Method for the manufacturing of an aluminium-magnesium-lithium alloy product

a technology of magnesium-lithium alloy and manufacturing method, which is applied in the field of manufacturing method of aluminium-magnesium-lithium alloy product, can solve the problems of anisotropy of mechanical properties and fracture toughness, insufficient homogenisation effect, and insufficient homogenisation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

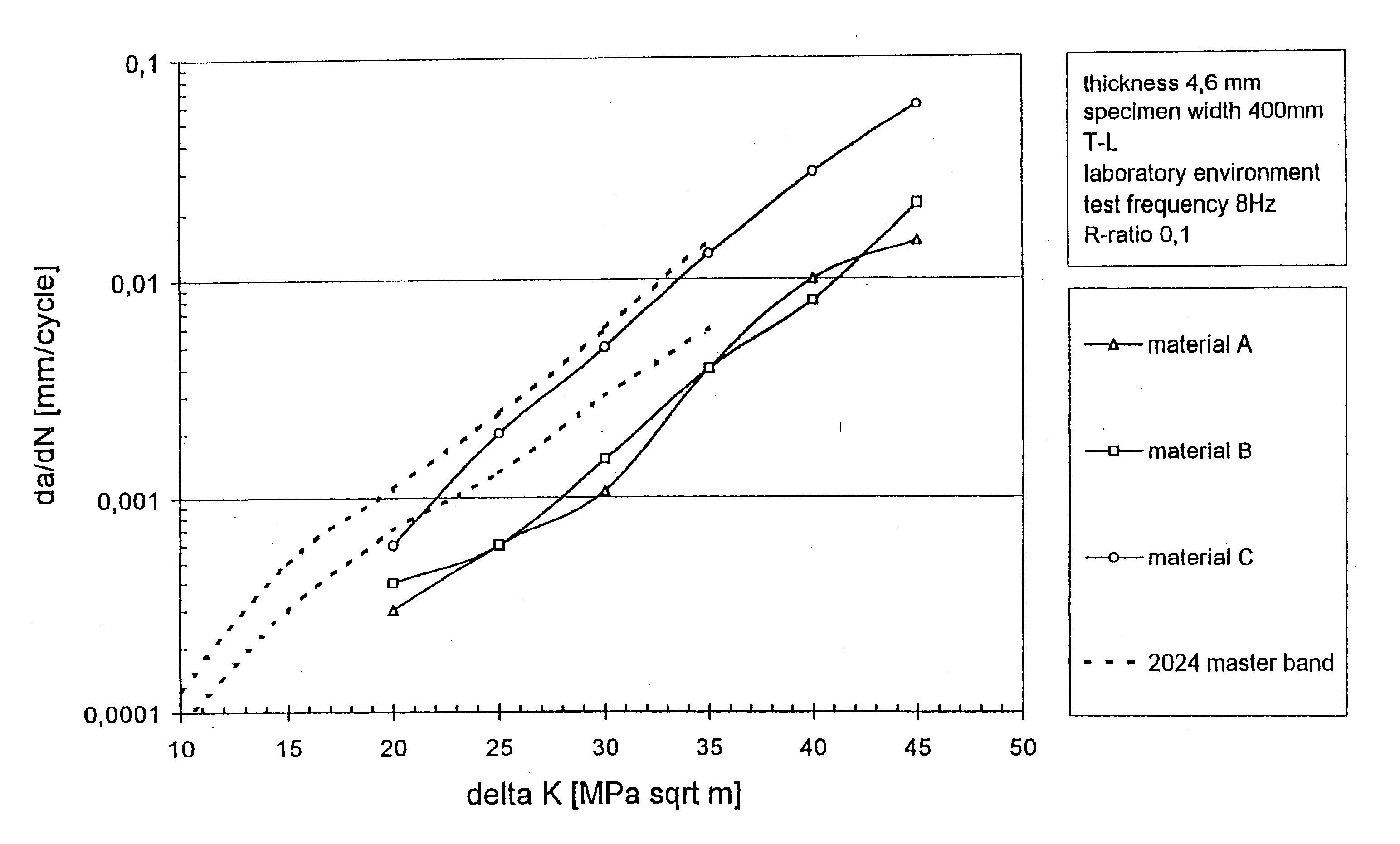

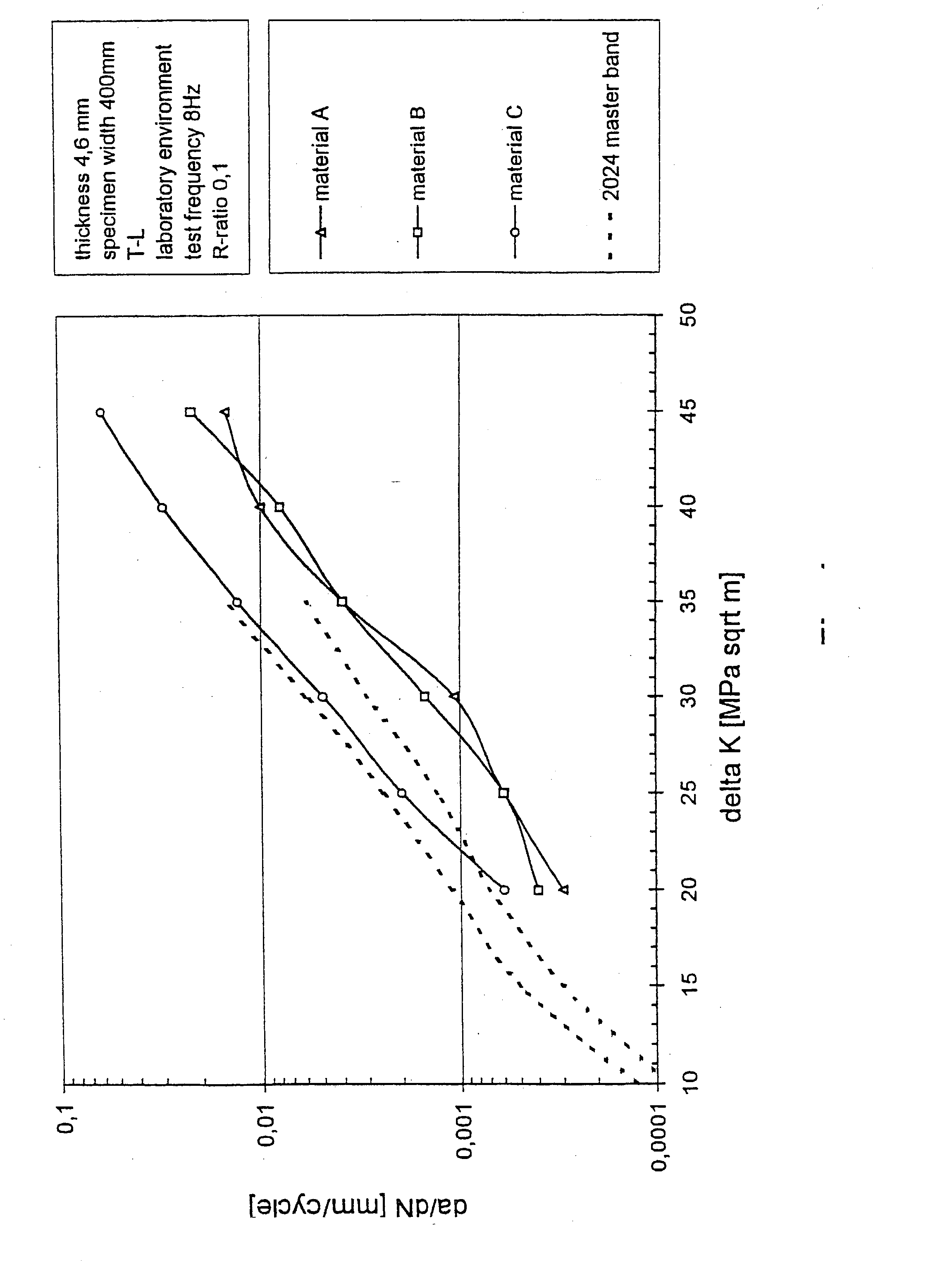

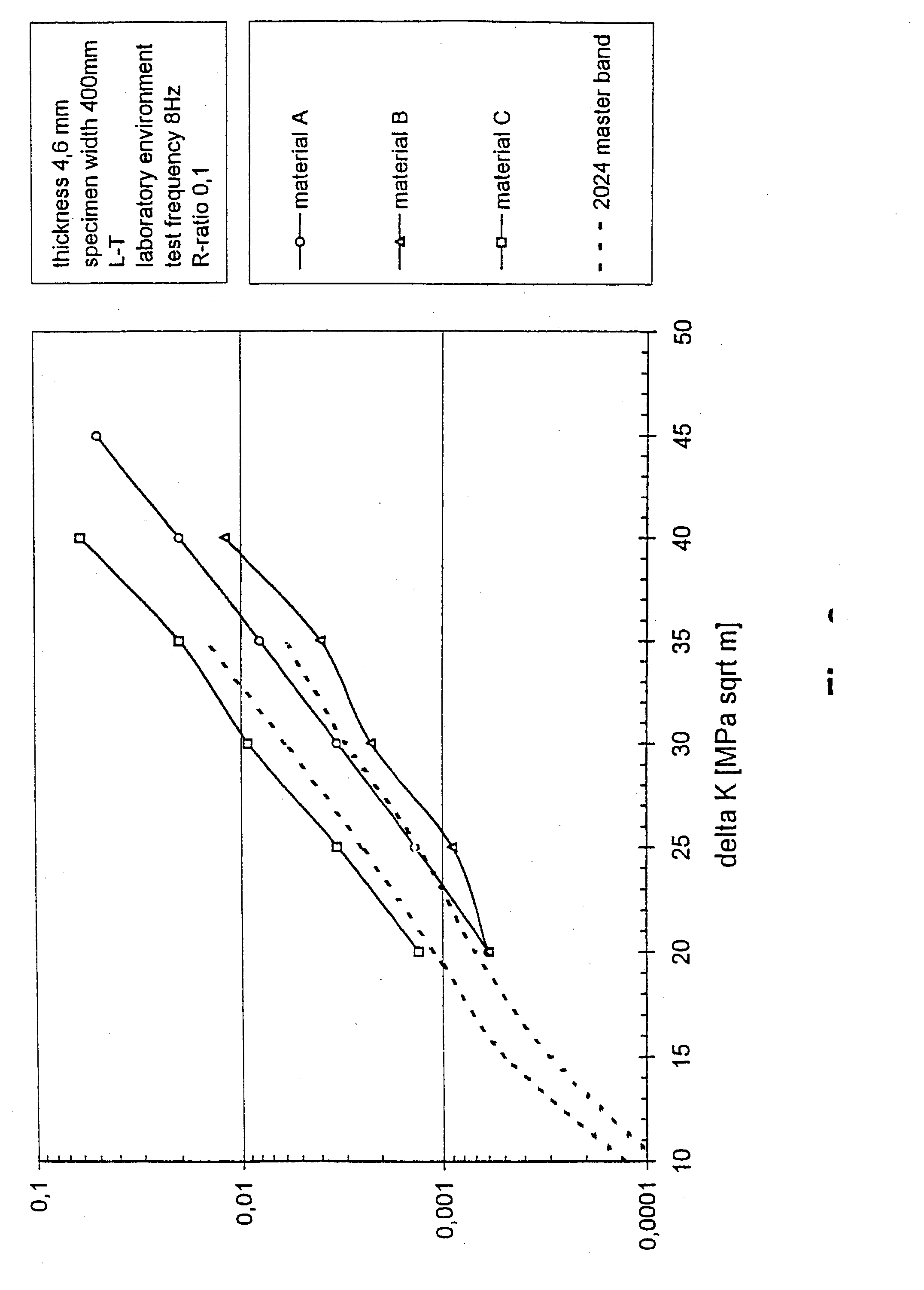

example 1

[0065] Three ingots have been produced on an industrial scale, of which there are two manufactured in accordance with the invention and one is manufactured for comparison. Three ingots A, B and C (compositions are listed in Table 1) having dimensions 350.times.1450.times.2500 mm have been preheated to 395.degree. C. for about 8 hours, and then hot rolled in their width direction to an intermediate thickness of 153 mm followed again by preheating to 395.degree. C. for about 8 hours, and hot rolled in their length direction to an intermediate thickness of 9 mm. Following hot rolling the hot rolled intermediate products are heat treated by holding the product for 100 minutes at 395.degree. C. followed by air cooling. In the next step material from ingot A is cold rolled in width direction in accordance with the invention to an intermediate thickness of 7.6 mm, while material from ingot B is being cold rolled in its length direction to the same intermediate thickness. Subsequently ingot...

example 2

[0076] In a similar way as in Example 1 three ingots (ingots D, E and F) have been produced on an industrial scale, of which there is one manufactured in accordance with the invention and two are manufactured for comparison. The chemical composition for all three ingots was the same and is listed in Table 6, and had starting dimensions of 350.times.1450.times.2500 mm. The processing route showed similarity with those of Example 1 and are summarised in Table 7. Two different temperatures for the solution heat treatment after cold rolling have been applied, viz. 530.degree. C. and 515.degree. C.

[0077] Following ageing the sheets have been tested for their mechanical properties as function of the direction, and for which the results are listed in Table 8 as function of solution heat treatment temperature; all results are an average over three specimens tested. For the tensile testing the specimens had dimensions of::1.sub.o50 mm, b.sub.o=12.5 mm, and d.sub.o4.6 mm.

[0078] From the resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com