Wavelet-based artificial neural net combustion sensing

a neural net and wavelet technology, applied in the direction of fuel injection control, measurement devices, instruments, etc., can solve the problems of difficult to perform a straightforward interpretation of an ionization signal created as an output of the combustion process, the inability to use an ionization signal for engine control, and the difficulty of complete interpretation and utilization of the ionization signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

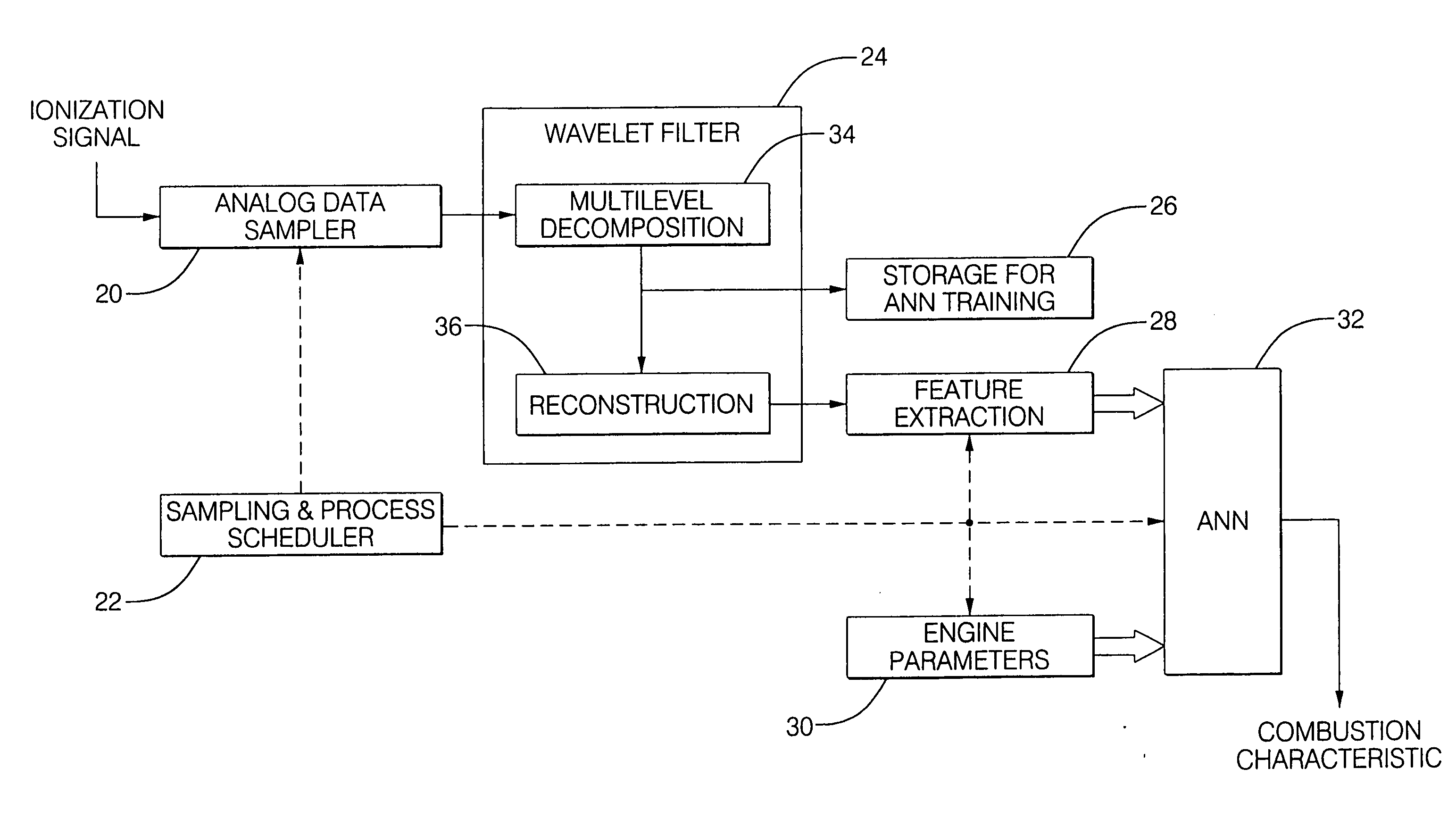

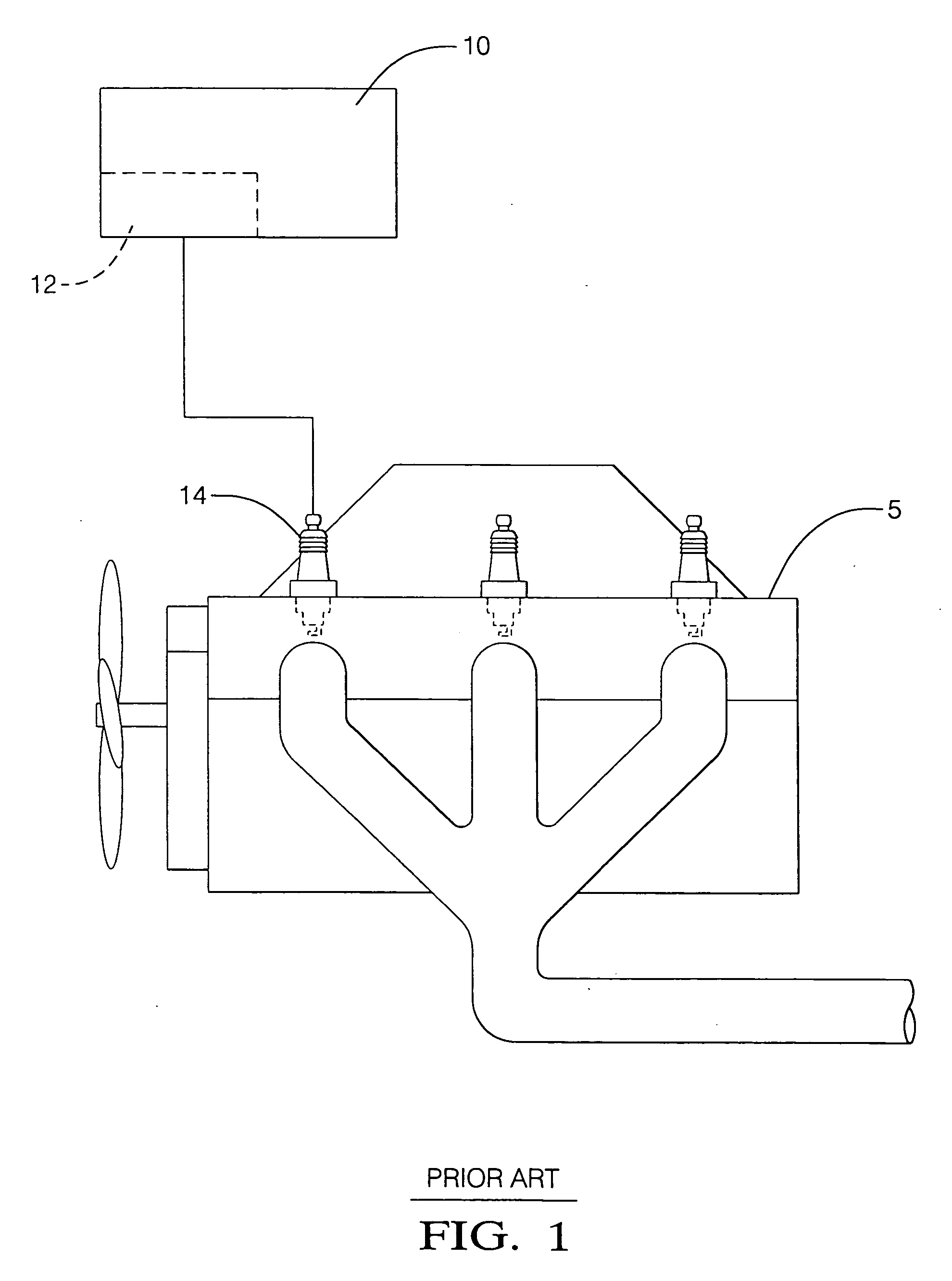

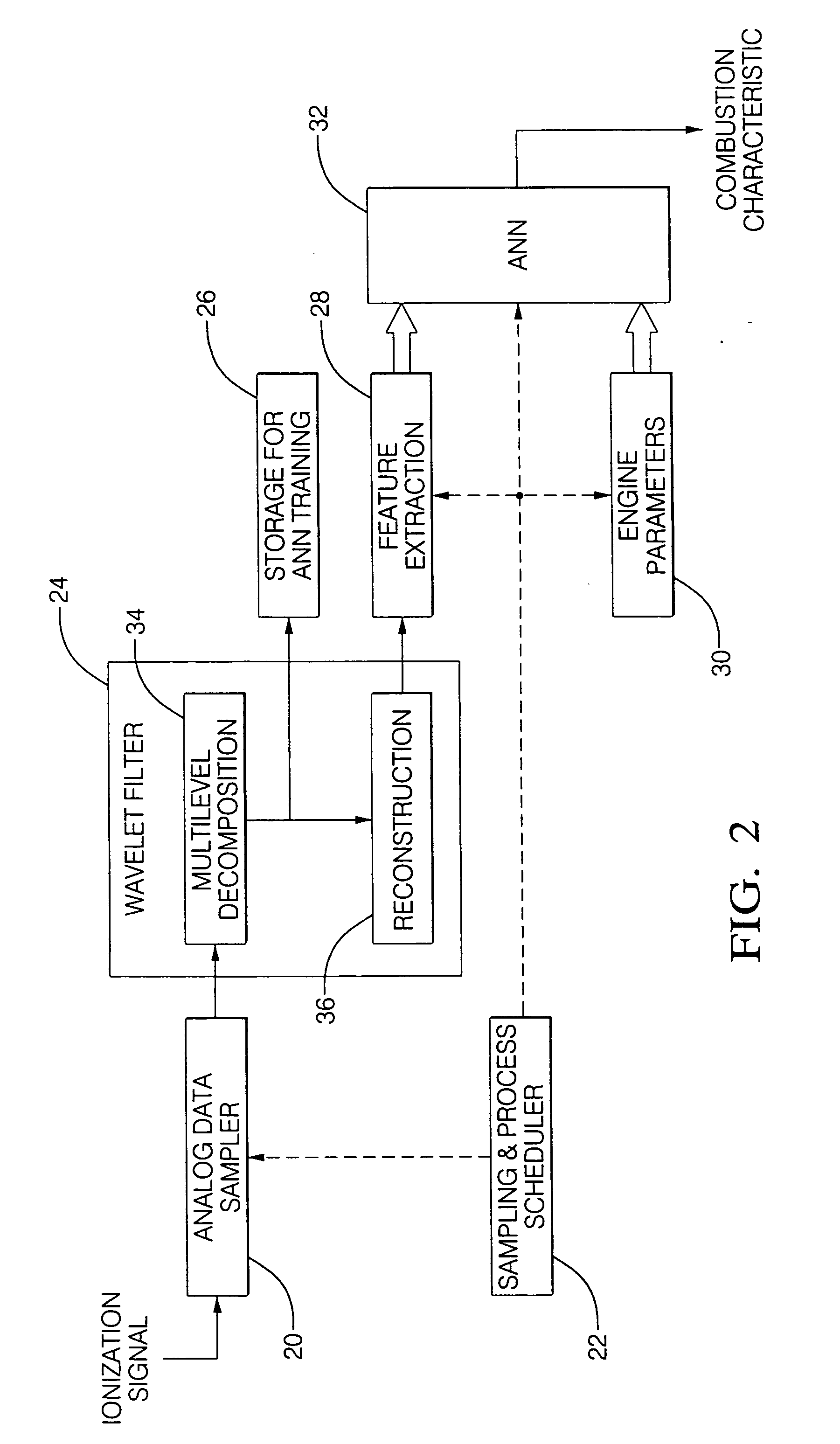

Referring now to the drawings, wherein the showings are for the purpose of illustrating the preferred embodiment of the invention only and not for the purpose of limiting the same, FIG. 1 shows an internal combustion engine 5 and controller 10 which have been constructed in accordance with an embodiment of the present invention. In this embodiment, the internal combustion engine is a spark-ignition engine. The internal combustion engine 5 is comprised of at least one cylinder containing a piston that is operably attached to a crankshaft at a point that is eccentric to an axis of rotation of the crankshaft. There is a head at the top of the piston containing valves for intake and exhaust air and a spark plug. A combustion chamber is formed within the cylinder between the piston and the head. A combustion charge comprising a combination of air and fuel is inlet through the intake valve into the combustion chamber, and is ignited by the spark plug, according to predetermined condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion | aaaaa | aaaaa |

| mass fraction | aaaaa | aaaaa |

| combustion characteristic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com