Stirling cooling device, cooling chamber, and refrigerator

a cooling device and cooling chamber technology, applied in the direction of cooling fluid circulation, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of poor heat transmission efficiency, high volatile, and use of ethanol, and achieve the effect of efficient transfer, efficient release, and improved heat transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

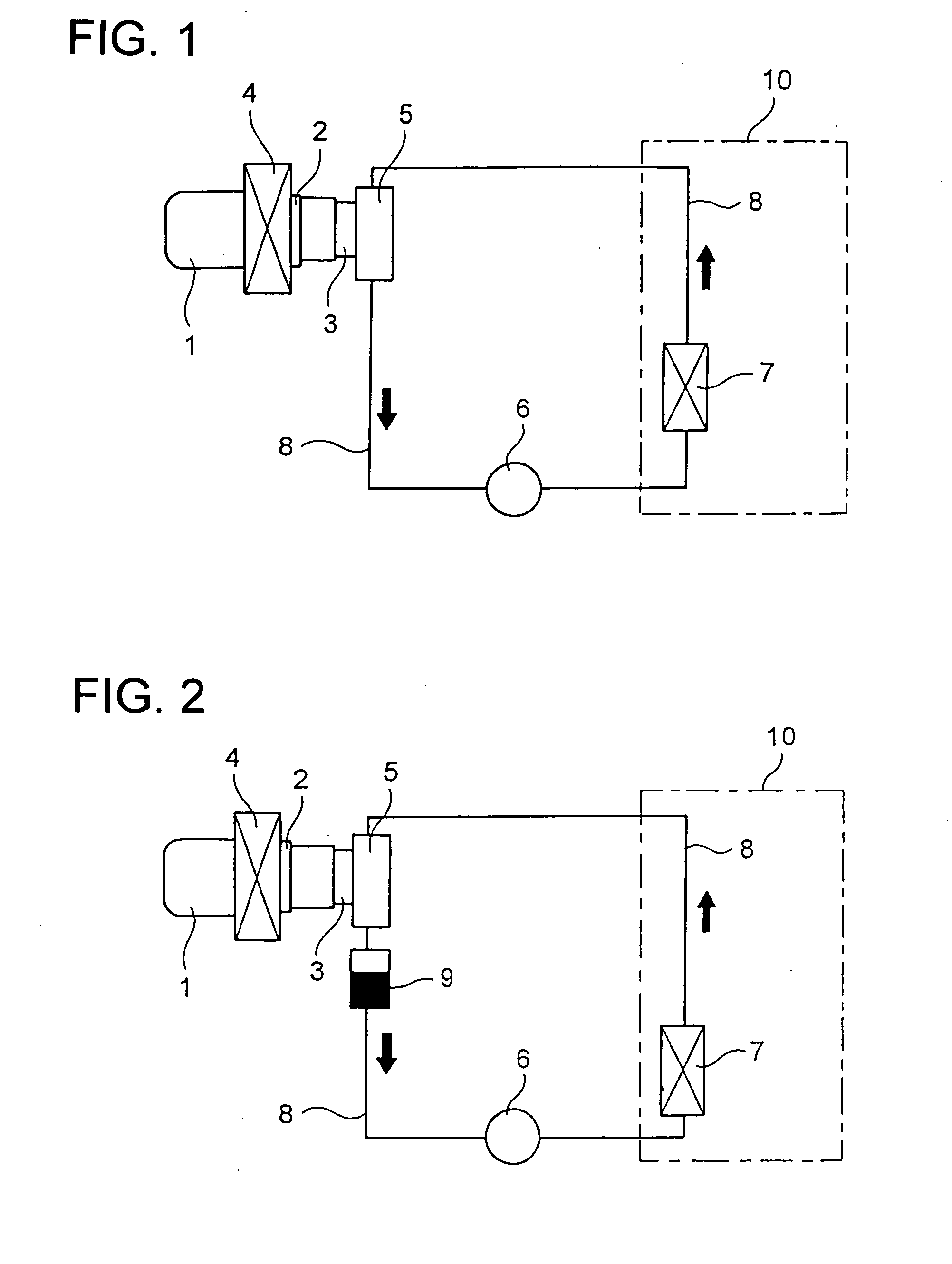

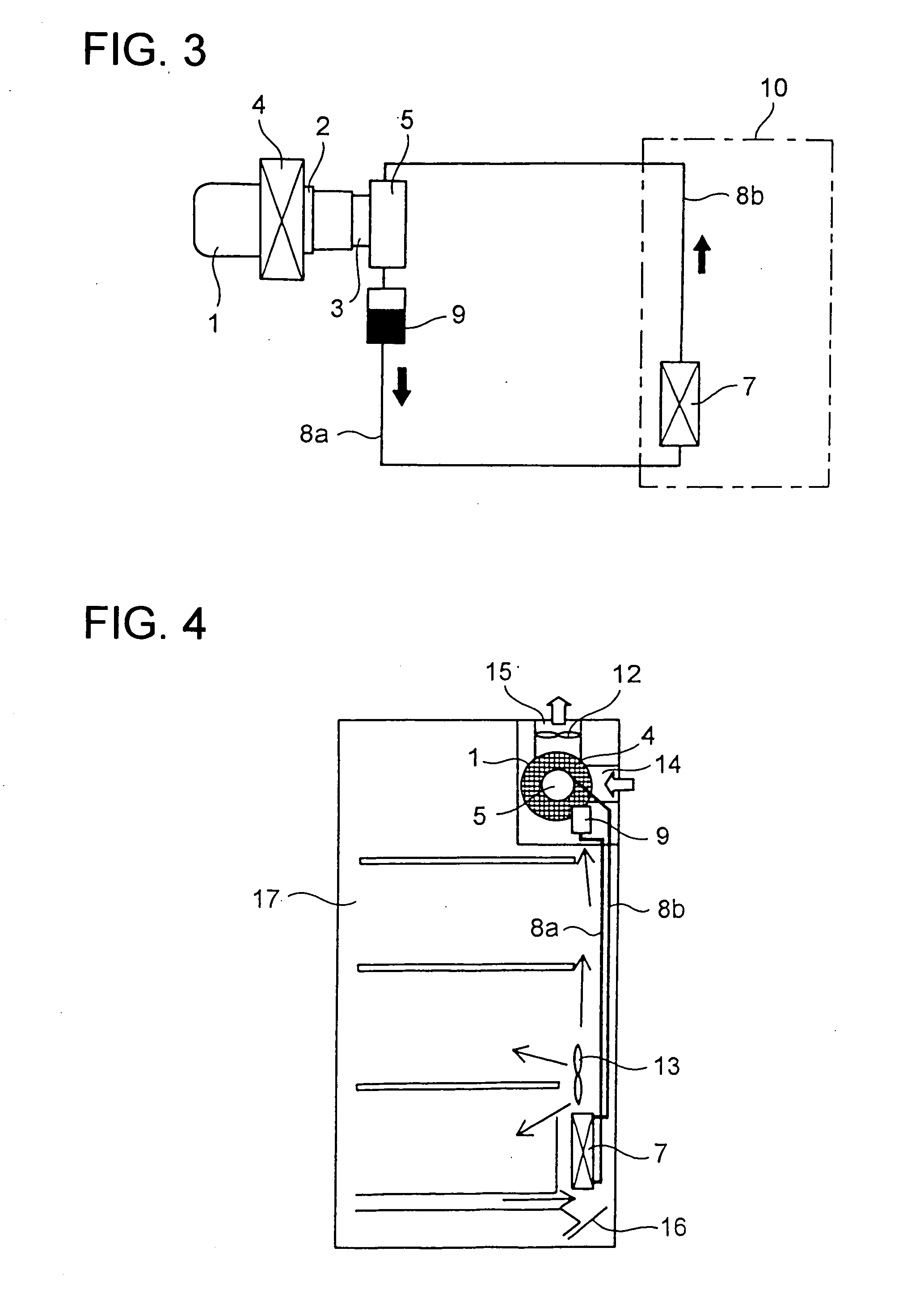

first embodiment

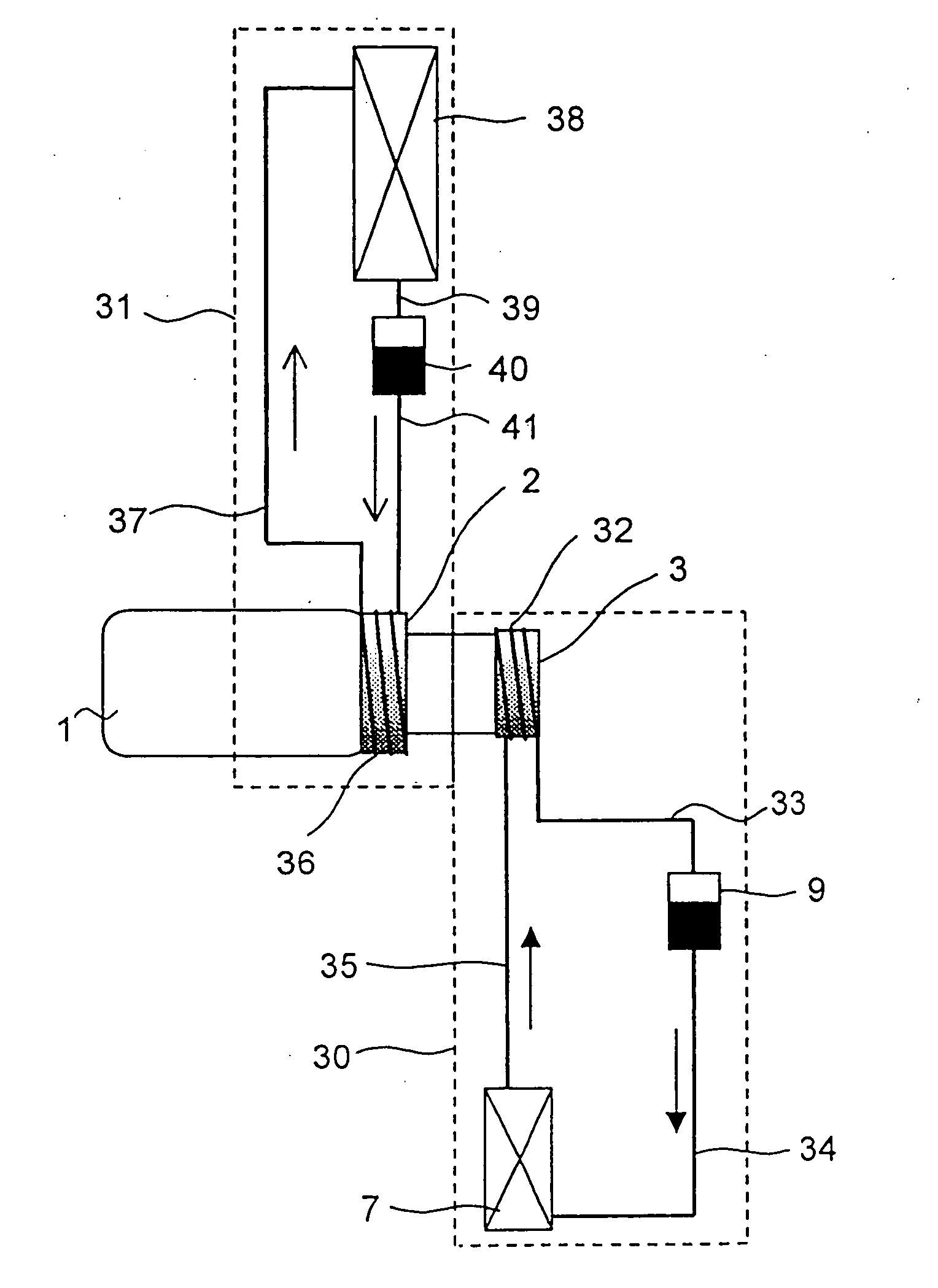

[0045] In the figure, arrows indicate the direction of the flow of the refrigerant. In this embodiment, carbon dioxide is used as the refrigerant. The configuration and operation of the Stirling chiller 1 shown in FIG. 2 are the same as in the first embodiment described above, and therefore its explanations will not be repeated.

[0046] When the linear motor (not shown) is driven, on the principle described earlier, waste heat is transferred to the high-temperature portion 2 of the Stirling chiller 1, raising the temperature of the high-temperature portion 2, and simultaneously cryogenic cold is produced in the low-temperature portion 3. Then, in the high-temperature-side heat exchanger 4 arranged so as to be in contact with the high-temperature portion 2, the waste heat is released out of the Stirling chiller 1 by air or water used as a heat carrier.

[0047] Simultaneously, the circulation pump 6 is also driven so that the refrigerant is circulated around the refrigerant circulation c...

fifth embodiment

[0083] In this way, by incorporating the chiller system of the fifth embodiment in a large, horizontal-type refrigerator, it is possible to effectively exploit the height of the refrigerator in the arrangement of the low-temperature-side heat exchanger portion 30 and the high-temperature-side heat exchanger portion 31. Moreover, by arranging the freezer compartment 46 nearest to the low-temperature-side evaporator 7 and arranging the vegetables compartment 45 under the refrigerator compartment 44, it is possible to effectively use the cold air inside the refrigerator chamber of the refrigerator 42.

[0084] Industrial Applicability

[0085] As described above, according to the present invention, the use of latent heat obtained through vaporization and liquefaction of the refrigerant contributes to better heat transmission efficiency than when sensible heat is exploited. Thus, cold is efficiently transferred to inside the refrigerator or cooler chamber, or heat is efficiently released to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com