Methods and apparatus for particle formation

a particle and apparatus technology, applied in the field of methods and apparatus for particle formation, can solve the problems of reduced product yield, problems such as problems, and processes such as seds that are not suitable for all types of target substances, and achieve the effect of high degree of control over product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1a

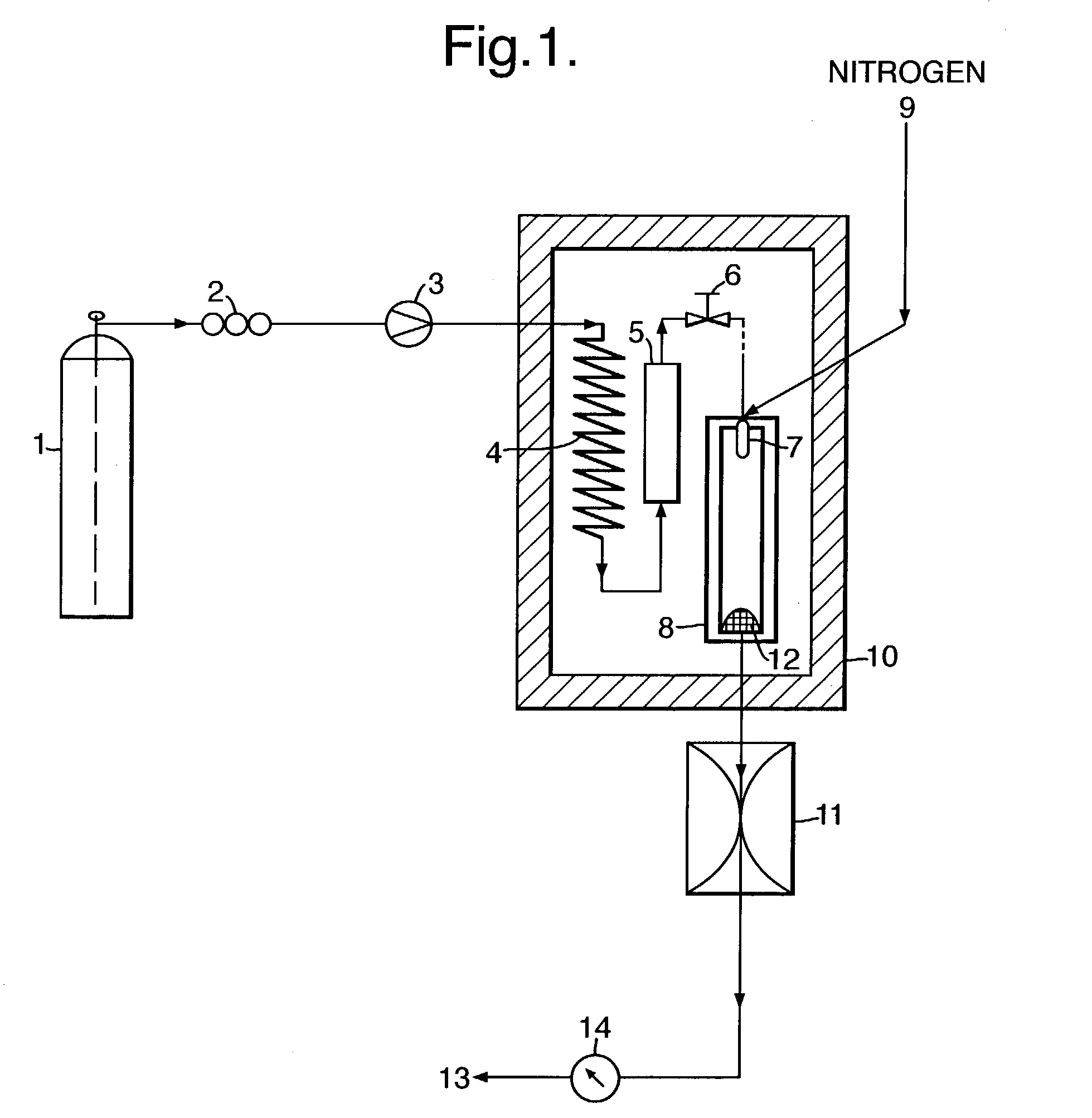

[0095] 1 g of ibuprofen was mixed with glass beads (200-300 micron, acid washed (Sigma, UK)) and introduced into a 10 ml Keystone vessel (the sample vessel 5) to form a uniform bed. The bed was sandwiched between two filters (average pore size 2 microns) to eliminate the risk of physical entrainment of drug particles in the carbon dioxide flow. The sample vessel was provided with a pressure regulator independent of that of the particle formation vessel 8.

[0096] The fluids were introduced into the particle formation vessel using a two-passage coaxial nozzle of the preferred type described above, having a 0.1 mm diameter outlet. The nozzle ensured thorough mixing of the fluids at their point of contact, ie, at their point of entry into the vessel. The conditions in the vessel were such that particle formation occurred simultaneously, or substantially so, on the fluids meeting and entering the vessel.

[0097] 1 ml / min of carbon dioxide (measured at the pump head) was pumped into the samp...

example 1b

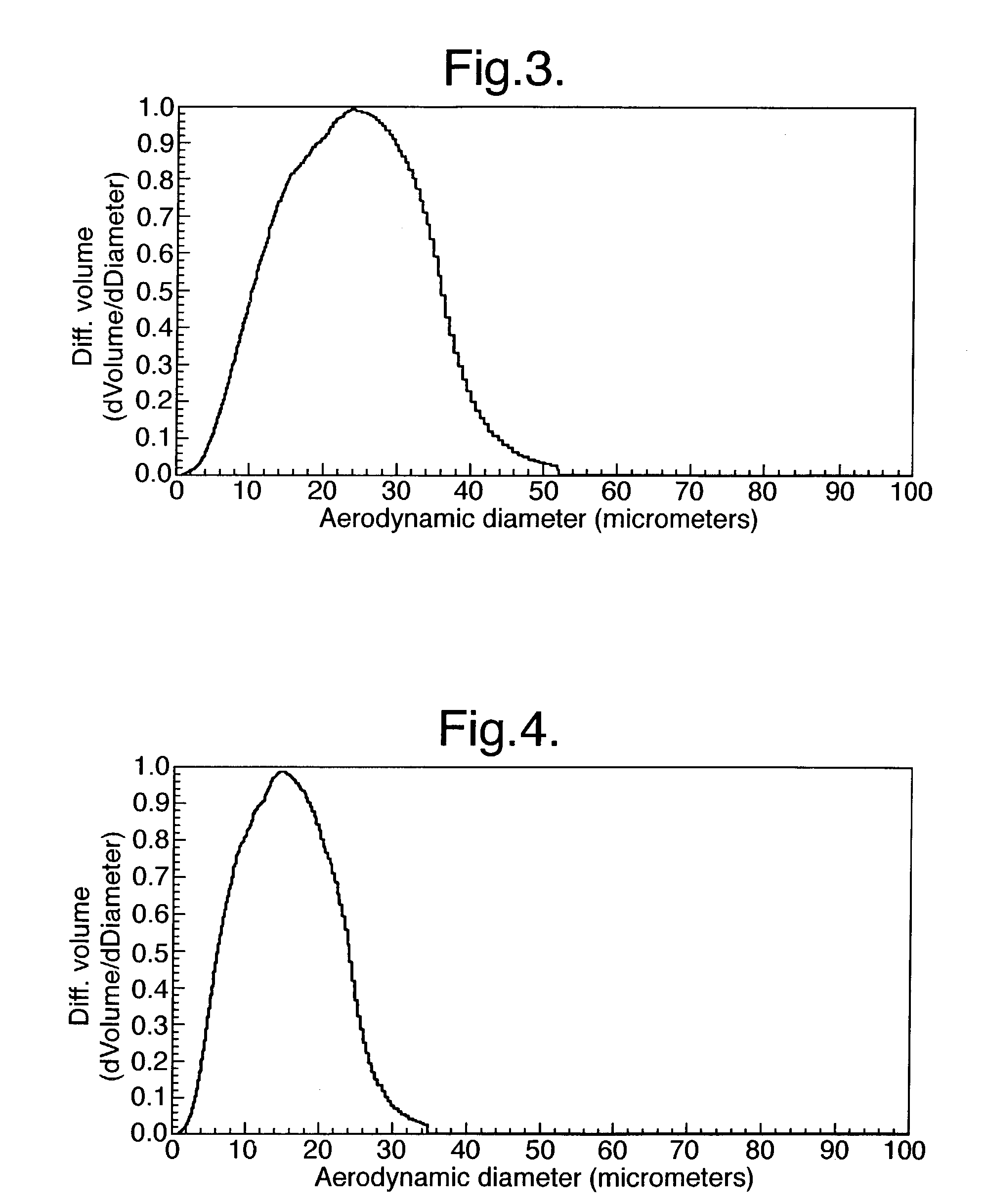

[0101] Example 1a was repeated, but with the carbon dioxide flow rate increased from 1 to 4 ml / min (at the pump head). All other operating conditions remained the same.

[0102] The product was a fine fluffy white powder. Analysis using the Aerosizer / Aerodisperser system yielded the particle size distribution curve shown in FIG. 4 and summarised in Table 2, The mean particle diameter, by volume, was about 14 micron.

2 TABLE 2 % UNDER SIZE % UNDER SIZE 5% 5.920 55% 16.18 10% 7.411 60% 17.07 15% 8.631 65% 17.99 20% 9.720 70% 18.94 25% 10.75 75% 19.95 30% 11.72 80% 21.05 35% 12.66 85% 22.25 40% 13.56 90% 23.67 45% 14.43 95% 25.84 50% 15.30 Mean size: 14.12 Standard deviation: 1.586

example 1c

[0103] Again Example 1a was repeated, but this time with a carbon dioxide flow rate of 8 ml / min (at the pump head). The product was again a fine fluffy white powder, which when analysed (see FIG. 5 and Table 3) showed a mean particle diameter, by volume, of about 8 micron.

3 TABLE 3 % UNDER SIZE % UNDER SIZE 5% 3.762 55% 9.186 10% 4.462 60% 9.849 15% 5.018 65% 10.55 20% 5.518 70% 11.28 25% 5.999 75% 12.06 30% 6.479 80% 12.92 35% 6.966 85% 13.88 40% 7.471 90% 14.96 45% 8.004 95% 16.35 50% 8.572 Mean size: 8.333 Standard deviation: 1.589

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com