Coining holographic images into contoured surfaces on hard temper metal products

a technology of hard temper metal products and microengraving, which is applied in the direction of metal extrusion, extrusion dies, manufacturing tools, etc., can solve the problems of fragile master holograms produced in photoresist materials, easy to fade and peel off, and relatively soft surface of holograms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

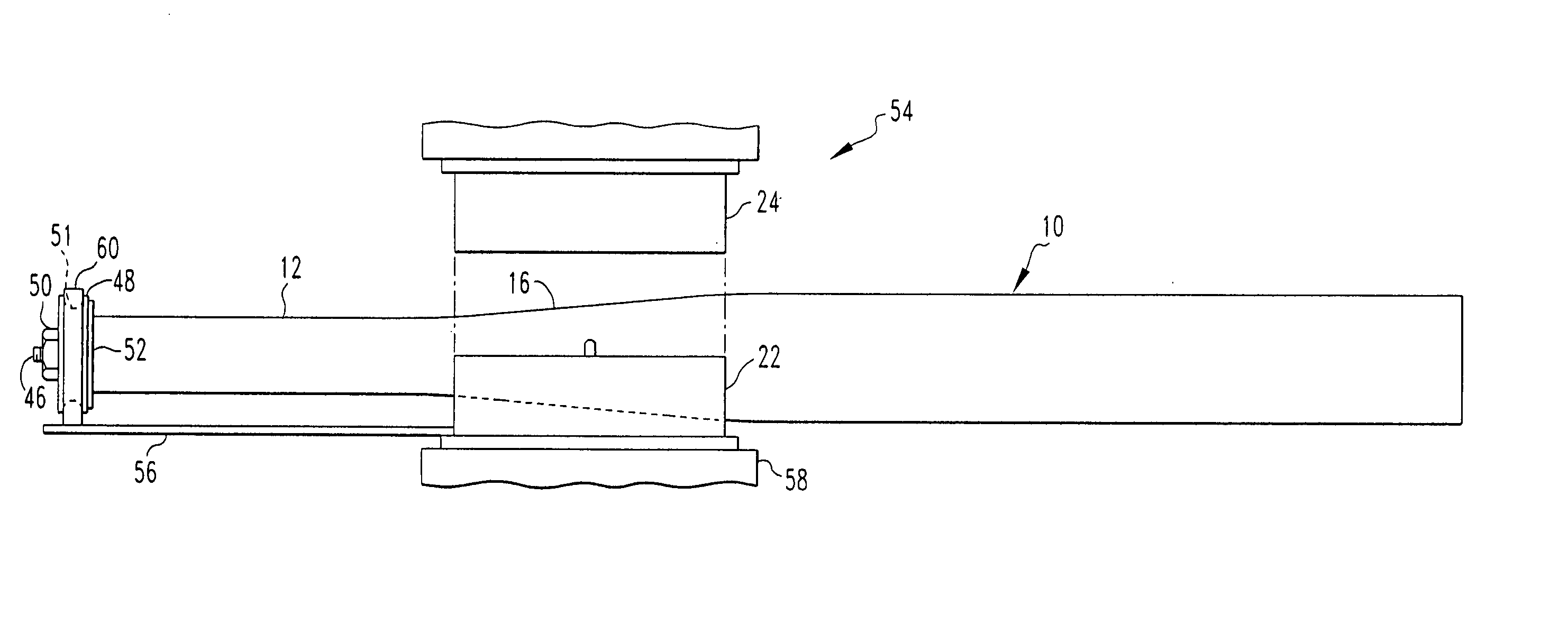

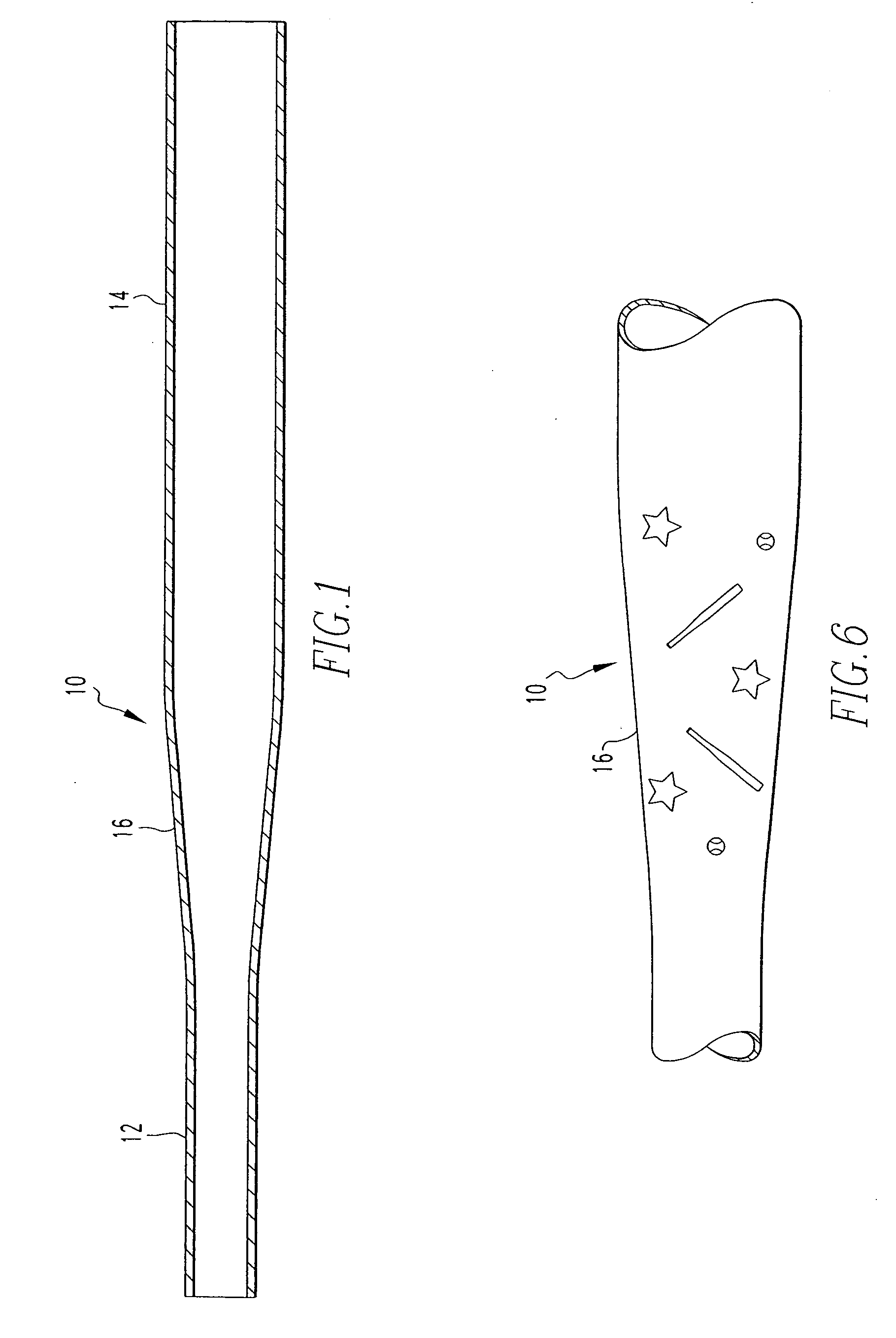

[0061] FIG. 5 shows one example of an aluminum ball bat that had been decorated by the method of this invention having a hologram comprising pictures of bats, balls and stars coined in or embossed on its surface. The light which reflects off the hologram produces varying looks or images as the bat is moved in the light. The hologram image has been transferred to the tapered portion only of the bat. However, this invention may also be used to transfer holographic images to the barrel or handle portions of the bat.

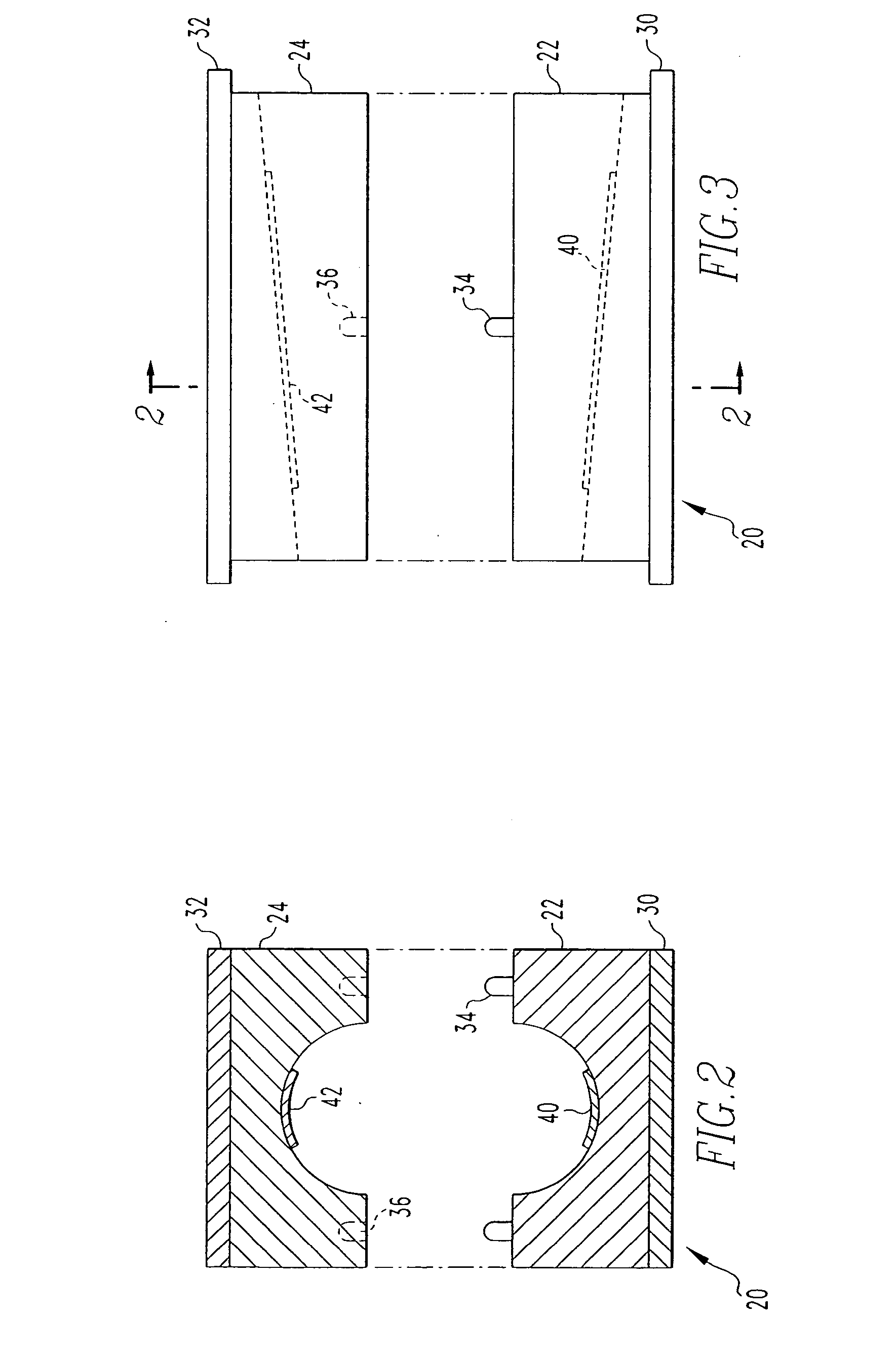

[0062] The shims in the method of FIGS. 3 and 4 have negative holographic images on them and press a positive image in the exterior surface of bats. The image in the photoresist material preferably comprises pits (dot matrix), the image on the mother shim comprises peaks (dot matrix), the images on the sister shims comprise pits, and the images in the surface of the bats comprise peaks. It is important to the method of FIGS. 3 and 4 that the shims have a surface hardness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com