Method of fabricating semiconductor memory device and semiconductor memory device driver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A description will now be given of embodiments of the present invention with reference to the accompanying drawings.

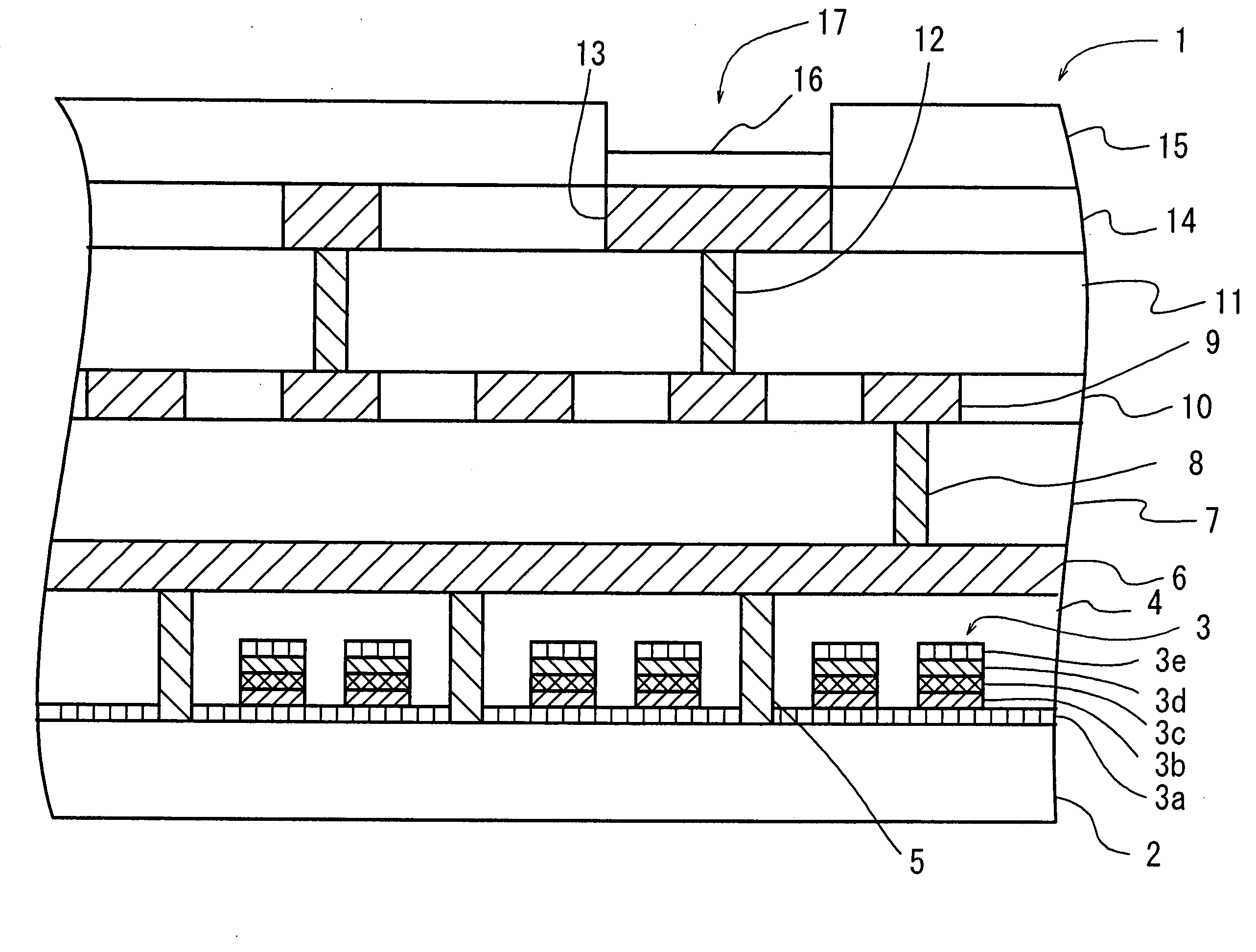

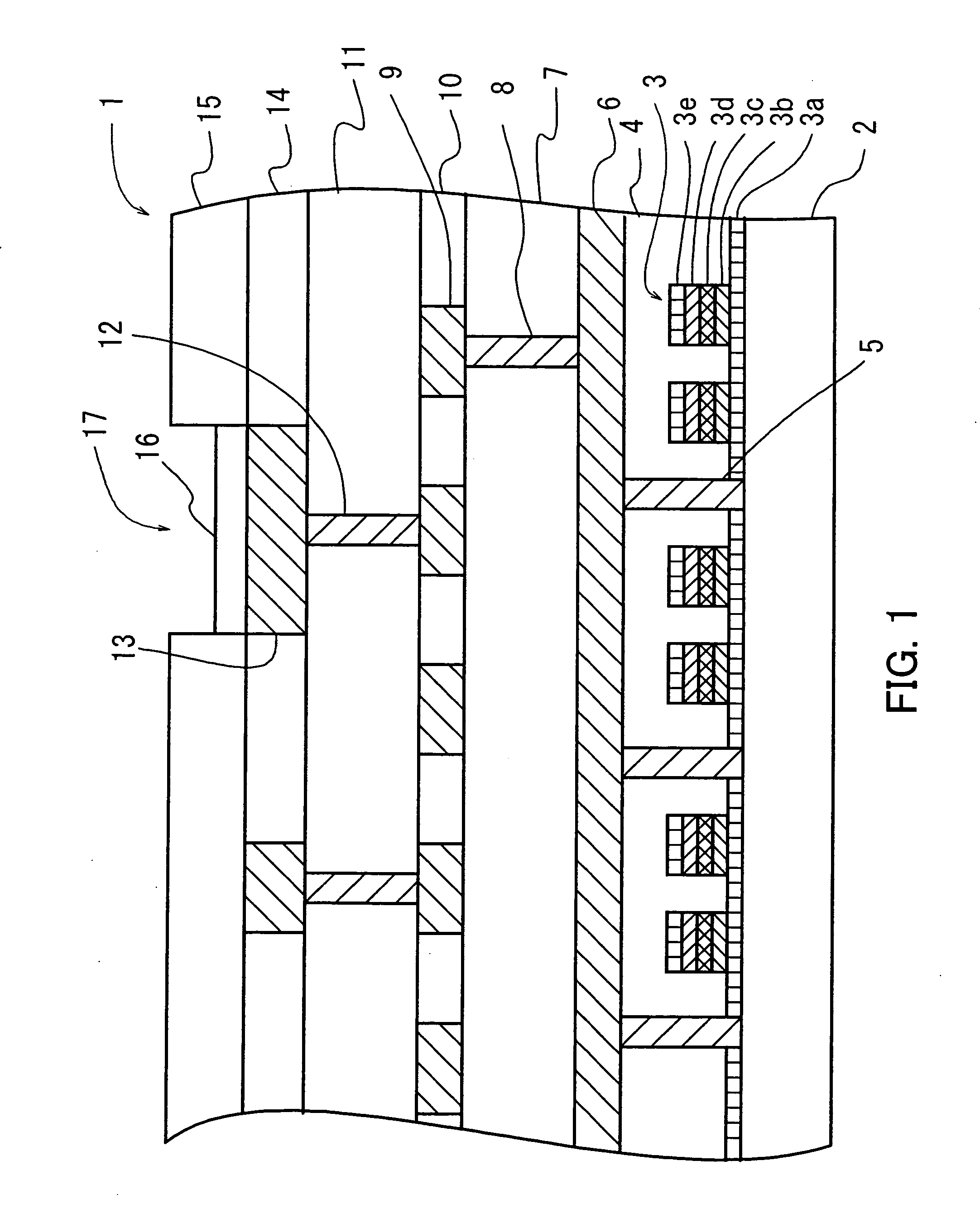

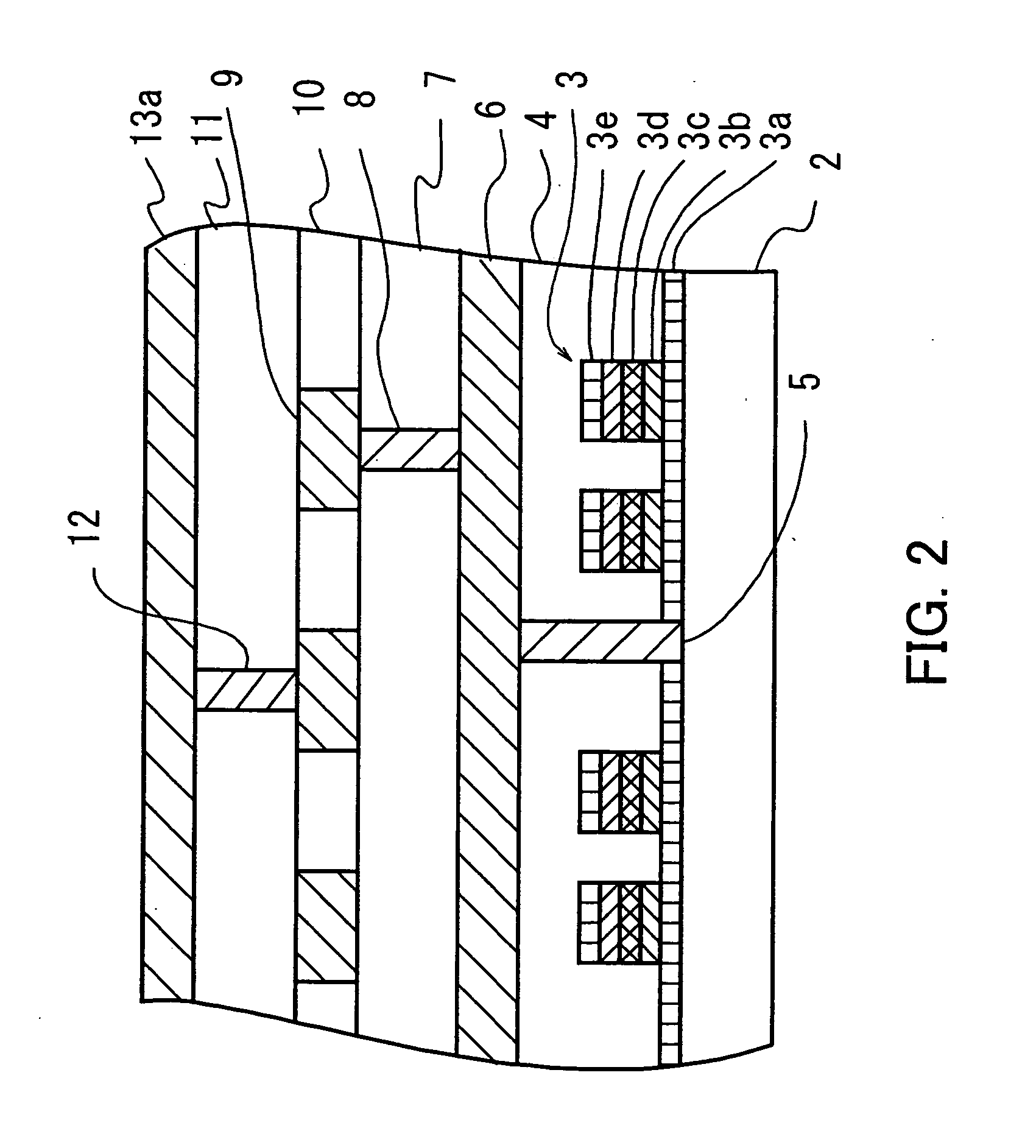

[0030]FIG. 1 shows a structure of the semiconductor memory device of the present invention. The semiconductor memory device that is assigned to a reference numeral of 1 in FIG. 1 has a structure of the flash memory.

[0031] The structure of the semiconductor memory device 1 is described. Gates 3 are formed on a silicon (Si) substrate 2, and a film 4 for flattening is formed so as to cover the gates 3. Via wirings 5 are formed for making connections between the silicon substrate 2 and a metal interconnection 6. An interlayer insulating film 7 is formed on the metal interconnection 6. A via wiring 8 is formed to electrically connect the metal interconnection 6 and a metal interconnection 9 located above the interconnection 6. A film 10 for flattening is formed on the interlayer insulating film 7 so as to cover the metal interconnection 9. Another interlayer insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com