Oriented polyolefin processing

a polyolefin and processing technology, applied in the direction of separation processes, ornamental textile articles, borehole/well accessories, etc., can solve the problems of low processing line start up cost and high shrinkage factor of processed films, and achieve the effects of improving processability, fewer web breaks and higher line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

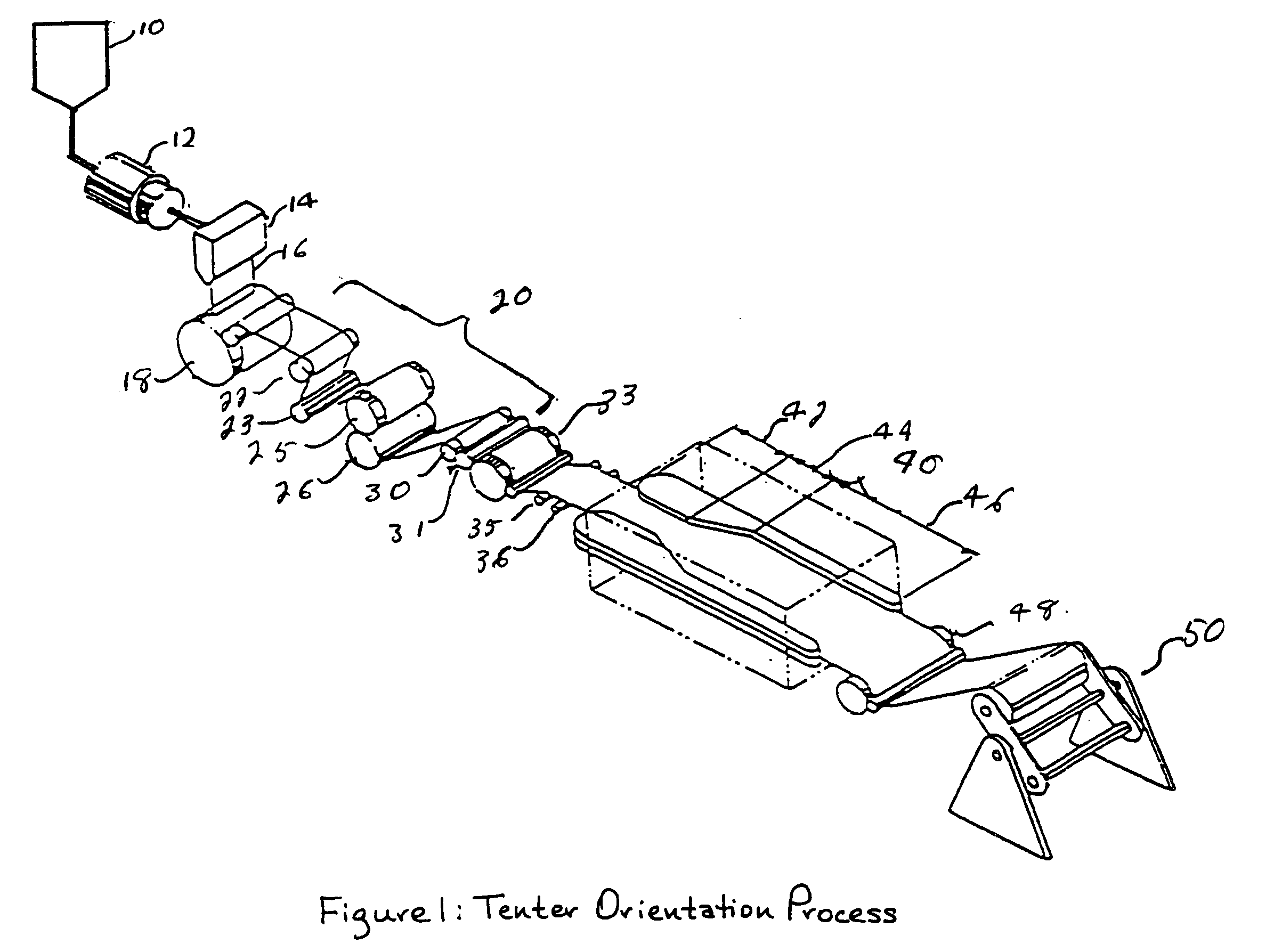

[0043] Several compositions with varying amounts of primarily isotactic polypropylene (referred to simply hereinafter as isotactic polypropylene or "iPP"), blended with a hydrocarbon resin, were processed through a biaxially oriented polypropylene film making process using a tenter frame system while measuring their processing properties. The hydrocarbon resin was melt blended with the polymer in a screw extruder.

[0044] The trial was conducted in a sixty inch continuous pilot tenter line capable of 76.2 meters per minute output. Biaxial orientation of flat films was carried out in two sequential steps. The casted sheet chilled on a rotating cold steel roll was firm stretched longitudinally (in the machine direction or "MD") in the tangential gap between sets of rolls rotating at different speeds. Subsequently, the film was stretched transversely (in the transverse direction or "TD") in a tenter frame in which the edges of the film were gripped by a series of clips and diverged in TD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com