Method for treating semiconductor processing components and components formed thereby

a technology for semiconductor processing components and components, applied in the direction of silicon carbide, transportation and packaging, carbide, etc., can solve the problems of insufficiently addressing certain contamination issues, and the technology appears limited to restoring pre-machined purity levels to the componen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

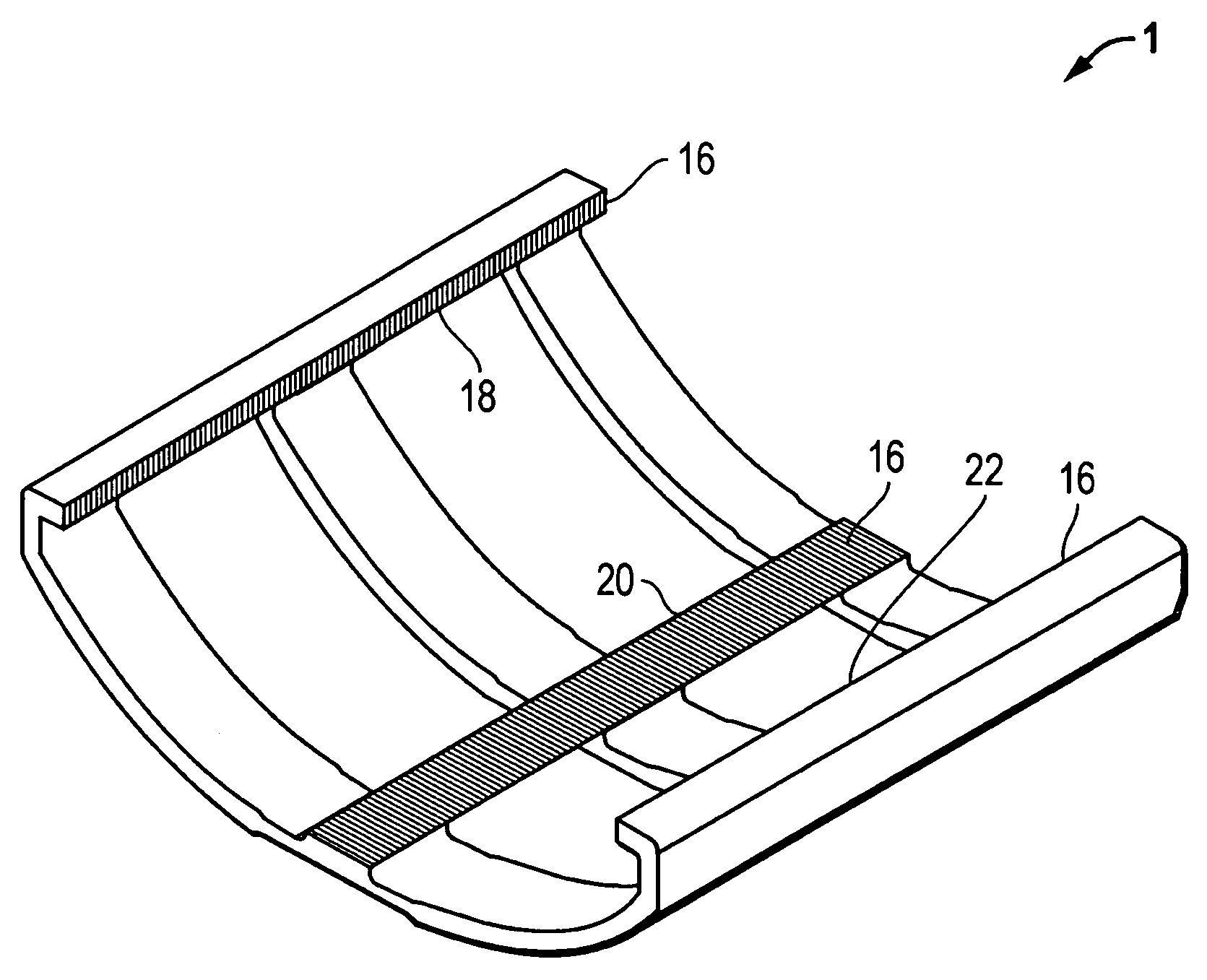

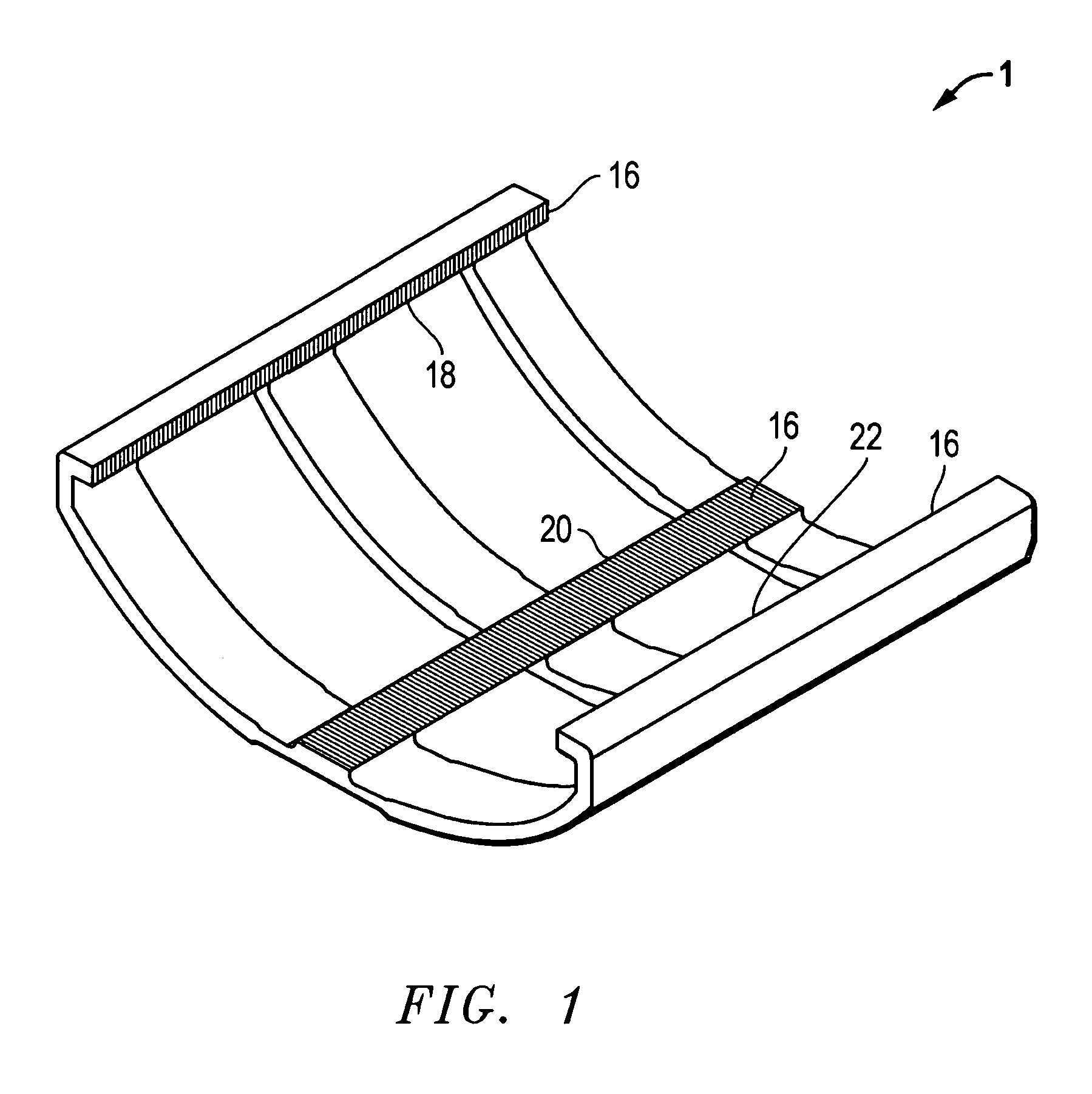

[0018] According to aspects of the present invention, a semiconductor processing component, and a method for treating a semiconductor processing component are provided. The semiconductor processing component generally is formed at least partially of SiC, including an outer surface portion that has a controlled impurity content. The outer surface portion is typically formed by chemical vapor deposition (CVD), and has an outer purity that is not greater than ten times a bulk purity. The outer surface portion may be defined as an identifiable SiC layer formed by CVD, or an outer thickness of a SiC component formed principally by CVD, as in the case of free-standing CVD-SiC components, described in more detail below.

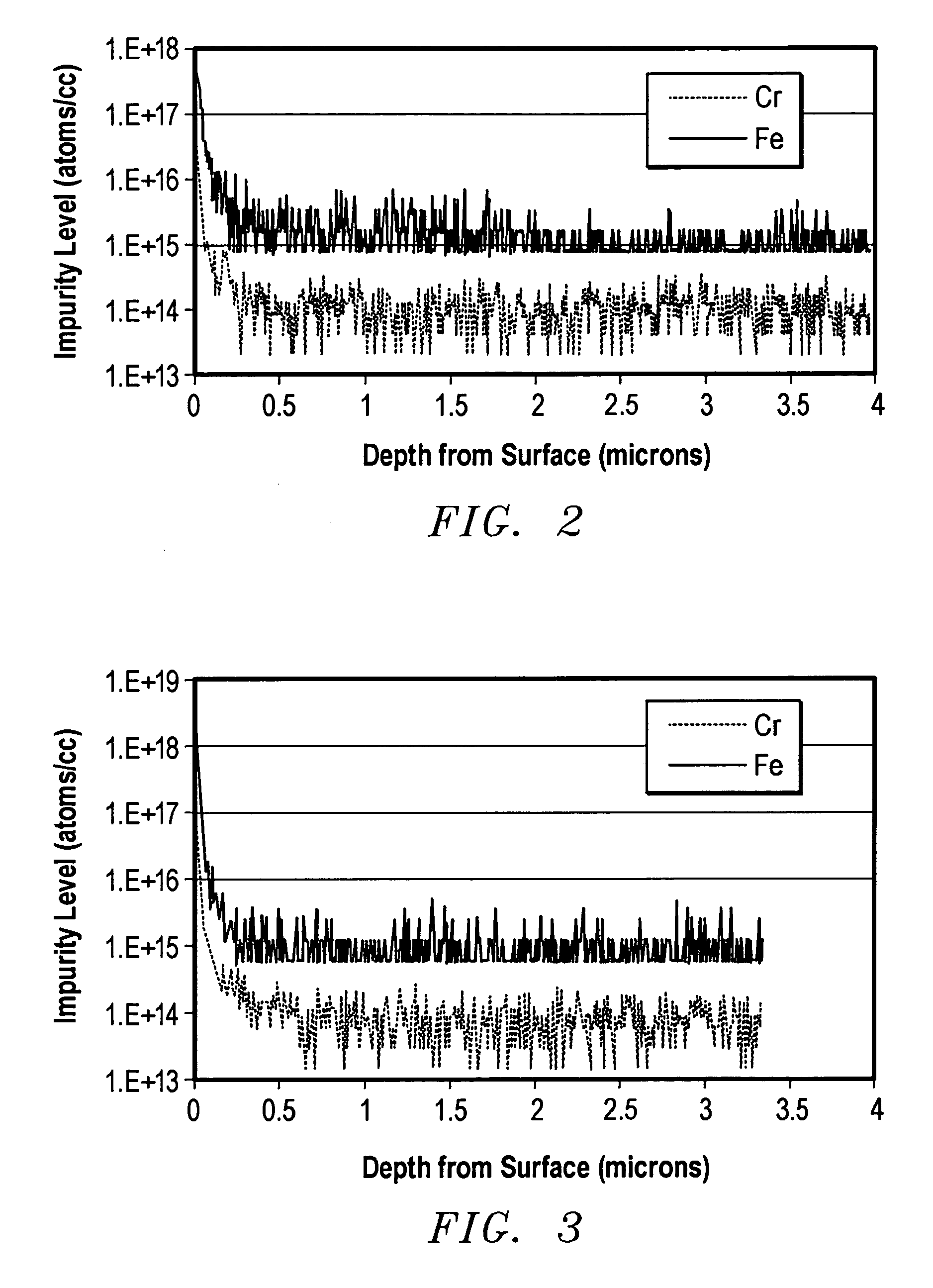

[0019] According to one aspect, the present inventors have recognized that as-deposited CVD-SiC has a spike in impurity levels at the outer surface thereof, typically within the first 0.5 .mu.m, such as within the first 0.25 .mu.m, or the first 0.10 .mu.m of the outer depth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com