Nitride semiconductor, method for manufacturing the same and nitride semiconductor device

a technology of nitride semiconductor and semiconductor device, which is applied in the direction of semiconductor lasers, lasers, solid-state devices, etc., can solve the problems of cracks and defects, large lattice distortion, and difficult to obtain laser structure without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

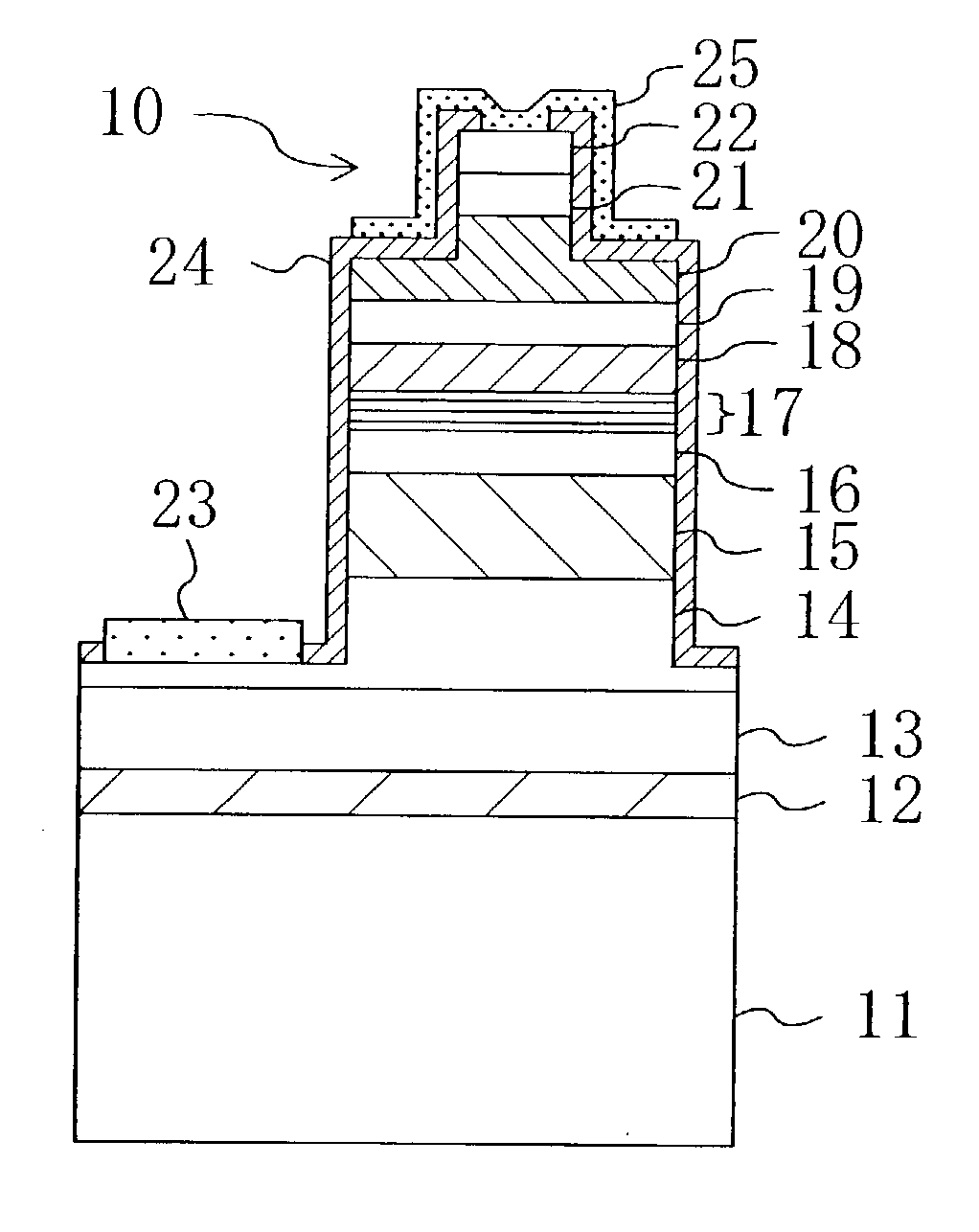

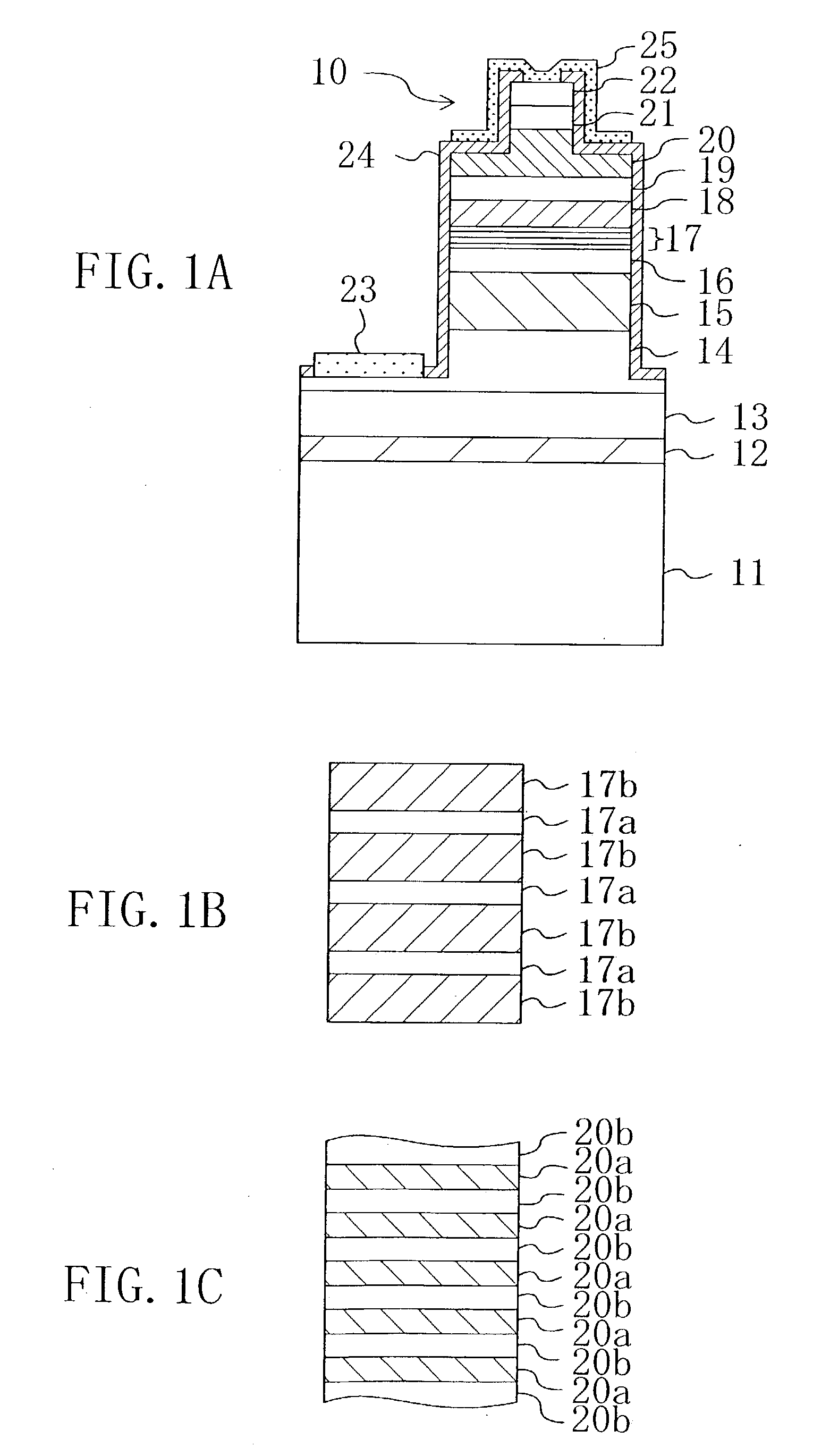

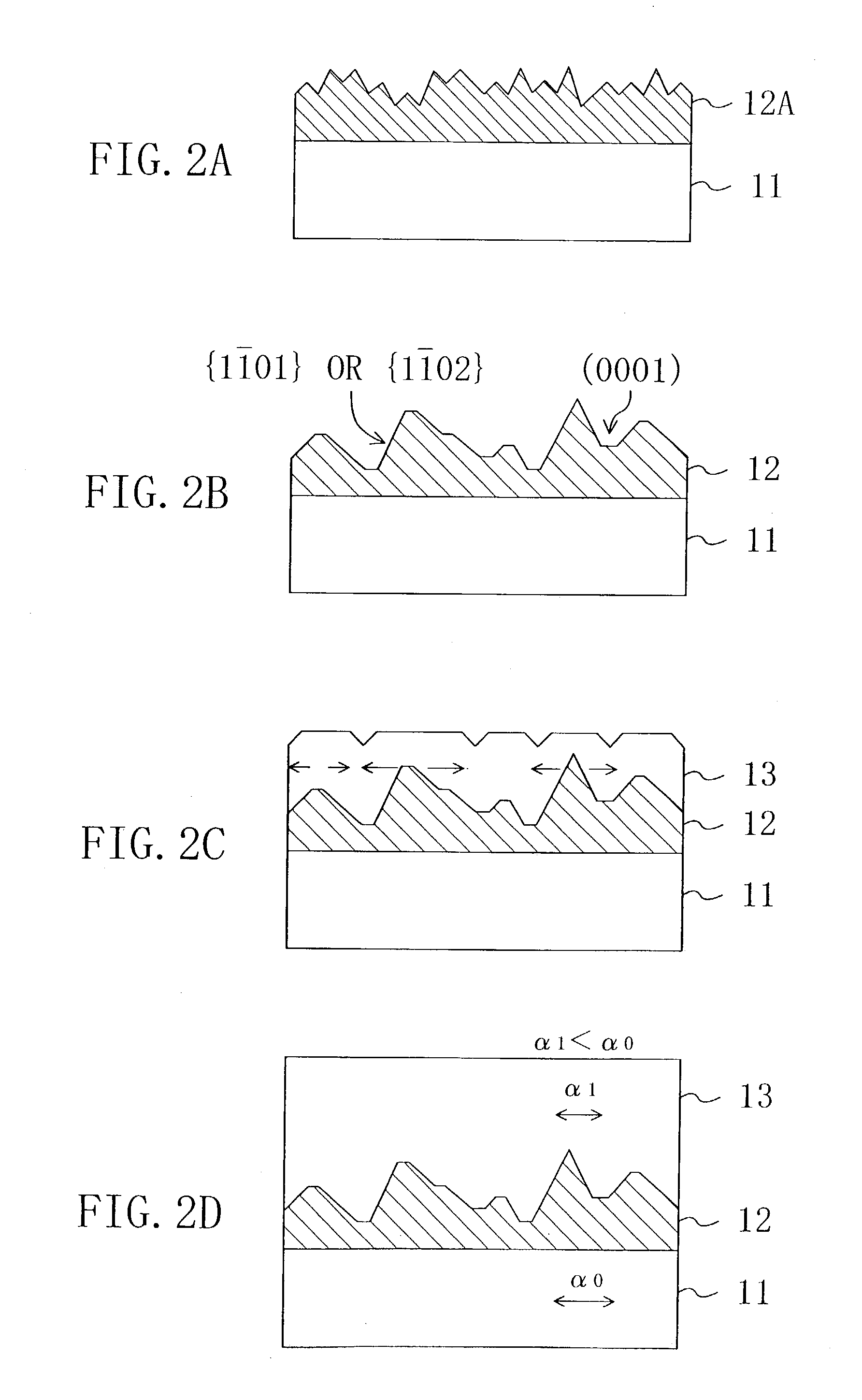

first embodiment

[0100] A modified example of the present invention will be described hereinafter with reference to the drawings.

[0101] FIG. 4 shows a cross-sectional structure of nitride semiconductor laser device relating to a modified example of the first embodiment of the present invention. Referring to FIG. 4, the same structural members as those of FIG. 1(a) are denoted by the same reference numerals and description thereof will be omitted.

[0102] As shown in FIG. 4, in accordance with this modified example, instead of the substrate 11 made of undoped gallium nitride (GaN), an n-type conductive substrate 31 made of n-type gallium nitride into which an n-type dopant such as silicon (Si), germanium (Ge) or oxygen (O) is added is used.

[0103] In accordance with a method for manufacturing the semiconductor laser device of this modified example, an n-type facet-forming layer 32 made of n-type AlGaInN with Si or the like being added thereto is formed on the n-type substrate 31. On the formed n-type fa...

second embodiment

[0108] Second Embodiment

[0109] A second embodiment of the present invention will be described hereinafter with reference to the drawings.

[0110] FIG. 5 shows a cross-sectional structure of nitride semiconductor laser device relating to a second embodiment of the present invention. Referring to FIG. 5, the same structural members as those of FIG. 1(a) are denoted by the same reference numerals and descriptions thereof will be omitted.

[0111] As shown in FIG. 5, in accordance with a semiconductor laser device relating to the second embodiment, a selective growth layer 41 that is made of AlGaInN and has a plurality of recessed portions 41a extending in a stripe manner is formed by growth on the facet-forming layer 12 made of AlGaInN. A mask film 42 made of, e.g., silicon nitride (SiN.sub.x) is formed on a bottom surface and a wall surface of each recessed portion 41a of the selective growth layer 41.

[0112] A lateral growth layer 43 made of GaN is formed by growth on a surface of the sele...

first modified example

[0121] First Modified Example of Second Embodiment

[0122] A first modified example of the second embodiment of the present invention will be described hereinafter with reference to the drawings.

[0123] FIG. 7 shows a cross-sectional structure of nitride semiconductor laser device relating to the first modified example of the second embodiment of the present invention. Referring to FIG. 7, the same structural members as those of FIG. 5 are denoted by the same reference numerals and descriptions thereof will be omitted.

[0124] As shown in FIG. 7, in accordance with the first modified example, instead of the substrate 11 made of undoped GaN, a conductive n-type substrate 31 made of n-type gallium nitride into which an n-type dopant such as Si, Ge or O is added is used.

[0125] In accordance with a method for manufacturing the semiconductor laser device of the first modified example, on the n-type substrate 31, an n-type facet-forming layer 32 made of n-type AlGaInN with Si or the like being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oscillation wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com