Apparatus for producing hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

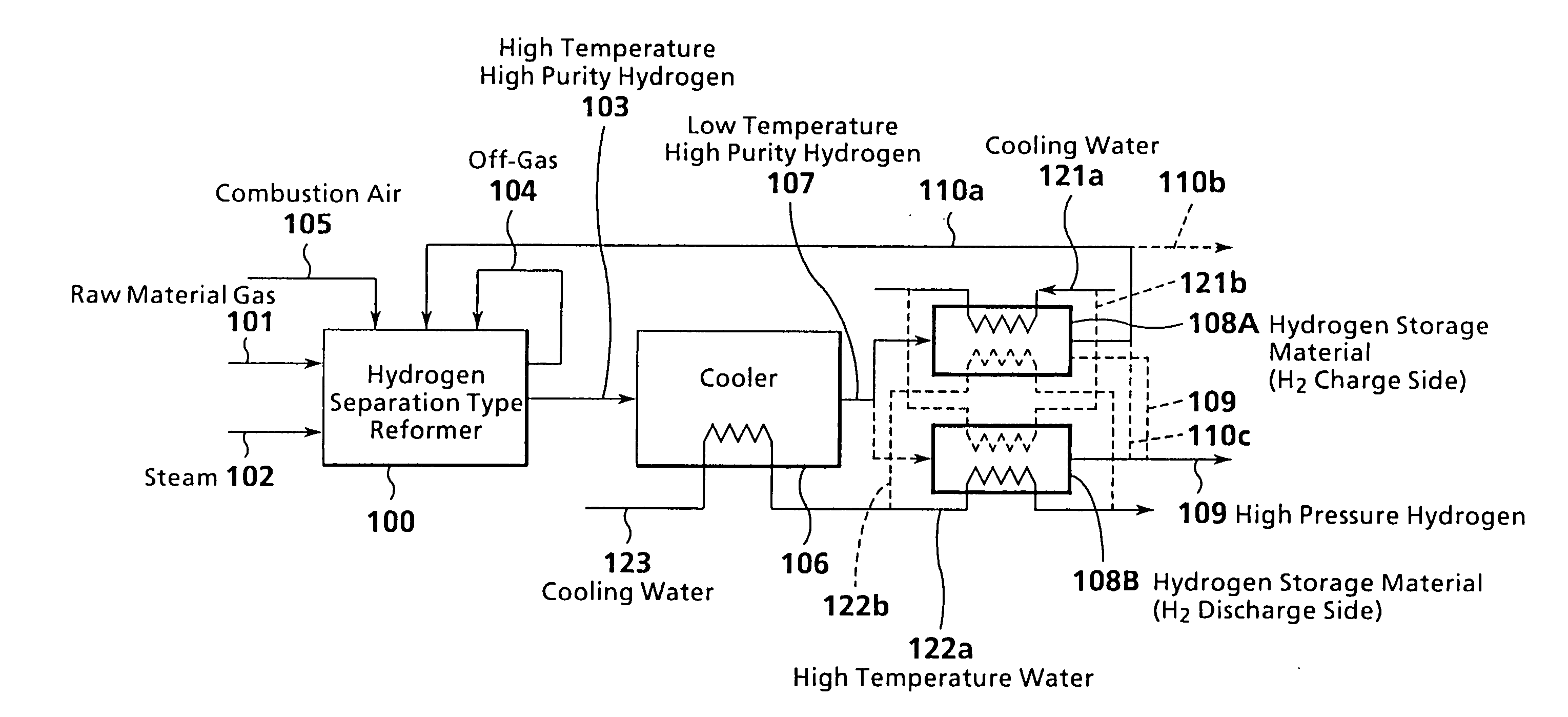

[0070] A first example of the invention will be explained based on the apparatus layout shown in FIG. 3. A hydrogen separation type reformer 100 had the structure shown in FIGS. 7 and 8, as with the preceding Embodiments. A heat exchanger, a cooler 106, was of a plate fin type, and used cooling water as a low temperature fluid 120a to cool high temperature high purity hydrogen 103. A hydrogen occluding material of a hydrogen storage / delivery means 108 was composed of two members of a hydrogen storing alloy of LaNi5.

[0071] Hydrogen was produced under the following concrete conditions in accordance with the flow shown in FIG. 3.

[0072] (1) Hydrogen Separation Type Reformer (100)

[0073] Main Constitution

[0074] The catalyst of the reformer 100 was an NiO catalyst in particle form, and the hydrogen separation membrane was made of a Pd alloy. The membrane area was 0.68 cm2.

[0075] Operating Conditions

[0076] The reaction temperature of the reformer was 550° C., and the reaction pressure...

example 2

[0085] A second example of the invention will be explained based on the apparatus layout shown in FIG. 3.

[0086] (1) Hydrogen Separation Type Reformer (100)

[0087] The constitution and operating conditions were the same as in Example 1.

[0088] (2) Cooler (106)

[0089] The same constitution and operating conditions as in Example 1 were adopted, except that the outlet temperature of low temperature high purity hydrogen 107 in the cooler 106 was 80° C.

[0090] (3) Hydrogen Storing Alloy

[0091] The same constitution and operating conditions as in Example 1 were adopted.

[0092] (4) Amount of Hydrogen Production

[0093] When the high purity hydrogen outlet temperature was 40° C. as in Example 1, the amount of hydrogen production was 3.0 m3 N / h. When the high purity hydrogen outlet temperature was 80° C., on the other hand, the amount of hydrogen production was 2.0 m3 N / h.

example 3

[0094] A third example of the invention will be explained based on the apparatus layout shown in FIG. 5.

[0095] A hydrogen separation type reformer 100, a cooler 106, and a hydrogen storage / delivery means 108 had the same constitutions as in Example 1. A pressure regulator 130 comprises a pressure regulating valve, and mitigates a rapid pressure fall at the start of hydrogen occlusion by the hydrogen storage / delivery means 108. Thus, the pressure regulator 130 curbs a rapid pressure change of low temperature high purity hydrogen 107 flowing out of the cooler 106.

[0096] Hydrogen was produced under the following concrete conditions:

[0097] The constitutions and operating conditions of the hydrogen separation type reformer 100, cooler 106, and hydrogen storage / delivery means 108 were the same as in Example 1.

[0098]FIG. 6 shows changes in the pressure of low temperature high purity hydrogen during hydrogen occlusion. Regulation of the pressure results in the mitigation of a rapid pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com