Rotary gas dispersion device for treating a liquid metal bath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

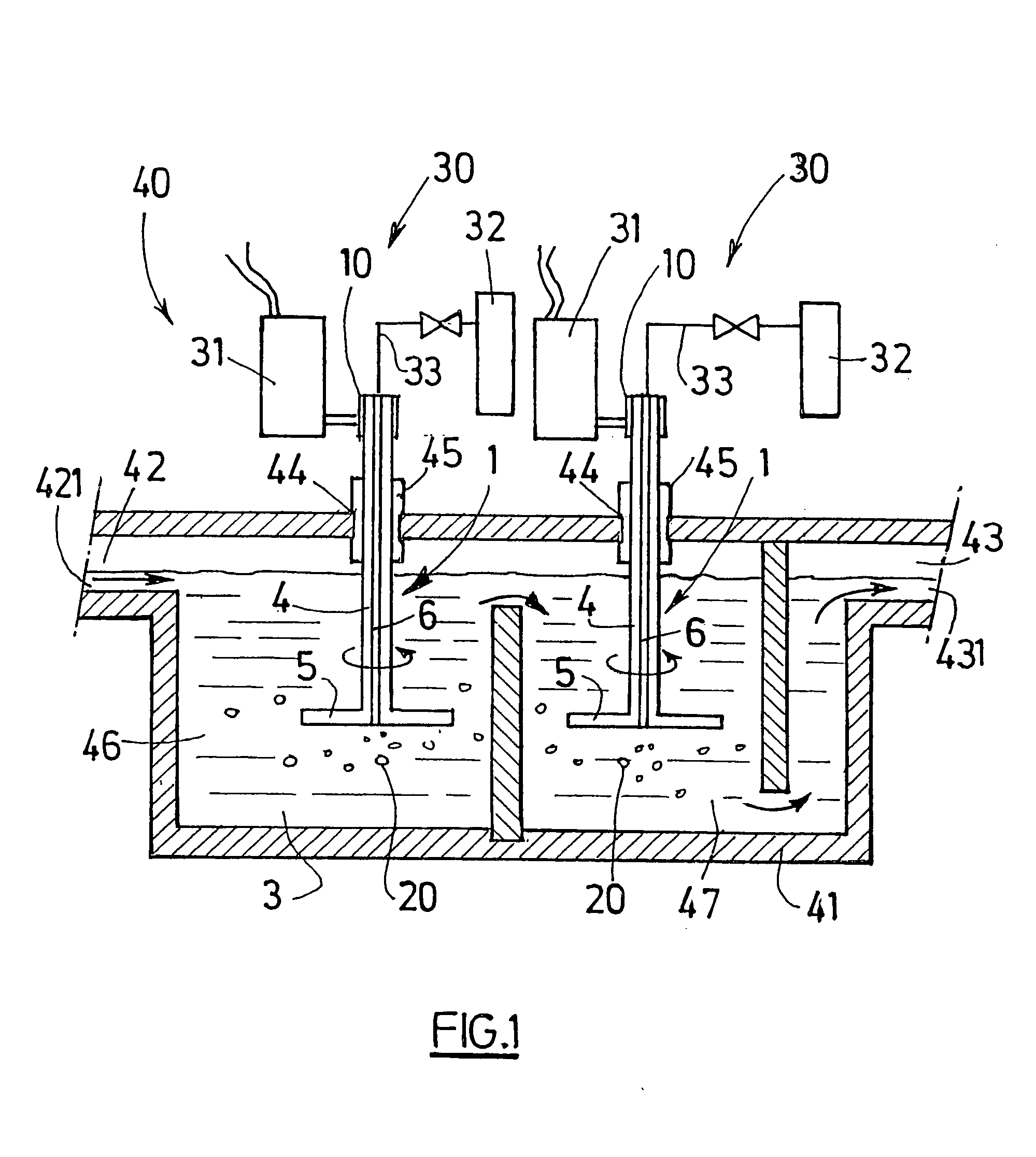

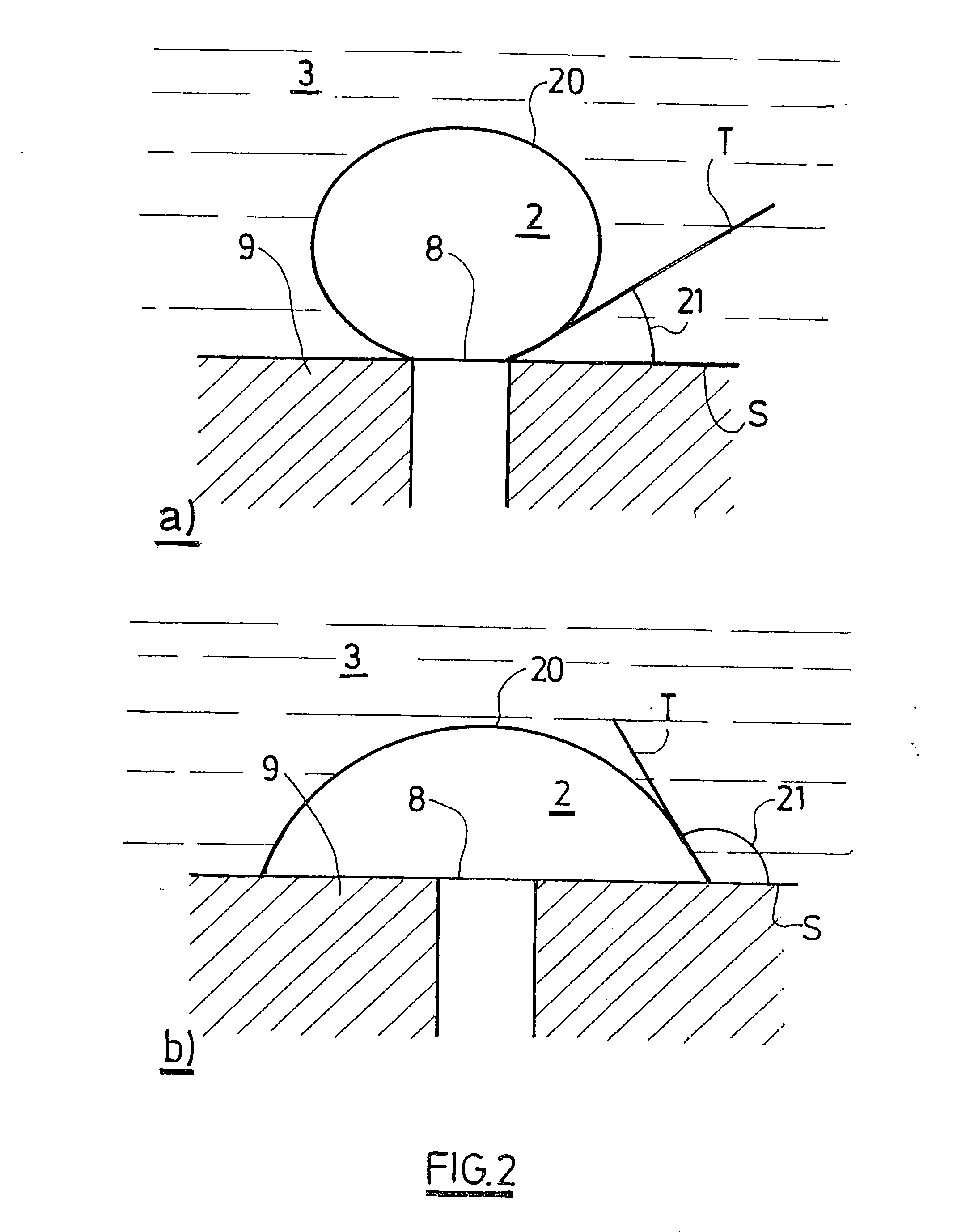

[0050] Tests were carried out in a small-sized experimental vat. The size of the bubbles formed was observed and determined by means of an X-ray camera. The method consists in using X-rays to irradiate the liquid metal bath 3, into which the bubbles 20 are emitted, in viewing said bubbles after recovering the image by means of a camera, and in measuring them after calibration of the acquisition chain.

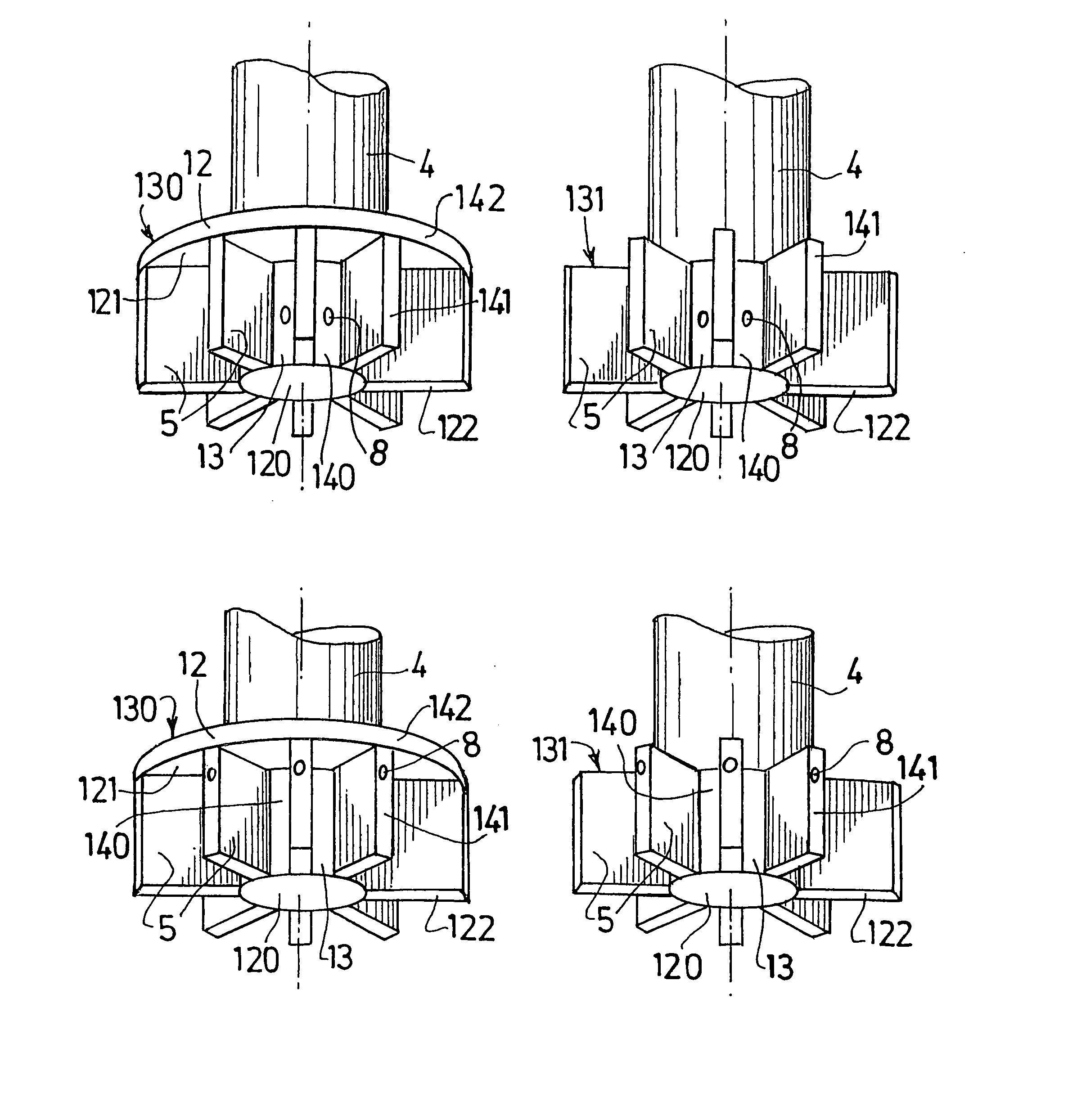

[0051] The tests were carried out with rotary injectors comparable to those illustrated in FIG. 3. In one case representative of the prior art, the blades and emitting means were made of graphite; in another case representative of the invention, they were made of titanium. In both cases, the orifices measured 1 mm in diameter.

[0052] In these tests, the applicant observed that, on the one hand, with the prior art injectors the bubbles had an average diameter of the order of 15 mm, a portion of the treatment gas was able to rise along the rotor and injector shaft and 20% of the injected g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wettability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap