

[0091] Polymerization was conducted under the same conditions as in example 1 except using allyl trichloroamide instead of allyl trichloroacetate. The conversion was 30% after 18 hours at 120.degree. C. (.sup.1H NMR) and molecular weight and molecular weight distribution were 862 and 1.37 (GPC based on polystyrene calibration), respectively.

example 3

[0092] Homopolymerzation of Allyl Tribromoacetate

[0093] The following reagents were first added into an air-free flask equipped with a water condenser along with a stir bar:

2 allyl trichloroacetate 2 grams benzoyl peroxide 0.024 grams

[0094] The solution was then purged with pure nitrogen for 15 minutes. The polymerization was conducted at 100.degree. C. for 8 hours. Polymer was recovered by precipitation from methanol. The conversion was 100% (.sup.1H NMR) and molecular weight and molecular weight distribution were 1240 and 2.13 (GPC based on polystyrene calibration), respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction rates | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com