Method for manufacturing coil-embedded dust core and coil-embedded dust core

a technology of dust core and coil, which is applied in the field of manufacturing coilembedded dust core and coilembedded dust core, can solve the problems of coil damage, difficult compression,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0133] Thirty samples of the coil-embedded dust core having a core size of 12.5 mm long×12.5 mm wide×3.5 mm thick were made according to the following procedure:

[0134] The following were prepared: [0135] Magnetic powder: Permalloy powder manufactured through atomizing method (45% Ni—Fe; mean particle size 25 μm) [0136] Insulating material: silicone resin (SR2414LV by Toray Dow Corning Silicone Co., Ltd.) [0137] Lubricant: aluminum stearate (SA-1000 by Sakai Chemical Industry)

[0138] Next, 2.4 wt % of the insulating material was added to the magnetic powder, and these were mixed for 30 minutes at room temperature using a pressure kneader. Following this, the mixture was exposed to air and dried for 30 minutes at 150° C., thereafter 0.4 wt % of the lubricant was added to the dried magnetic powder and mixed for 15 minutes in a V mixer.

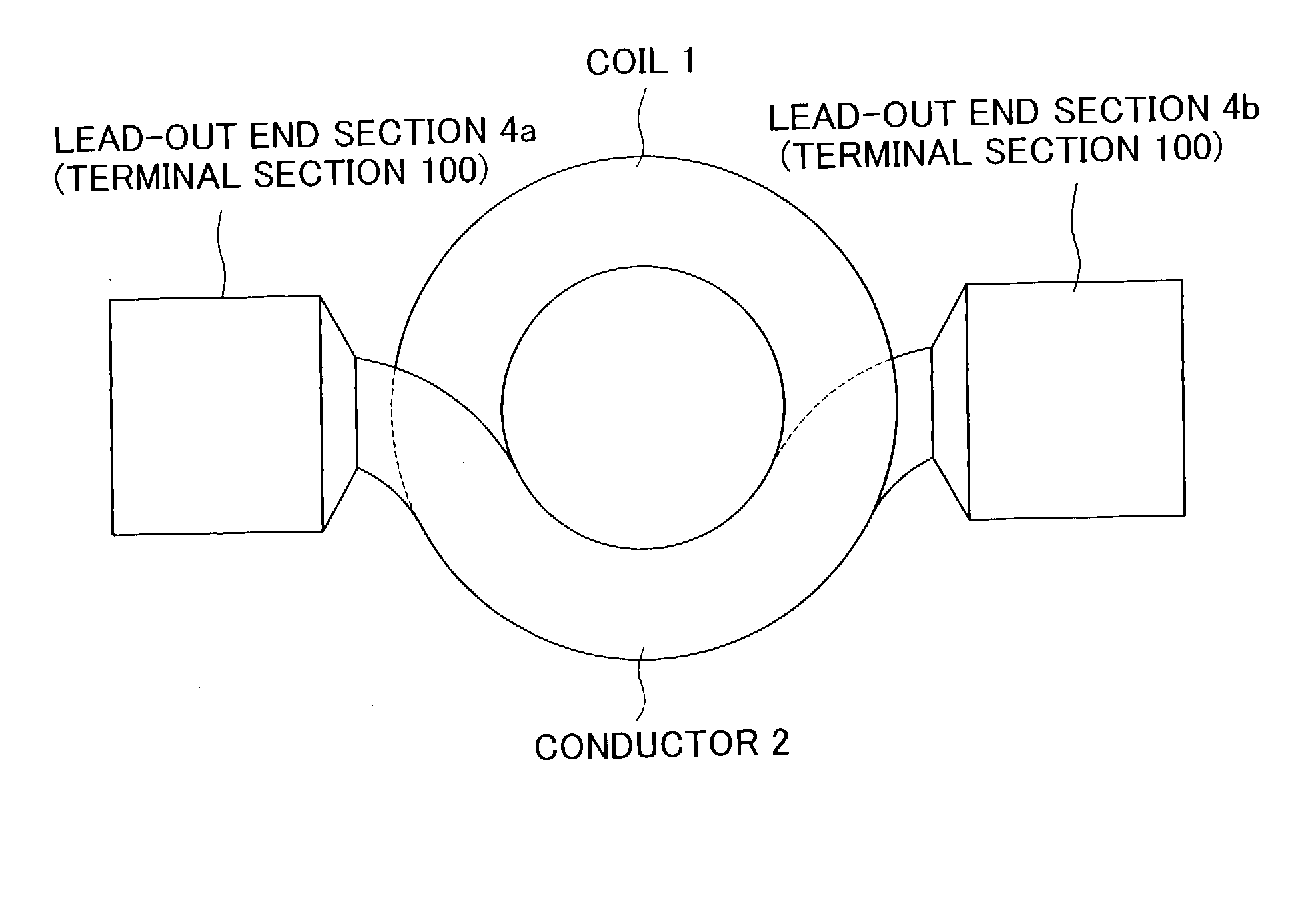

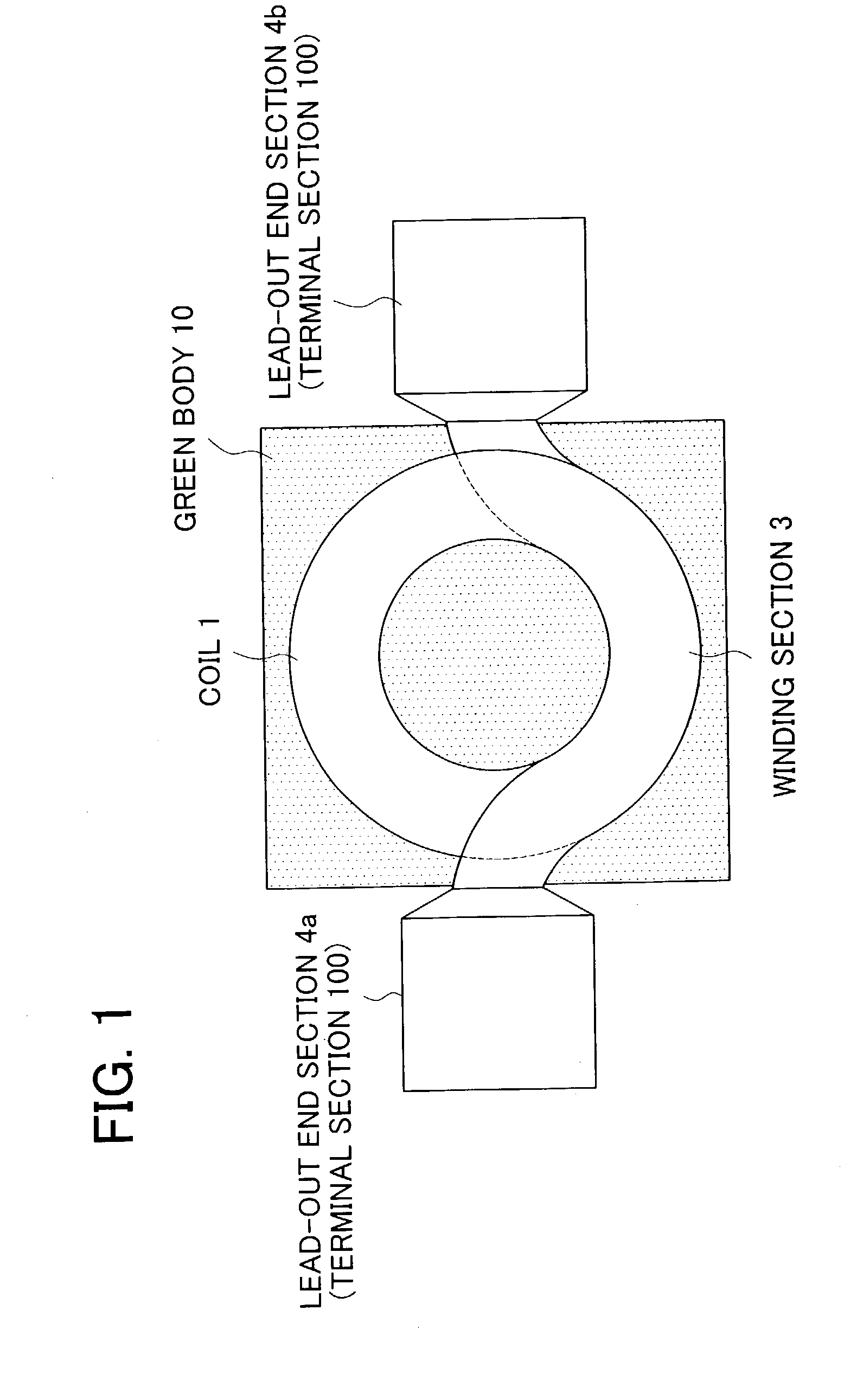

[0139] Subsequently, compressing was performed according to the procedure in FIG. 13A to FIG. 15D, and 30 compacted bodies are made. The coil 1 is form...

example 2

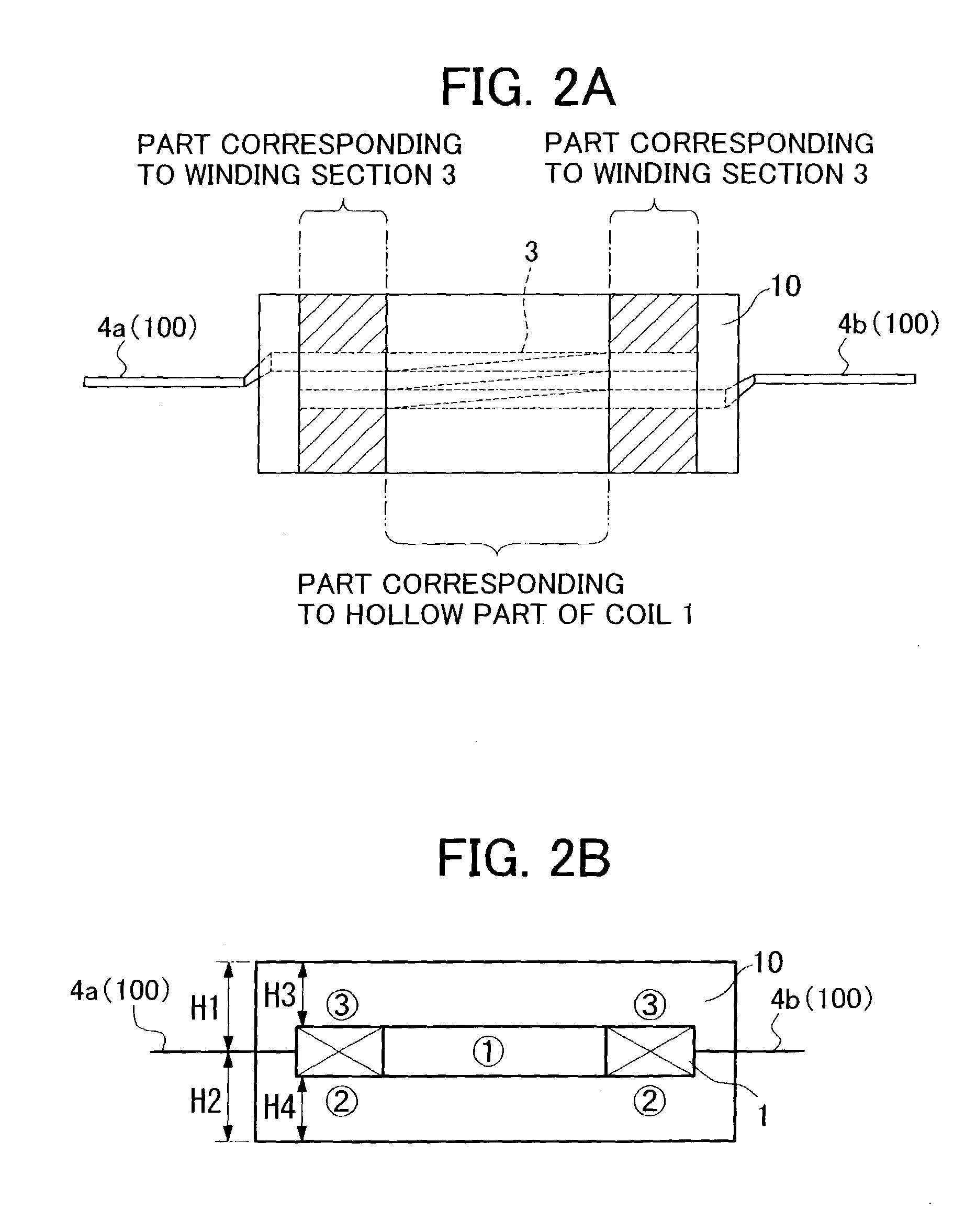

[0153] Out of the thirty samples made in the example 1, twenty samples were broken and the densities of the parts corresponding to the winding sections 3 of the coils 1 and the densities of the hollow parts of the coil 1 shown in FIG. 2A were measured using an Archimedean method with silicone oil. The result is shown in Table 1. Since the weight of each part is small, each part was taken out from twenty samples, and was measured together. The specific gravity of silicone oil is 0.817.

TABLE 1InIn airsiliconeDensity(g)oil (g)(g / cm3)Density of part8.5107.4416.50corresponding to windingsection 3 of coil 1Density of part7.2496.3276.42corresponding to hollowpart of coil 1

[0154] As shown in Table 1, the density of the part corresponding to the winding section 3 of the coil 1 shown in FIG. 2A was 6.50 g / cm3, and the density of the part corresponding to the hollow part of the coil 1 was 6.42 g / cm3. Namely, the difference between the density of the part corresponding to the winding section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com