Method and apparatus for processing a substrate with rinsing liquid

a substrate and rinsing liquid technology, applied in the field of substrate processing methods and substrate processing apparatuses, can solve the problems of large improvement space, large improvement space, and ineffective countermeasures, and achieve the prevention of rinsing-induced oxidation of the substrate surface, rapid increase of concentration of dissolved oxygen in the rinsing liquid, and large improvement space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

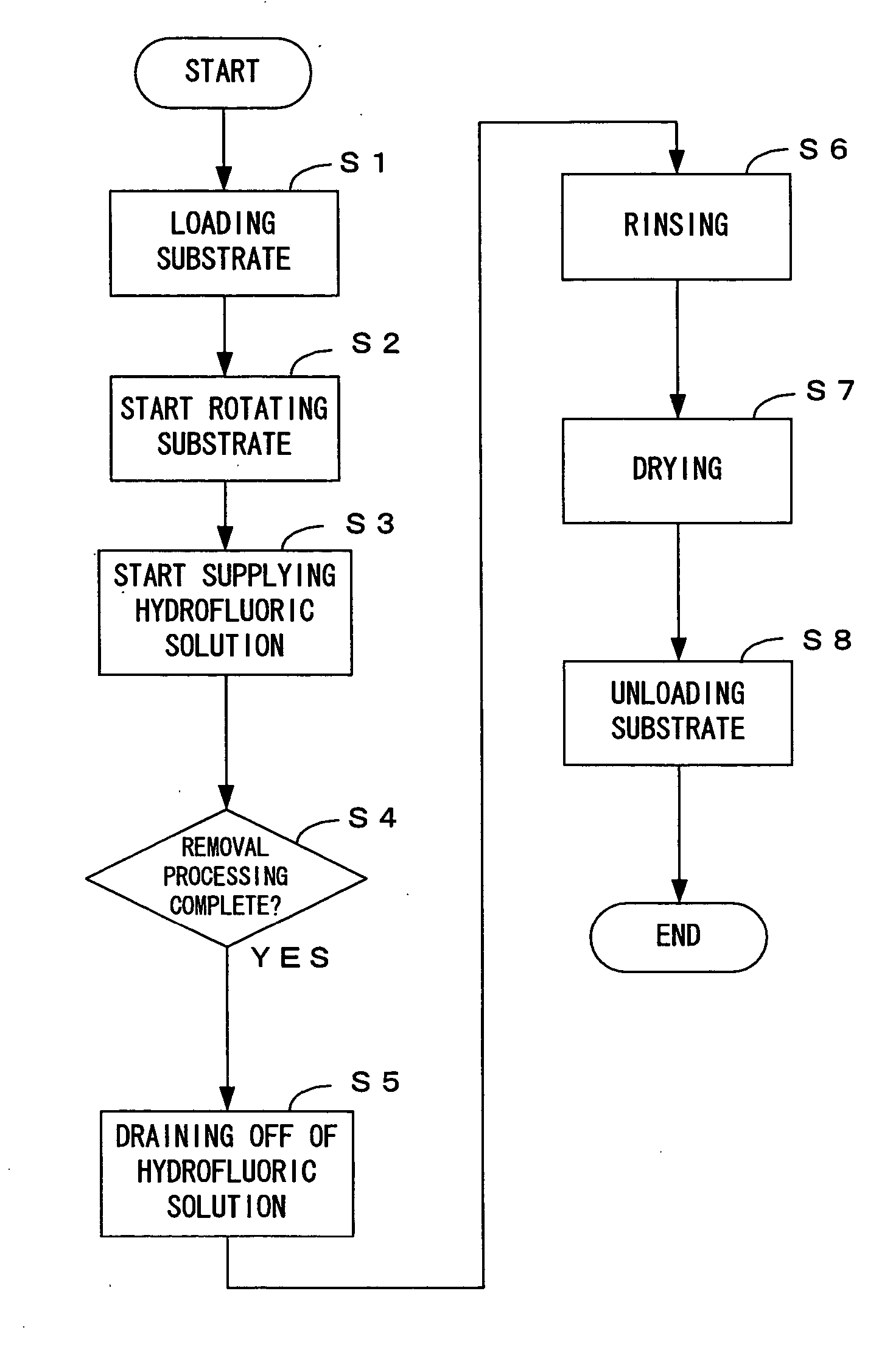

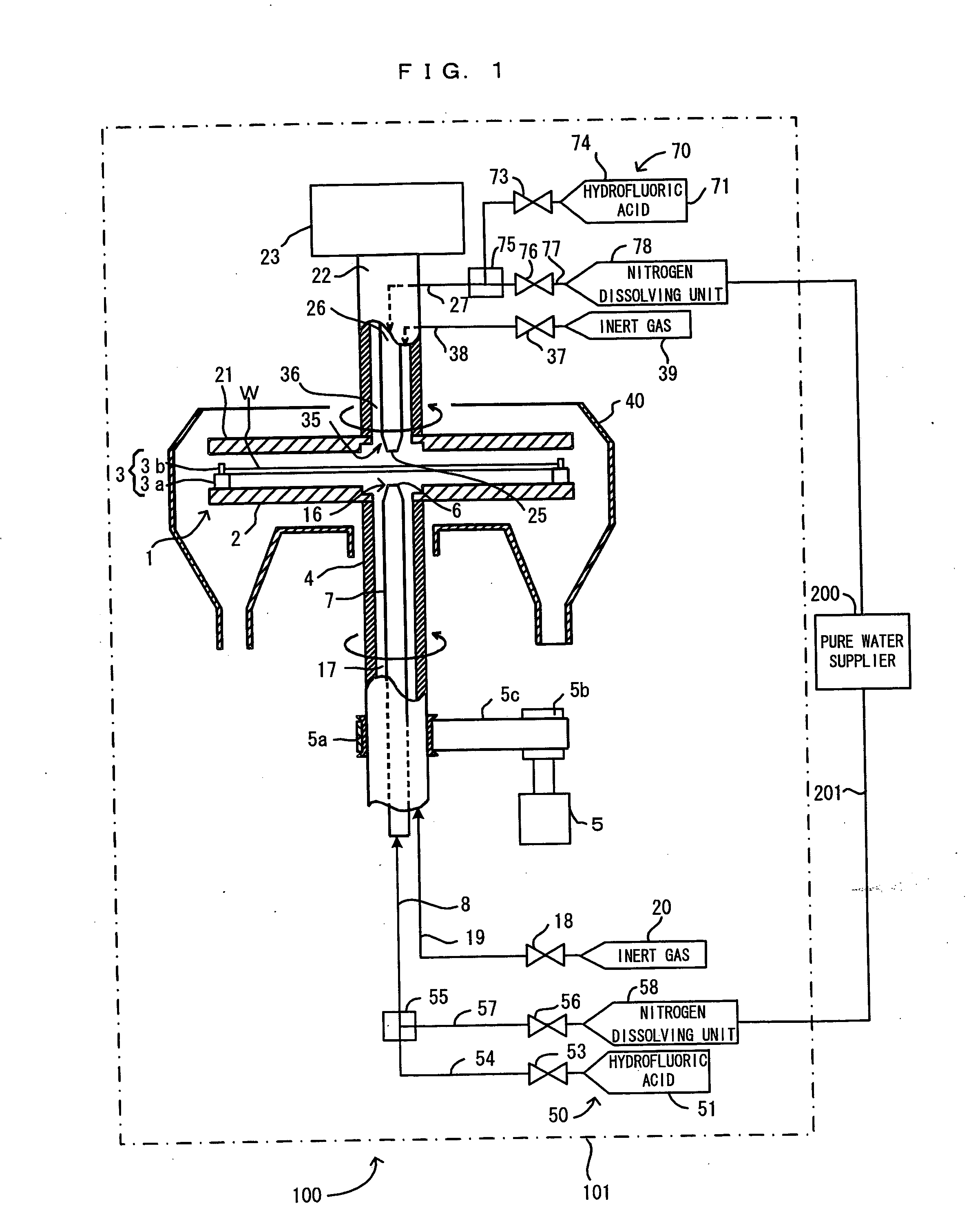

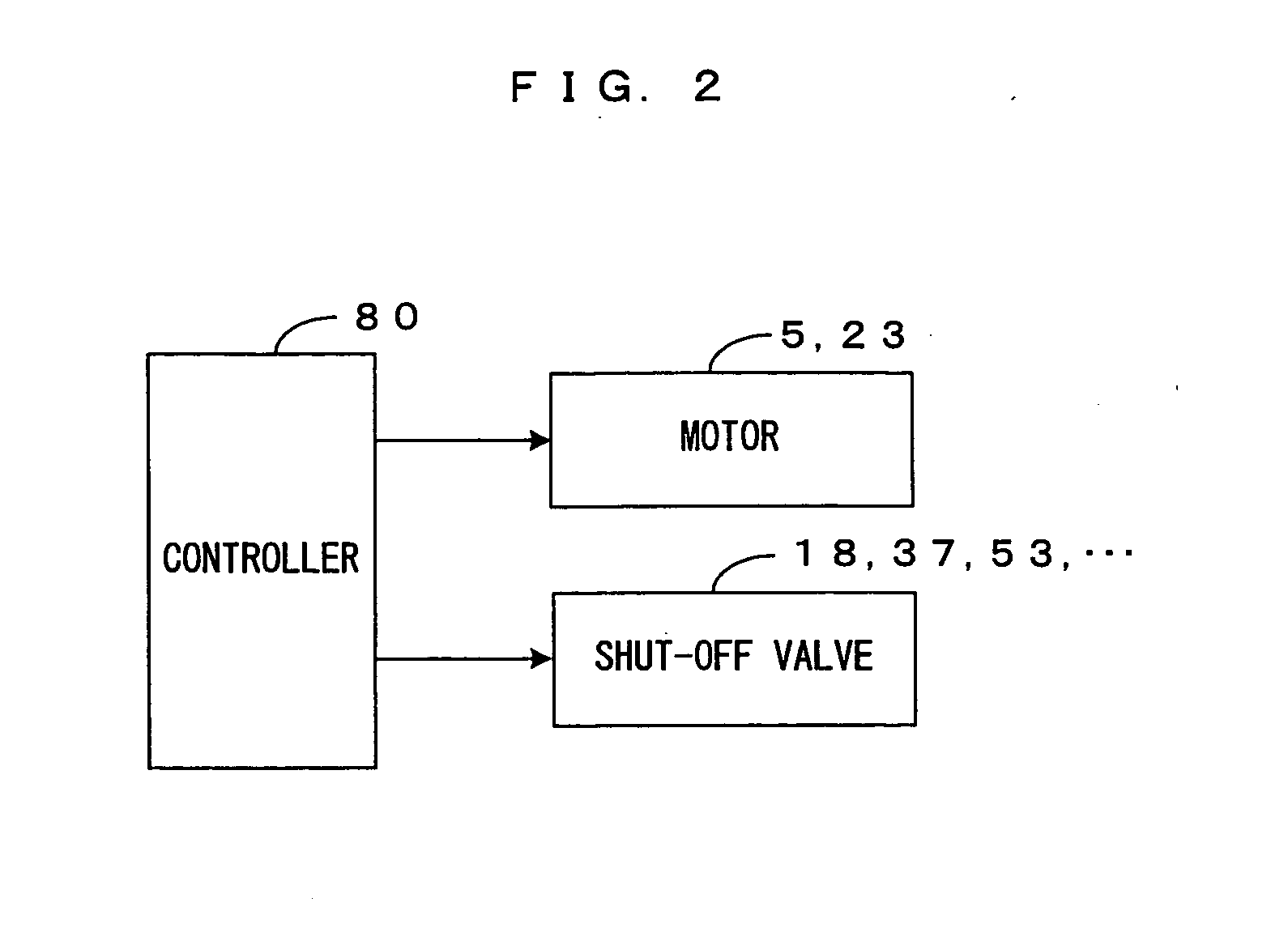

[0020]FIG. 1 is a cross sectional view which shows the structure of a substrate processing apparatus as a whole according to the present invention. FIG. 2 is a block diagram which shows the structure of control executed in the substrate processing apparatus of FIG. 1. Within this substrate processing apparatus 100, as shown in FIG. 1, a substrate W as it is held by a spin chuck 1 is subjected to film removal processing, rinsing and drying inside the same processing unit main section 101.

[0021] The spin chuck 1 comprises a disk-shaped base member 2, which also serves as a blocking member disposed on the back surface side of the substrate, and three or more holding members 3 which are formed on the top surface of the base member 2. Each one of the holding members 3 comprises a support part 3a, which receives and supports the substrate W from below at an outer peripheral portion of the substrate W, and a restriction part 3b which restricts the position of the outer edge of the substrat...

second embodiment

[0052] as well, since the deaeration units 59 and 79 are disposed together with the nitrogen dissolving units 58 and 78 within the processing unit main section 101, nitrogen is added after the deaeration of the pure water and the rinsing liquid is consequently produced, whereby the paths for the rinsing liquid until discharge at the nozzles 6 and 25 are shortened. Thus produced rinsing liquid is supplied to the substrate W quickly, and an increase of the concentration of dissolved oxygen in the rinsing liquid is more effectively suppressed.

[0053] With respect to the locations of the deaeration units 59 and 79, for a similar reason to that regarding the nitrogen dissolving units 58 and 78 in the first embodiment, it is desirable that the capacity of the rinsing liquid remaining in the rinsing liquid paths from the deaeration units 59 and 79 respectively to the outlets of the nozzles 6 and 25 is one liter or less. As ranges for suppressing an increase of the concentration of dissolve...

third embodiment

[0057] In contrast, the nitrogen dissolving unit 58 (78) is disposed outside the processing unit main section 101 according to the Hence, the nitrogen dissolving unit 58 (78) adds an abundant amount of nitrogen to the pure water, and an increase of the concentration of dissolved oxygen in the pure water arriving at the processing unit main section 101 is suppressed. While it is desirable that the nitrogen dissolving unit 58 (78) is disposed right behind the branching from the circulation path 200b where oxygen could be dissolved in the pure water in this regard, considering the duration of the effect of added nitrogen, it is equally desirable that the nitrogen dissolving unit 58 (78) is disposed such that the capacity of the rinsing liquid remaining in the rinsing liquid path from the nitrogen dissolving unit 58 (78) to the outlet of the nozzle 6 (25) will be 200 liters or less.

[0058] According to the third embodiment as well, as in the second embodiment, the deaeration unit 59 (79...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com